The chair is represented as a piece of furniture,which will help you relax, rest your soul and body. Its soft base is pleasantly calming, and natural materials evoke pleasant feelings. This piece of furniture can be purchased in a store that offers a large number of chairs made of rattan, wood, and cane. Not everyone has a rocking chair. For its manufacture, you can use plywood as an elastic, pleasant, and environmentally friendly material. Such products are not cheap, but they are worthy competitors to the usual and not entirely safe fiberboard material. Sketches of a chair for cutting out of plywood.allows you to save money significantly, since you only have to spend money on purchasing materials. In addition, installation is not difficult. Such a piece of furniture can easily decorate any room, especially summer cottages and country houses. Possible flaws are easily hidden with fabric decoration and painting.

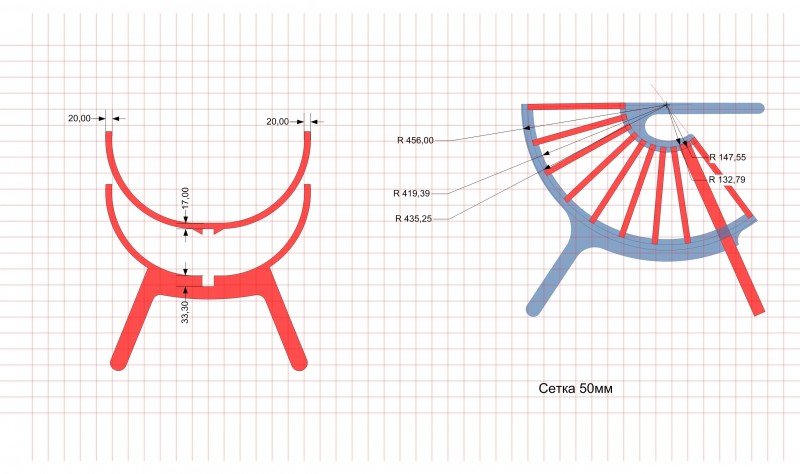

Sketches of a chair for cutting out of plywood.allows you to save money significantly, since you only have to spend money on purchasing materials. In addition, installation is not difficult. Such a piece of furniture can easily decorate any room, especially summer cottages and country houses. Possible flaws are easily hidden with fabric decoration and painting.

How to start manufacturing

Detailed drawing of a plywood chair. To make a chair, it is important to prepare the following tools and materials:

Detailed drawing of a plywood chair. To make a chair, it is important to prepare the following tools and materials:

- plywood with a thickness of 15-20 mm;

- emery cloth;

- electric drill;

- electric jigsaw;

- Screws;

- thin nails with wide hats;

- metal rims;

- joiner glue;

- foam rubber (8 cm);

- artificial leather;

- gloss black paint;

- stain;

- roulette;

- painting tape;

- pencil.

Before you start usingof a certain material, it is necessary to pre-treat the surface with special means. This will protect the base from the effects of external factors. This implies that the rocking chair will be outdoors. The finished product can be placed under a canopy on a summer terrace, in a gazebo, on the porch of a mansion, in a barbecue area, in a meadow, by the pool. Return to contents</a>

Calculation of materials and production of a template

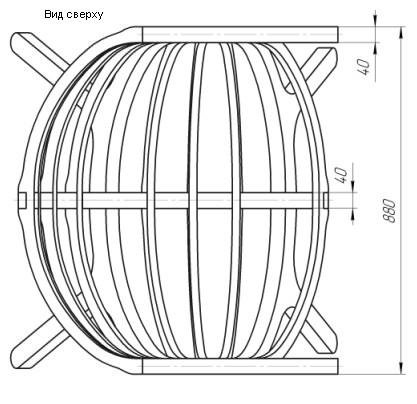

Chair made of plywood sheet: top view with dimensions.Birch plywood is used as a material for making the chair. Its thickness will be 4, 10 and 15 mm. Tools and basic woodworking skills will be useful for the work. It is important to note that the supports and side parts are finished with plywood from 15 mm thick, while 10 mm material is needed to install the back and seat. Before carrying out the main activities, it is necessary to make a detailed drawing. You can draw it yourself or use help. The initial stage of the work will be the preparation of templates from paper or cardboard. They are made in real scale. The outlines of these blanks are transferred to the prepared plywood. Later, the necessary parts are cut out from these patterns. These parts are cleaned, sanded with sandpaper of varying density. Priming of the parts and their painting should be carried out in disassembled form. However, before carrying out such work, you need to check the conformity of the sizes, assemble the chair. Possible defects can be corrected.

