It's become very stylish latelyuse multi-level plasterboard ceilings in your home interior. This design looks interesting and unusual. The design of such a ceiling allows you to choose and combine any lighting. Each level has its own individual color, or you can do everything in one tone. If you have the opportunity, talent, or simply the means, many order artistic painting for the ceiling. An interestingly designed ceiling surface can become the highlight of any living space. The multi-level ceiling structure is made of plasterboard.

The multi-level ceiling structure is made of plasterboard.

Some features

If you approach the installation of this system correctlydesign, you can visually play with the space and height of the room. If a specialist deals with this issue, he will be able to divide the room into zones only with the help of the correct construction and external design of a multi-level ceiling. This design has several functions: Materials required for installation.

Materials required for installation.

Some people are more comfortable when they arein a room with low ceilings, while others - vice versa. Thanks to the system of multi-level ceilings, everyone can solve this issue in the way that is most convenient for them. And the lighting itself - in the plane itself or on the ceiling step - will help solve this problem. You can also add other components, such as glass or a mirror. There are many options, everything is limited by your imagination. Return to the table of contents</a>

Technology of multi-level ceiling from plasterboard

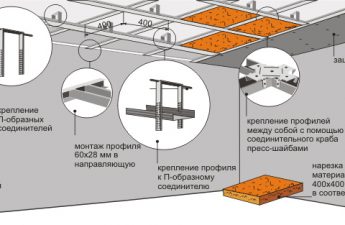

Drywall is a commonly usedfinishing material. This is due to the fact that it is quite easy to install and allows you to save working time. GKL do not require special preparation of the base surface, after them the surface is already ready for finishing work. Ceilings made of plasterboard are built much faster than they are then finally brought to the proper form. Multi-level ceilings are designed in several stages: Scheme of multi-level suspended ceiling.

Scheme of multi-level suspended ceiling.

Before you start making ceilings fromplasterboard with your own hands, you should know that such a design is only permissible in rooms where the overall humidity level does not exceed 70%. Otherwise, you should take care of the brand of material that will be more moisture resistant, or simply use gypsum fiber. The humidity of the working base itself should not be more than 8%. Return to contents</a>

Preparatory moments

In order for plasterboard ceilings and the structure itself to serve for a long time and reliably, it is necessary to take into account some preparation points:

