According to statistics, it was revealed thatthe cost of LED lamps has dropped significantly. Such indicators have led to an increase in the purchase of highly economical lighting devices for private homes and apartments. Those who are good with a soldering iron will not need to go to the store to furnish their home, as they can create a lamp with their own hands, without resorting to factory products. In this way, you can save a large amount of money and choose a design for the device that will match the interior of the apartment. LED lamp diagram.LEDs have their own peculiarity, which consists in the constant current mode and low voltage. Therefore, such devices as power supplies are mainly used to carry out the lighting process. Some people solder electrical circuits on boards themselves, which is not so easy, especially for those who are not familiar with this field of activity. When creating a lamp with your own hands, a lamp or any other lighting device, you need to take into account the fact that one third of such a unit as rated power will go to converting the luminous flux, while the remaining parts are needed for heat loss. It is important to remember that when LEDs overheat, their service life may be reduced. When assembling any LED structure yourself, heat must be removed from the entire structure during power supply.

LED lamp diagram.LEDs have their own peculiarity, which consists in the constant current mode and low voltage. Therefore, such devices as power supplies are mainly used to carry out the lighting process. Some people solder electrical circuits on boards themselves, which is not so easy, especially for those who are not familiar with this field of activity. When creating a lamp with your own hands, a lamp or any other lighting device, you need to take into account the fact that one third of such a unit as rated power will go to converting the luminous flux, while the remaining parts are needed for heat loss. It is important to remember that when LEDs overheat, their service life may be reduced. When assembling any LED structure yourself, heat must be removed from the entire structure during power supply.

Which LEDs should I use?

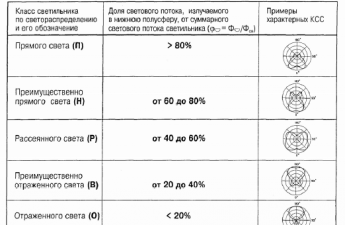

Table of LED types.Initially, it is advisable to select a specific type of LED that will be required. If we consider high-power and low-power, the first type is much more profitable, due to the fact that labor intensity is higher. The ratio of low-power to high-power is 20:1. Based on such indicators, we can conclude that with low-power LEDs, much more soldering will be required. Among high-power LEDs, there are a couple of varieties, some of which are intended for lead-out installation work, and others - for surface-mounted ones. In most cases, lead-out ones are used, since installation work with them is carried out much faster. Return to contents</a>

Table of LED types.Initially, it is advisable to select a specific type of LED that will be required. If we consider high-power and low-power, the first type is much more profitable, due to the fact that labor intensity is higher. The ratio of low-power to high-power is 20:1. Based on such indicators, we can conclude that with low-power LEDs, much more soldering will be required. Among high-power LEDs, there are a couple of varieties, some of which are intended for lead-out installation work, and others - for surface-mounted ones. In most cases, lead-out ones are used, since installation work with them is carried out much faster. Return to contents</a>