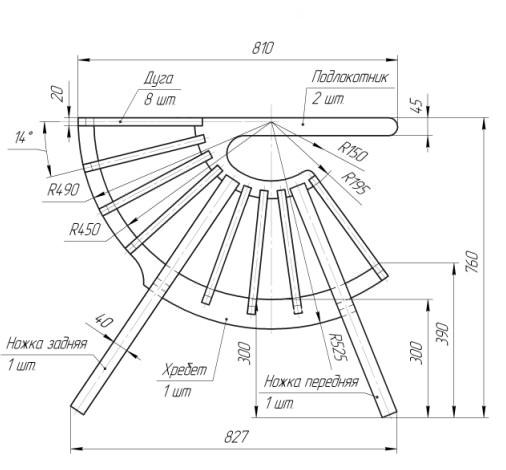

Chair made of plywood sheet: top view with dimensions.Birch plywood is used as a material for making the chair. Its thickness will be 4, 10 and 15 mm. Tools and basic woodworking skills will be useful for the work. It is important to note that the supports and side parts are finished with plywood from 15 mm thick, while 10 mm material is needed to install the back and seat. Before carrying out the main activities, it is necessary to make a detailed drawing. You can draw it yourself or use help. The initial stage of the work will be the preparation of templates from paper or cardboard. They are made in real scale. The outlines of these blanks are transferred to the prepared plywood. Later, the necessary parts are cut out from these patterns. These parts are cleaned, sanded with sandpaper of varying density. Priming of the parts and their painting should be carried out in disassembled form. However, before carrying out such work, you need to check the conformity of the sizes, assemble the chair. Possible defects can be corrected. Drawing of front legs for a plywood chair.To make a plywood chair, the traditional scheme is most often used, which has side parts shaped like a banana or boomerang, and crossbars. Before starting work, you should cut out a cardboard base, a kind of template. The side elements, support strips will be mounted from plywood 15-20 mm thick. The most important parts of the entire structure will be the sidewalls. There are some difficulties with their measurement, because they have a non-standard shape and unstable width. Therefore, when starting to draw a template, you will have to draw blindly. You should decide on the dimensions, bending angle and tilt of the upcoming sample. To ensure the most comfortable conditions, you can apply the drawing to any hard material. This will help to check the presence of the correct tilt angle. Such a sample is easily placed on the floor and sways. When choosing the dimensions of the crossbars, you can make them 60 cm long and 7 cm wide, as is often the case. The supporting beams are assembled from plywood 20 mm thick and 5-7 cm long. Return to contents</a>

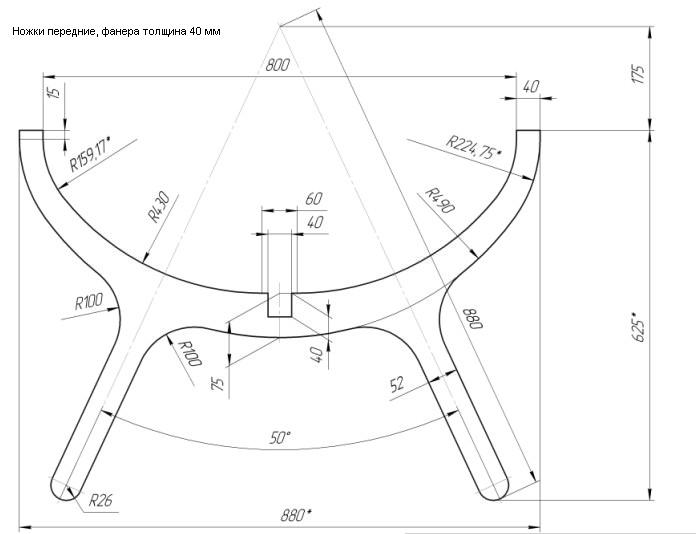

Drawing of front legs for a plywood chair.To make a plywood chair, the traditional scheme is most often used, which has side parts shaped like a banana or boomerang, and crossbars. Before starting work, you should cut out a cardboard base, a kind of template. The side elements, support strips will be mounted from plywood 15-20 mm thick. The most important parts of the entire structure will be the sidewalls. There are some difficulties with their measurement, because they have a non-standard shape and unstable width. Therefore, when starting to draw a template, you will have to draw blindly. You should decide on the dimensions, bending angle and tilt of the upcoming sample. To ensure the most comfortable conditions, you can apply the drawing to any hard material. This will help to check the presence of the correct tilt angle. Such a sample is easily placed on the floor and sways. When choosing the dimensions of the crossbars, you can make them 60 cm long and 7 cm wide, as is often the case. The supporting beams are assembled from plywood 20 mm thick and 5-7 cm long. Return to contents</a>