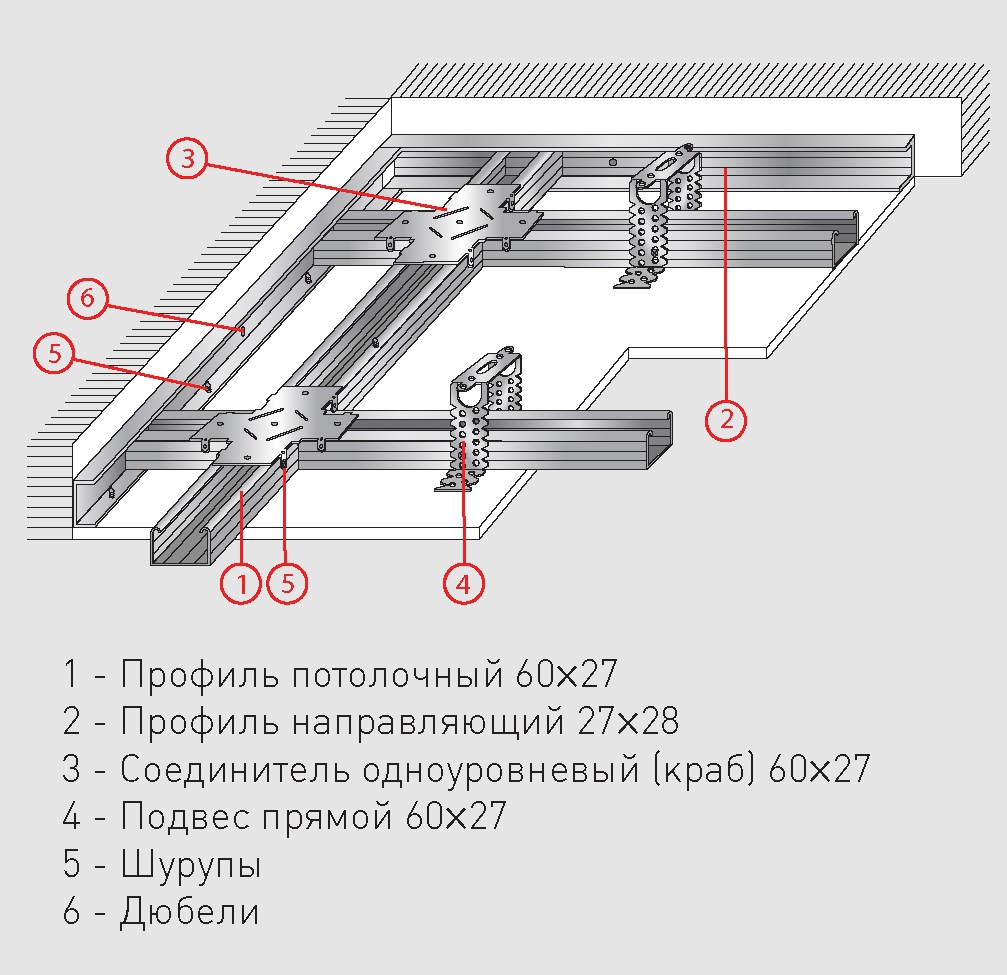

Scheme of the plasterboard ceiling frame.It is necessary to ensure that the ventilation and electrical wiring have already been laid out according to the wishes. The outlet of the lamps from the plasterboard must correspond to the presence of wiring there. The sleeves of the ventilation and air conditioning systems must also be in place. After the sheathing sheets are installed, it will be difficult to make any changes. When working with plasterboard, there is a risk of dust getting into the eyes and respiratory tract. Therefore, simple respiratory masks and safety glasses are used for this purpose. It is also necessary that the work room is constantly ventilated, so that the dust will not stagnate in the room for a long time, and therefore cause inconvenience. When using certain tools, you should know their correct purpose. For example, if the tool is meant to be electric, then it is necessary to minimize the humidity around.

Scheme of the plasterboard ceiling frame.It is necessary to ensure that the ventilation and electrical wiring have already been laid out according to the wishes. The outlet of the lamps from the plasterboard must correspond to the presence of wiring there. The sleeves of the ventilation and air conditioning systems must also be in place. After the sheathing sheets are installed, it will be difficult to make any changes. When working with plasterboard, there is a risk of dust getting into the eyes and respiratory tract. Therefore, simple respiratory masks and safety glasses are used for this purpose. It is also necessary that the work room is constantly ventilated, so that the dust will not stagnate in the room for a long time, and therefore cause inconvenience. When using certain tools, you should know their correct purpose. For example, if the tool is meant to be electric, then it is necessary to minimize the humidity around. The plasterboard sheets are screwed to themetal frame. To make high-quality cuts, the blades must be sharpened, which means that they must be handled very carefully so as not to injure yourself. If the premises are characterized by increased fire hazard, the electricity must be turned off. The use of scaffolding, ladders, stepladders and other similar equipment requires careful work. Their legs must always be firmly installed on the support or surface. For ease of installation of a multi-level ceiling, the workplace must be clean. The accumulation of foreign objects and debris on the construction site guarantees a delay in work, and in some cases can lead to unpleasant moments. Return to contents</a>

The plasterboard sheets are screwed to themetal frame. To make high-quality cuts, the blades must be sharpened, which means that they must be handled very carefully so as not to injure yourself. If the premises are characterized by increased fire hazard, the electricity must be turned off. The use of scaffolding, ladders, stepladders and other similar equipment requires careful work. Their legs must always be firmly installed on the support or surface. For ease of installation of a multi-level ceiling, the workplace must be clean. The accumulation of foreign objects and debris on the construction site guarantees a delay in work, and in some cases can lead to unpleasant moments. Return to contents</a>

Multi-level ceiling system

The first thing you need to start working with isdrawing up a design drawing. If you are making plasterboard ceilings on several tiers with your own hands, then a drawing is simply a must. It will serve as a support in the work, and you can also use it to calculate potential errors at the planning level. Drawing of a multi-level plasterboard ceiling.First of all, you need to know the dimensions of the room where you plan to install multi-level plasterboard ceilings. At this stage, you need to take into account the presence of all the additional details that will need to be hidden later: a ventilation box, lighting wires, decorative elements and other utilities. A schematic drawing is drawn on paper. Professional construction teams transfer the diagram to the floor in full size to make the task easier. This makes the work much easier. On paper, you should mark the desired lighting points where the lamps will be mounted. The location of the electrical wires will directly depend on this. Return to contents</a>

Drawing of a multi-level plasterboard ceiling.First of all, you need to know the dimensions of the room where you plan to install multi-level plasterboard ceilings. At this stage, you need to take into account the presence of all the additional details that will need to be hidden later: a ventilation box, lighting wires, decorative elements and other utilities. A schematic drawing is drawn on paper. Professional construction teams transfer the diagram to the floor in full size to make the task easier. This makes the work much easier. On paper, you should mark the desired lighting points where the lamps will be mounted. The location of the electrical wires will directly depend on this. Return to contents</a>

Installation instructions for multi-level ceilings

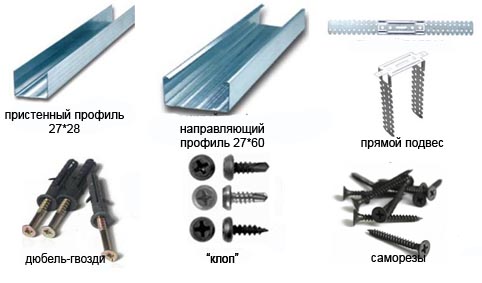

This design consists of a framebases on which panels and modules are attached. Because they will be attached at different levels, the impression of free space will be created. To install ceilings, you need to have the following tools:

- mites;

- Edge and peeling planer with a blade of 250 mm;

- Profile prosector;

- Needle roller;

- screwdriver or drill;

- construction roulette;

- knife;

- building level;

- a painting line;

- self-tapping screws.