Power Supplies

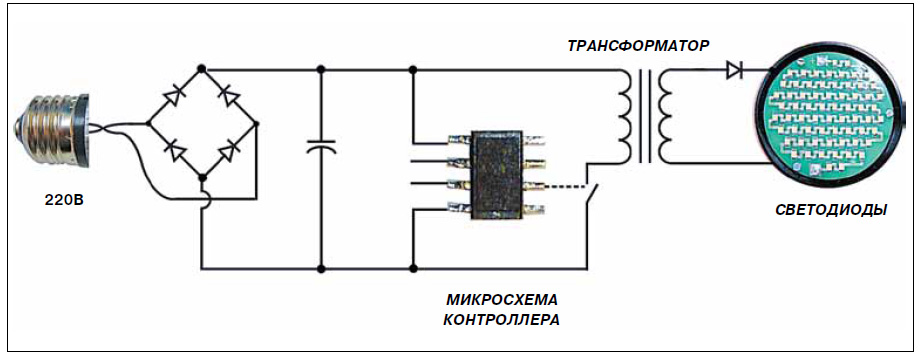

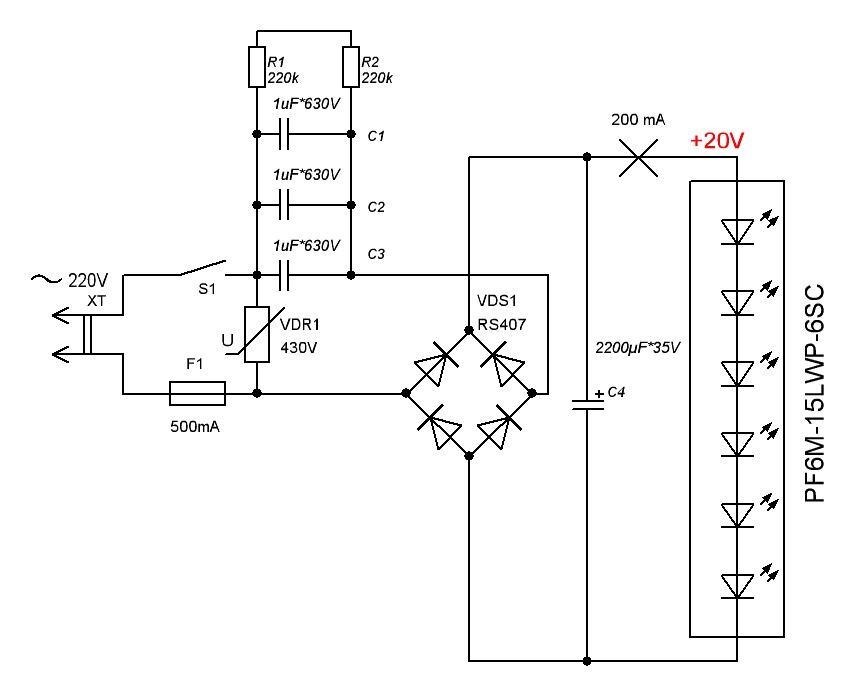

For the longevity of LEDs, excellent quality is required.driver, or in other words, a power source. The driver can be cased or uncased, with or without galvanic isolation. If we consider the reworking of lamps, it is advisable to use a caseless driver with galvanic isolation. The caseless type is very useful because it is compact in size and also has a lower heating level. But there are also certain disadvantages that are manifested in the difficulty of fastening. The use of galvanic isolation is usually required to ensure safety, since in this case you can avoid electric shock. In the absence of such technology, some receive minimal electric shocks. Electrical diagram of LED lamp.When choosing drivers, it is advisable to pay attention to the indication of the minimum and maximum number of LEDs that can be connected. If such data is missing, then it is worth looking at the output voltage indicators of the power source. The power source can be of two types, one of which consists of an electromagnetic interference filter, and the second, accordingly, does not have one. Devices that do not have filters, to a greater extent have interference from electromagnetic waves and frequency transmission to receivers. Return to contents</a>

Electrical diagram of LED lamp.When choosing drivers, it is advisable to pay attention to the indication of the minimum and maximum number of LEDs that can be connected. If such data is missing, then it is worth looking at the output voltage indicators of the power source. The power source can be of two types, one of which consists of an electromagnetic interference filter, and the second, accordingly, does not have one. Devices that do not have filters, to a greater extent have interference from electromagnetic waves and frequency transmission to receivers. Return to contents</a>

Using a radiator for LEDs

In order to use the LED successfullyand for a long time, it is worth using radiators, since they are as important components of the process as power sources. The radiator must be made exclusively of aluminum. It is very easy to find such a material, since everyone has old aluminum dishes. In order to be able to dissipate heat from the LED, it is necessary to take into account the size of the area, and not the thickness. It is worth noting that fans are installed on computer coolers, since without such a device, heat from the LED will be removed at a minimum speed. Return to contents</a>

The process of making a lamp yourself

Before you start developing a lamp yourself, it is advisable to prepare all the necessary tools. In particular, it is advisable to acquire: Scheme of the lamp body.

Scheme of the lamp body.

- basic and spare LEDs;

- a microtransformer;

- multimeter;

- red LED light bulbs;

- Resistor by 100 Ohm;

- a 400 μF capacitor and 10 μF;

- a cartridge;

- degreaser;

- soldering iron;

- mounting glue;

- board;

- shade.

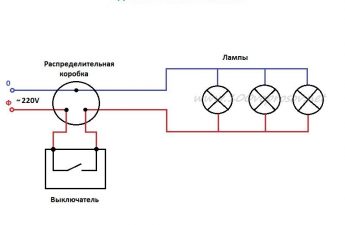

It is advisable to conduct a check firsteach LED that will be included in the circuit, and the quality of the supply voltage in the network cable. To carry out such a process, it is worth using a microtransformer. Thus, when setting up and testing the future lighting device, the adjustment will be much smoother. In order to measure whether the voltage drops with direct current and the effect on the resistor or not, and to accurately calculate the current of the diodes, a multimeter is used. As a rule, when self-assembling, they try to use six-volt lamps, but often you may need those designed for 12 volts. The diodes themselves must be of high quality to avoid an unpleasant bluish glow, which will not only spoil the appearance of the lamp, but also harm the eyes. Wiring diagram of LED parts on the housinglamp. The assembly diagram can be called very simple and without loss for the driver. The only drawback is the lack of insulation of the wires, that is, the LED lamp itself can be subject to electric shocks. Based on the latest data, it is worth considering that it is advisable to protect the lamp from falling, but subsequently the circuit can be modernized.

Wiring diagram of LED parts on the housinglamp. The assembly diagram can be called very simple and without loss for the driver. The only drawback is the lack of insulation of the wires, that is, the LED lamp itself can be subject to electric shocks. Based on the latest data, it is worth considering that it is advisable to protect the lamp from falling, but subsequently the circuit can be modernized.

If there is no possibility of purchasing a new onecartridge, it can be removed from the old lamp. To do this, you need to carefully break the bulb, and so that the socket part of the cartridge is not damaged. After this procedure, the cartridge itself should be protected and treated with a degreaser. It is important that before installation, the hole in the cartridge is checked again for the presence of lamp residues that can harm the future lighting system, and it is advisable to carry out additional treatment with acetone or alcohol. Return to contents</a>

Mounting the cartridge to the resistor and transistor

Next comes the soldering work.A tiny rectifier is installed using a soldering iron, and the materials must be prepared in advance and at hand. The surface must be processed without fail, and the actions themselves must be as precise and accurate as possible in order to exclude damage to the already installed parts. In order to carry out heat shrinkage, any type of mounting glue is used, since the material must be designed for such actions, and in no case for office purposes. Installing LED lamps is considered the most important and interesting moment in the entire assembly of the lamp. The basis will be a board purchased in advance or prepared from old devices. If it belonged to old designs, then, accordingly, the board must be cleaned of parts and various burrs. When conducting and connecting each contact, they should be checked and cleaned if the signal is not received. Very little remains - and the lamp will be able to please its creator. In order to complete the work, you just need to collect all the parts that are available. To be more precise, each part is soldered to the board and to the resistor device. Then everything is insulated with glue, the connections between the diodes are checked for proper light distribution.