Repairs are not an easy task.But the huge selection of modern building materials makes it possible not only to carry out repairs quickly, but also to do it yourself, without hiring workers. Self-leveling screed is very convenient inuse since no effort is required to level it. During any repair, an important step will be the correct finishing of the floor surface. Self-leveling floor screed will help to properly prepare the surface for further work. The floor must be leveled - this is a prerequisite for creating any finishing coating, be it painting, laying tiles or laminate, parquet.

Self-leveling screed is very convenient inuse since no effort is required to level it. During any repair, an important step will be the correct finishing of the floor surface. Self-leveling floor screed will help to properly prepare the surface for further work. The floor must be leveled - this is a prerequisite for creating any finishing coating, be it painting, laying tiles or laminate, parquet.

How to prepare the foundation for a self-leveling floor?

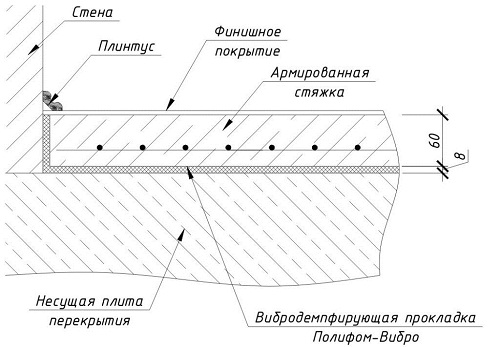

Floor screed diagram.To obtain a good result, the floor surface must first be properly processed. There should be no large holes, cracks through which the special filling mixture can leak, and debris: it will prevent the floor and the prepared composition from adhering properly. After thorough cleaning, the floor will need to be primed. Priming is done to enhance waterproofing. If the surface is very weak, a reinforcing mesh is additionally used to strengthen it, but in this case the primer layer must be thicker. The mesh must be completely hidden by this mixture - the layer thickness is usually 1 cm. To obtain a smooth horizontal surface, beacons are used. They should not be wooden: this material has the ability to absorb liquid from the primer mixture and deforms. For beacons, it is better to choose special beacon slats; improvised materials, such as pieces of profiles or iron pipes, will also do. Beacons are installed as follows:

Floor screed diagram.To obtain a good result, the floor surface must first be properly processed. There should be no large holes, cracks through which the special filling mixture can leak, and debris: it will prevent the floor and the prepared composition from adhering properly. After thorough cleaning, the floor will need to be primed. Priming is done to enhance waterproofing. If the surface is very weak, a reinforcing mesh is additionally used to strengthen it, but in this case the primer layer must be thicker. The mesh must be completely hidden by this mixture - the layer thickness is usually 1 cm. To obtain a smooth horizontal surface, beacons are used. They should not be wooden: this material has the ability to absorb liquid from the primer mixture and deforms. For beacons, it is better to choose special beacon slats; improvised materials, such as pieces of profiles or iron pipes, will also do. Beacons are installed as follows:

- find the highest point on the surface;

- mark it with a lighthouse;

- put beacons with a level (the distance between them should be about one and a half meters) and fix it to the solution;

- make markings on the walls.

The screed is leveled using a special toolwith a spiked roller. The primer layer must be completely dry before pouring the self-leveling floor. In the absence of a special primer mixture, a floor leveling compound is sometimes used. To do this, mix the powder and water together until it is not very thick. The technology of installing a self-leveling floor is not particularly difficult. The floor itself consists of a subfloor, i.e. the base, a primer layer and a self-leveling mixture. Return to contents</a>

The screed is leveled using a special toolwith a spiked roller. The primer layer must be completely dry before pouring the self-leveling floor. In the absence of a special primer mixture, a floor leveling compound is sometimes used. To do this, mix the powder and water together until it is not very thick. The technology of installing a self-leveling floor is not particularly difficult. The floor itself consists of a subfloor, i.e. the base, a primer layer and a self-leveling mixture. Return to contents</a>

How to prepare the staff?

