Many professionals consider plywood to be the bestrough base for the floor. This material is distinguished by its durability, it retains heat and is not subject to deformation. Due to the fact that plywood is made of wood, its ability to maintain a healthy and comfortable microclimate in the room. The technology of repairing the floor with plywood is quite simple, so if desired, you can do the work yourself, thereby preventing unnecessary costs. Plywood is often used today forleveling or installing a subfloor. If you are going to repair floors with plywood for the first time, it is very important to carefully study the instructions before starting the work process. Despite the relatively simple technology of repairing floors with plywood sheets, the task should be approached with full responsibility.

Plywood is often used today forleveling or installing a subfloor. If you are going to repair floors with plywood for the first time, it is very important to carefully study the instructions before starting the work process. Despite the relatively simple technology of repairing floors with plywood sheets, the task should be approached with full responsibility.

The stage of plywood laying and all about the way it is fastened

For fixing plywood sheets to the baseglue and dowels are used. The adhesive composition, which has a water base, is distinguished by the absence of a pungent odor, while it takes several days to dry. For those who planned to finish the floor repair in the shortest possible time, this option may not be suitable. Existing sizes of plywood sheets.Solvent-based glue requires shorter drying times, and many are put off by its sharp, unpleasant smell. If you decide to give preference to it, then after the floor repair is completed, the room must be well ventilated. The best option for repairing a floor with plywood is a two-component adhesive composition. It is worth noting that this method is very popular among high-class specialists. Return to contents</a>

Existing sizes of plywood sheets.Solvent-based glue requires shorter drying times, and many are put off by its sharp, unpleasant smell. If you decide to give preference to it, then after the floor repair is completed, the room must be well ventilated. The best option for repairing a floor with plywood is a two-component adhesive composition. It is worth noting that this method is very popular among high-class specialists. Return to contents</a>

Initial stages of repairing floors

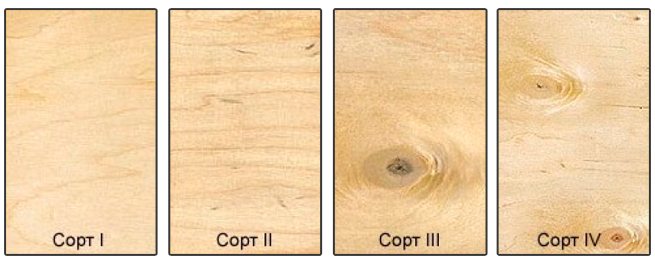

Floor repairs begin with the installation of a screed.For the installation of a floor screed, you can choose one of two methods: a) dry, b) wet. It should be noted that special requirements are imposed on the quality of the screed, first of all, all the conditions of the technology must be observed when performing the work. The base must be as smooth as possible, otherwise the coating may deform over time, a squeak will appear, which will significantly reduce the service life of the floors. Types of plywood.If the floor screed was made according to all the requirements of the technology, the humidity level of the base is not higher than 1% and the issue with thermal insulation and waterproofing is resolved, you can be sure that the finished floor will be dry, warm and will last a long time. Very often, plywood is used as a base for parquet (the best option in this case is FK 4/4). Many specialists prefer to use plywood sheets 1 cm thick for floor repairs; sheets 12 mm thick are also good. In addition to the fact that such material is quite durable, it is also flexible, and this is a very important condition, since plywood sheets take on a very large load. Plywood sheets consist of many layers, high humidity levels are contraindicated for them, otherwise they will begin to delaminate over time. That is why, before you start repairing floors with plywood, check the humidity of the concrete floors. This can be done in the process of removing the old finishing floor covering. For this purpose, a large piece of polyethylene film should be laid over the pre-cleaned base. A weight is placed along the edges, while trying to achieve maximum tightness, leaving the middle of the film free. If after a week the inner side of the polyethylene is not covered with condensation, you can safely begin laying the wooden floor underlay. The accumulation of condensation is an indicator of high humidity in the room, you will have to provide the floors with additional waterproofing. Return to the table of contents</a>

Types of plywood.If the floor screed was made according to all the requirements of the technology, the humidity level of the base is not higher than 1% and the issue with thermal insulation and waterproofing is resolved, you can be sure that the finished floor will be dry, warm and will last a long time. Very often, plywood is used as a base for parquet (the best option in this case is FK 4/4). Many specialists prefer to use plywood sheets 1 cm thick for floor repairs; sheets 12 mm thick are also good. In addition to the fact that such material is quite durable, it is also flexible, and this is a very important condition, since plywood sheets take on a very large load. Plywood sheets consist of many layers, high humidity levels are contraindicated for them, otherwise they will begin to delaminate over time. That is why, before you start repairing floors with plywood, check the humidity of the concrete floors. This can be done in the process of removing the old finishing floor covering. For this purpose, a large piece of polyethylene film should be laid over the pre-cleaned base. A weight is placed along the edges, while trying to achieve maximum tightness, leaving the middle of the film free. If after a week the inner side of the polyethylene is not covered with condensation, you can safely begin laying the wooden floor underlay. The accumulation of condensation is an indicator of high humidity in the room, you will have to provide the floors with additional waterproofing. Return to the table of contents</a>

Stage of laying plywood sheets

Laying plywood on a concrete floor. Floor repairs using plywood are performed using materials and tools such as:

Laying plywood on a concrete floor. Floor repairs using plywood are performed using materials and tools such as:

- sheets of plywood;

- soil composition (Primer);

- glutinous composition;

- mastic;

- dowels;

- self-tapping screws;

- Brush (for applying Primer);

- marker;

- a hammer;

- Sander;

- drill;

- screwdriver.