Wood processing: nuances

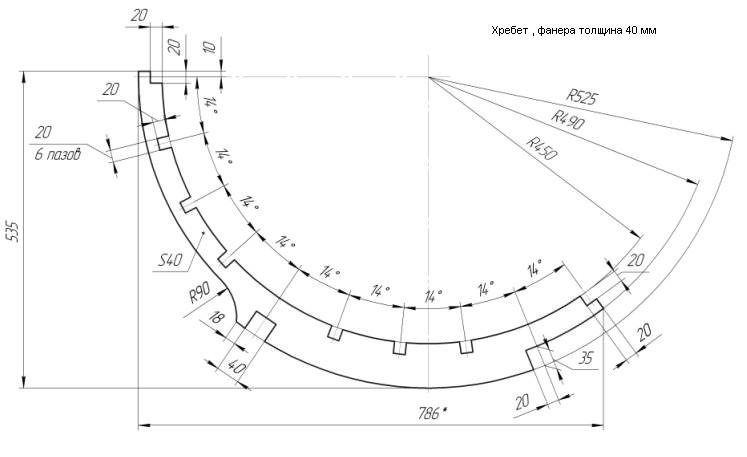

Drawing of the “spine” element for a plywood chair.The plywood surface should be prepared for work. To do this, you can use a high-quality grinding machine. It will not be difficult to clean the surface layer and remove chamfers. Particular attention should be paid to the end parts. A high-quality grinding machine will help to sand the surfaces and remove small chamfers in a short time. Considering the dampness outside, special attention should be paid to the end parts. To do this, they need to be soaked in heated drying oil and slightly flatten the fibers with a hammer. This technique will help to avoid excessive moisture absorption. Return to contents</a>

Drawing of the “spine” element for a plywood chair.The plywood surface should be prepared for work. To do this, you can use a high-quality grinding machine. It will not be difficult to clean the surface layer and remove chamfers. Particular attention should be paid to the end parts. A high-quality grinding machine will help to sand the surfaces and remove small chamfers in a short time. Considering the dampness outside, special attention should be paid to the end parts. To do this, they need to be soaked in heated drying oil and slightly flatten the fibers with a hammer. This technique will help to avoid excessive moisture absorption. Return to contents</a>

Making the frame of the chair

To ensure that the chair is level and correct,you should take the previously prepared template and place it on the plywood. After that, you can trace it with a pencil. Then, the sample is cut out with an electric jigsaw. Plywood consumption for a similar chair:1 sheet measuring 1250x2500 mm. The other side part is made in a similar way. Both parts must be absolutely identical. After that, the resulting elements are cleaned with sandpaper. Then you can fasten the support bars to the sidewalls. This can be done with wood glue. To ensure that the bars are held as firmly as possible, they can be additionally fixed with screws. The position of the bars should be equal in relation to the side parts. The back of the chair should be fixed on them. It is very important to be precise here, since the slightest irregularity will lead to skewing of the crossbars. To avoid such mistakes, it is necessary to measure this distance with particular scrupulousness. One of the slats should be screwed to the bars of the top row with screws. The other strips are mounted in a similar way. In this way, the frame of the product is made. Return to the table of contents</a>

Plywood consumption for a similar chair:1 sheet measuring 1250x2500 mm. The other side part is made in a similar way. Both parts must be absolutely identical. After that, the resulting elements are cleaned with sandpaper. Then you can fasten the support bars to the sidewalls. This can be done with wood glue. To ensure that the bars are held as firmly as possible, they can be additionally fixed with screws. The position of the bars should be equal in relation to the side parts. The back of the chair should be fixed on them. It is very important to be precise here, since the slightest irregularity will lead to skewing of the crossbars. To avoid such mistakes, it is necessary to measure this distance with particular scrupulousness. One of the slats should be screwed to the bars of the top row with screws. The other strips are mounted in a similar way. In this way, the frame of the product is made. Return to the table of contents</a>