Installation diagram of a multi-level ceiling made ofdrywall. Experts recommend using whole sheets of drywall, cutting them to a minimum. Long sections are used when there is a need to work with crossbars, posts and support beams. In this case, the sheet is cut to length. Using a tape measure, the necessary parameters of the elements are measured on the canvas. According to the marks, cuts are made with a knife. Drywall is a fairly soft material, since when you press on it, the necessary part can easily be separated from the canvas. If some places are not separated, this can be easily fixed with the same knife. Next, you need to calculate the amount of profile. Focusing on the drawing, the profile is attached 8-10 cm wider, while it is advisable to observe a step of 40 cm. This creates the frame of the first tier. But not the entire surface is sewn up with drywall. The canvas is attached only to the visible parts. This saves both time on the work and the material itself. The main profile should be fixed along the entire perimeter of the room on the walls so that additional ones can be attached to it. For correct measurements, you need to find the lowest point of the ceiling, then add another 25 mm to this value. Next, measure the resulting value on the walls, not forgetting to mark it in the corners. Since the plasterboard has its own thickness, 15 mm is added for safety. This way you can see at what level the first tier will be located. Then the first tier is covered with plasterboard, but only so that there is a reserve of 10-15 cm. In order for the screw to hit the profile exactly, reference lines are drawn on the plasterboard, which will indicate the location of the fastening. The first level is the base, so it is usually covered with whole sheets. About 60 screws should be used per sheet. This is the only way to achieve reliable fastening. Return to contents</a>

Installation diagram of a multi-level ceiling made ofdrywall. Experts recommend using whole sheets of drywall, cutting them to a minimum. Long sections are used when there is a need to work with crossbars, posts and support beams. In this case, the sheet is cut to length. Using a tape measure, the necessary parameters of the elements are measured on the canvas. According to the marks, cuts are made with a knife. Drywall is a fairly soft material, since when you press on it, the necessary part can easily be separated from the canvas. If some places are not separated, this can be easily fixed with the same knife. Next, you need to calculate the amount of profile. Focusing on the drawing, the profile is attached 8-10 cm wider, while it is advisable to observe a step of 40 cm. This creates the frame of the first tier. But not the entire surface is sewn up with drywall. The canvas is attached only to the visible parts. This saves both time on the work and the material itself. The main profile should be fixed along the entire perimeter of the room on the walls so that additional ones can be attached to it. For correct measurements, you need to find the lowest point of the ceiling, then add another 25 mm to this value. Next, measure the resulting value on the walls, not forgetting to mark it in the corners. Since the plasterboard has its own thickness, 15 mm is added for safety. This way you can see at what level the first tier will be located. Then the first tier is covered with plasterboard, but only so that there is a reserve of 10-15 cm. In order for the screw to hit the profile exactly, reference lines are drawn on the plasterboard, which will indicate the location of the fastening. The first level is the base, so it is usually covered with whole sheets. About 60 screws should be used per sheet. This is the only way to achieve reliable fastening. Return to contents</a>

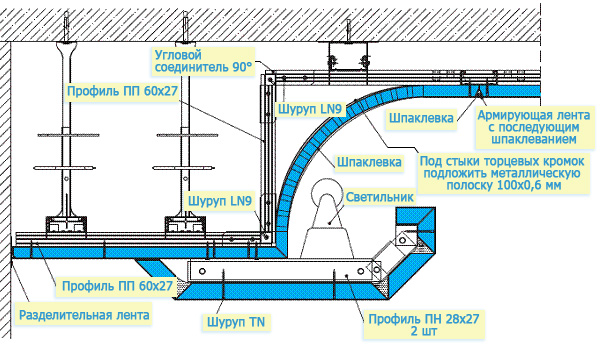

Concluding moments

In order for the second tier to be lower,a longer profile is taken. The corners are marked with a long building level, focusing on the lower edges of the second level. Then they are connected with a painter's cord. A guide profile is attached along the resulting line, which will mark the lower tier. At this stage, it is best to take care of where the lighting wires should go. Cut sheets of drywall are attached to the lower profiles. Next, all the seams must be sealed. To do this, the initially cut corners of the material are sanded with a plane, and then all the cracks and seams are sealed with plaster. If there are protruding places when fixing the material, then it is better to cut them off only after the entire level is completed. Then it will be possible to adjust the pattern of the ceilings. It should not be forgotten that the ends are sewn up. Wires are pulled out into pre-drilled holes, to which lighting fixtures are connected. In order for the drywall to easily accept coatings in the future, it is recommended to open it with a primer. After this, you can paint the ceilings and do any other work. So, it is not difficult to make multi-level ceilings yourself. The main thing is to remember that the more tiers you want, the more reliable the fastenings should be. If you save on the quality of materials, then there is a chance that such a ceiling will not last long and may even fall.