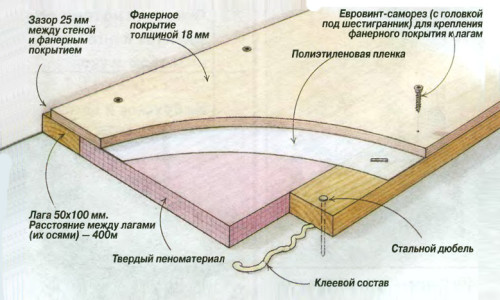

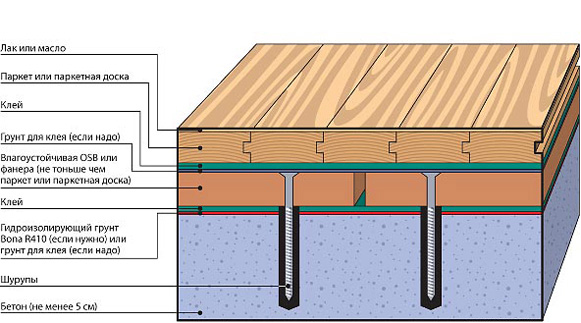

Before performing floor repairs, plywood sheetsit is necessary to cut. For this, the room is measured in advance. When cutting the material, keep in mind that a gap of 1 cm should be left between each sheet of plywood (the gap between the sheet and the wall surface should be 2 cm). Make sure that the material does not touch the wall. Laying the plywood taking into account the required distance will prevent the finished floor from "swelling", which can occur due to a change in size due to temperature changes and increased humidity. It should also be noted that due to the use of small-sized blanks, the floors will be more stable and reliable. Having completed the stage of cutting the material, make sure that the plywood has not begun to delaminate in the places of sawing, since such blanks are not suitable for use in floor repair. Then you can start laying the sheets, while avoiding a single joint of four sheets at once. The technology of laying the material when repairing floors is carried out similar to laying bricks (with a slight shift). After fitting each sheet of plywood, number each individual element. On the base, draw a diagram of how the sheets will be arranged, then put all the blanks aside. Next, the floors must be carefully prepared, removing any remaining building material - mortar, paint, etc. Using a powerful vacuum cleaner, get rid of small debris and dust. Wetting the floors with water is not allowed under any circumstances, as this will damage the wood material. Scheme of floor leveling with moisture-resistant plywood.After the base has been cleared of all unnecessary things, you can start applying the primer (primer composition). The composition of this material is similar to the composition used to glue plywood. The primer copes with several tasks at once: by thoroughly impregnating the base, capturing every remaining microscopic speck of dust, it helps strengthen the surface and creates ideal conditions for good adhesion with other materials. This method of dust removal allows you to significantly enhance the adhesion of plywood sheets and adhesive composition. In addition, with the help of the Primer, the concrete surface is strengthened, its destruction and peeling are prevented, accordingly, dust will no longer form. If the floor repair is to be carried out in a large room, the primer composition, as well as laying plywood sheets, should be applied in certain parts. You can cover the base of a small room with Primer in one stage. As you understand, the primer should be applied shortly before laying the plywood sheets. Please note that walking on the treated base is contraindicated. Return to Contents</a>

Scheme of floor leveling with moisture-resistant plywood.After the base has been cleared of all unnecessary things, you can start applying the primer (primer composition). The composition of this material is similar to the composition used to glue plywood. The primer copes with several tasks at once: by thoroughly impregnating the base, capturing every remaining microscopic speck of dust, it helps strengthen the surface and creates ideal conditions for good adhesion with other materials. This method of dust removal allows you to significantly enhance the adhesion of plywood sheets and adhesive composition. In addition, with the help of the Primer, the concrete surface is strengthened, its destruction and peeling are prevented, accordingly, dust will no longer form. If the floor repair is to be carried out in a large room, the primer composition, as well as laying plywood sheets, should be applied in certain parts. You can cover the base of a small room with Primer in one stage. As you understand, the primer should be applied shortly before laying the plywood sheets. Please note that walking on the treated base is contraindicated. Return to Contents</a>

Stage of plywood laying by own hands

Over the base treated with PrimerUsing a notched trowel, apply the pre-selected mastic. The layer of material should be as thick as recommended on the packaging. Most manufacturers warn that the layer should not exceed 2 cm. A sheet of plywood should be laid on top of the mastic. Self-tapping screws with plastic dowels are used to secure it. The sheets must be secured around the perimeter and diagonally. Dowels are installed at intervals of 20 cm, leaving 2 cm at the edges. Self-tapping screws should be selected so that their length is three times the thickness of the plywood. Fastening of the blanks must be done with extreme caution, since hammer blows can split them. In order to avoid such unpleasant consequences, the base together with the sheet should be drilled using a drill with a diameter that should match the dowel; for further actions, a drill with a larger diameter is used. In such holes, it is enough to simply hide the self-tapping screws together with the caps. After the plywood floor repair has come to an end, it remains to complete the stage of preparing the surface for laying the parquet. Preparatory work includes grinding, for which it is recommended to use a specially designed grinding machine. It is very important to achieve absolute smoothness of the surface, which will not have such defects as burrs, chips, differences in height in the area of the seams and roughness.</ ul>