To obtain a smooth surfaceSelf-leveling floors are used most often. This technology is not particularly expensive, not labor-intensive and quite simple. When preparing the mixture for pouring, it is better to pour the powder into water. If you pour liquid into powder, you will not be able to obtain a homogeneous mass. The screed can be prepared in a regular bucketusing a drill and a special attachment. You can mix the powder manually, but it is much more convenient to do this with special tools. You need to pour the self-leveling floor while the mixture is still in a liquid state, but keep in mind that the mass thickens quickly. Therefore, mix it so that you have time to cover a certain area of the floor with it. The hardening mixture cannot be diluted with water - this violates the technology of creating a self-leveling floor. Self-leveling screed can be arranged in cases where the difference in height on the surface is no more than 1-2 cm. In other cases, the screed will be expensive and will dry for a long time. When working, follow the rules by which a self-leveling floor should be arranged. The consumption of materials should be approximately 1.5 kg of powder per 1 sq. m of surface (screed thickness 1 mm). Take 6.5 liters of water per bag of mixture. You will get a liquid mass that is easy to work with. Return to the table of contents</a>

The screed can be prepared in a regular bucketusing a drill and a special attachment. You can mix the powder manually, but it is much more convenient to do this with special tools. You need to pour the self-leveling floor while the mixture is still in a liquid state, but keep in mind that the mass thickens quickly. Therefore, mix it so that you have time to cover a certain area of the floor with it. The hardening mixture cannot be diluted with water - this violates the technology of creating a self-leveling floor. Self-leveling screed can be arranged in cases where the difference in height on the surface is no more than 1-2 cm. In other cases, the screed will be expensive and will dry for a long time. When working, follow the rules by which a self-leveling floor should be arranged. The consumption of materials should be approximately 1.5 kg of powder per 1 sq. m of surface (screed thickness 1 mm). Take 6.5 liters of water per bag of mixture. You will get a liquid mass that is easy to work with. Return to the table of contents</a>

Tools for filling

To make a self-leveling floor screed, you will need the following equipment: The damper (edge) tape is laid along the perimeter of the floor area.

The damper (edge) tape is laid along the perimeter of the floor area.

- a container for stirring the mixture (you can do with a plastic bucket of 20 liters);

- mixer for construction;

- a putty knife, by means of which the mixture will be poured into corners and other inconvenient places;

- needle roller.

Crystallization of the mixture begins already afterhalf an hour after preparation, so you need to act quickly. Pour the solution onto the prepared area, then take a spatula and distribute the mixture over the surface as evenly as possible. After this, the composition must be rolled with a needle roller. This will help to remove air bubbles from the applied layer, due to which the strength of the floor will deteriorate significantly in the future. Return to contents</a>

How to count the kneading?

If you carefully follow the technology,made from a special mixture will not cost that much. The mix for different areas of the surface may differ - it all depends on its relief. One standard bag is enough for one mix. With the addition of water, the volume is about twenty liters, which must be poured onto the floor, after which the mass is leveled. Joints on the surface of the liquid mixture will not be noticeable. The mass dries quickly, so when pouring, you need to hurry. You should not make a larger mix at a time. At the thinnest place, the self-leveling floor screed should be 5 mm thick, and not less. Otherwise, this is a violation of the technology. The mixture dries completely in a period of three days to two weeks. You can arrange the finishing coating on top only when the distributed composition has completely dried. This way its integrity is not violated, mold does not form. Return to the table of contents</a>

Frequent errors in the implementation of floor screed

This type of floor is called self-leveling.because when the prepared mixture spreads, a perfectly smooth surface is formed. But the composition must be helped to spread correctly. For example, if the mixture does not reach the corner, it should be leveled, stretched with a spatula. When choosing a needle roller, it should be taken into account that the needles should be a couple of millimeters higher than the pouring level. Such a roller will not shift the mixture on the floor when smoothing. It is necessary to prepare the flaps in advance and think about the height of the threshold, otherwise the mass may spill over the edge. If the threshold looks quite high from the outside, it should be remembered that this impression can be deceptive. It is better to put up barriers in advance than to eliminate the consequences later. Before pouring, it is necessary to measure the heights of the room. Sometimes it happens that a small bump sticks out in the middle of the floor, which is not very noticeable to the eye, but for a self-leveling screed it will be an annoying omission. The bulge is usually noticed after the work is finished, and in this case it is impossible to talk about the ideal smoothness of the floor. Making a self-leveling screed is a simple and quite interesting process, but for speed it is better to do the work not alone, but with assistants.