Making out the soft part of the chair

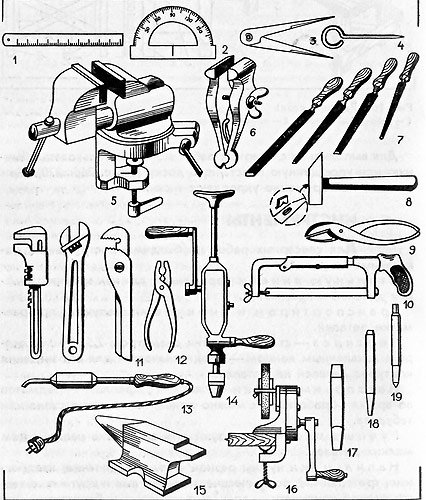

Tools for metalwork:1 - steel ruler; 2 - protractor; 3 - compasses; 4 - scriber; 5 - table vice; 6 - hand vice; 7 - files; 8 - hammer; 9 - hand scissors; 10 - hacksaw; 11 - adjustable wrenches; 12 - pliers; 13 - soldering iron; 14 - hand drill; 15 - table anvil; 16 - table sharpener; 17 - chisel; 18 - punch; 19 - center punch. To make the chair look nice and interesting, it is necessary to cover it with fabric. Do not forget about the plywood parts, which are painted. The side parts can be treated with stain of any tone. To give the surface a deeper shade, go over it with this composition 2 times. The inside of the side panels is painted with black paint with a glossy base. In order to reliably provide and protect unnecessary parts from being painted, you can use special masking tape. The ends of the side panels should be reinforced with metal rims. Their dimensions should correspond to the dimensions of these parts of the chair. They are fixed to the points that will be in contact with the floor surface. The rims are fixed with screws, and the holes must be made with an electric drill. The diameter of the drill should be equal to the size of the screw thread. It is best to close the screw heads with plugs. They are sold in specialized stores in large quantities and in different colors. To give the rocking chair softness, you can make a covering of artificial leather. It will be pleasant to lie down and sit on. The leather substitute can be selected in any color. First, the back of the chair is finished with it. The fabric is fixed to the frame with small nails with voluminous heads. In the back, the upholstery is fixed along the edges of the cross members, in the front it covers the strips at the top and bottom. To make the base as durable as possible, the attachment points should be reinforced with wood glue. The mattress, i.e. the soft part of the chair, is made of 8 cm thick foam rubber. The outer part of the seat can be finished with the same leatherette. Return to contents</a>

Tools for metalwork:1 - steel ruler; 2 - protractor; 3 - compasses; 4 - scriber; 5 - table vice; 6 - hand vice; 7 - files; 8 - hammer; 9 - hand scissors; 10 - hacksaw; 11 - adjustable wrenches; 12 - pliers; 13 - soldering iron; 14 - hand drill; 15 - table anvil; 16 - table sharpener; 17 - chisel; 18 - punch; 19 - center punch. To make the chair look nice and interesting, it is necessary to cover it with fabric. Do not forget about the plywood parts, which are painted. The side parts can be treated with stain of any tone. To give the surface a deeper shade, go over it with this composition 2 times. The inside of the side panels is painted with black paint with a glossy base. In order to reliably provide and protect unnecessary parts from being painted, you can use special masking tape. The ends of the side panels should be reinforced with metal rims. Their dimensions should correspond to the dimensions of these parts of the chair. They are fixed to the points that will be in contact with the floor surface. The rims are fixed with screws, and the holes must be made with an electric drill. The diameter of the drill should be equal to the size of the screw thread. It is best to close the screw heads with plugs. They are sold in specialized stores in large quantities and in different colors. To give the rocking chair softness, you can make a covering of artificial leather. It will be pleasant to lie down and sit on. The leather substitute can be selected in any color. First, the back of the chair is finished with it. The fabric is fixed to the frame with small nails with voluminous heads. In the back, the upholstery is fixed along the edges of the cross members, in the front it covers the strips at the top and bottom. To make the base as durable as possible, the attachment points should be reinforced with wood glue. The mattress, i.e. the soft part of the chair, is made of 8 cm thick foam rubber. The outer part of the seat can be finished with the same leatherette. Return to contents</a>

Important points

To ensure maximum comfort,You can make a removable seat cover. Such an item will be fixed to the frame and have a soft foam shell. Externally, the mattress can be decorated at your discretion. You can make a mosaic pattern or applique. Any materials can be used. The main condition will be the general compliance with the appearance of the room. A self-made chair will give a lot of positive emotions and help you rest and relax. Speaking about the design of the entire chair, you can choose any variations that match the preferences of the master. So, the side parts can be painted brown, the slats can be treated with stain or completely abandon it. The surface can be impregnated with furniture varnish. Before carrying out such work, it is necessary to sand the surface. As an analogue of the chair, you can make a sofa of a similar sample. It will have a wider base.</ ul>