Do-it-yourself floor soundproofing -an event that allows you to protect yourself from noise. One of the important components of comfort in the house is silence. Naturally, every person wants to feel silence, peace, a calm atmosphere for rest in the house. Coming home from a noisy street, having spent the whole day talking or arguing with colleagues, having spent a huge amount of time in traffic jams, in queues, in sorting out relationships with loved ones, friends or even strangers, you want to feel a pleasant warmth, to be sure that no one will disturb you, no sound or rumble will disturb your sleep, dinner, or just rest on the couch. To achieve this, you should take care of the soundproofing of not only the walls, windows, ceiling, but also the floor. Floor diagram with sound insulation layer.It should be taken into account that over time, physical wear and tear occurs on the floor, so even light movement on such a floor can cause unpleasant noises. This means that soundproofing of the floor must be done wisely, using high-quality material that will last long enough and will not cause any problems in the future in terms of peace and comfort.

Floor diagram with sound insulation layer.It should be taken into account that over time, physical wear and tear occurs on the floor, so even light movement on such a floor can cause unpleasant noises. This means that soundproofing of the floor must be done wisely, using high-quality material that will last long enough and will not cause any problems in the future in terms of peace and comfort.

Sound insulation of the floor: order and features

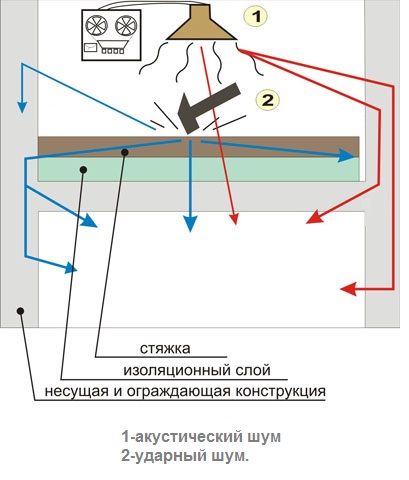

Acoustic and impact penetration diagramnoise. Soundproofing a floor consists of several well-thought-out steps that do not allow any mistakes that will later make themselves known. A person must be very patient, take his time, think everything through down to the smallest detail. Often, specialists in this field are guided by such a concept as soundproofing a floor using a floating floor. This name was invented as a result of some features that allow the selected material not to touch the walls. If this condition is not met, then a space may appear between the wall itself and the floor covering, which will subsequently lead to noise. Therefore, it is necessary to adhere to the principle of a floating floor in order to know how to properly soundproof. The most common and acceptable method is soundproofing the floor under the laminate. The principle of a floating floor is used by almost everyone, as it is characterized by a number of positive aspects:

Acoustic and impact penetration diagramnoise. Soundproofing a floor consists of several well-thought-out steps that do not allow any mistakes that will later make themselves known. A person must be very patient, take his time, think everything through down to the smallest detail. Often, specialists in this field are guided by such a concept as soundproofing a floor using a floating floor. This name was invented as a result of some features that allow the selected material not to touch the walls. If this condition is not met, then a space may appear between the wall itself and the floor covering, which will subsequently lead to noise. Therefore, it is necessary to adhere to the principle of a floating floor in order to know how to properly soundproof. The most common and acceptable method is soundproofing the floor under the laminate. The principle of a floating floor is used by almost everyone, as it is characterized by a number of positive aspects:

- The finished floor is devoid of any mechanical fasteners that are capable of transmitting noise and sounds;

- has high sound insulation properties;

- simple installation technology that does not require special or narrow knowledge from the master;

- it is only necessary to follow the principle of systematic load distribution;

- characterized by economy and availability of materials.

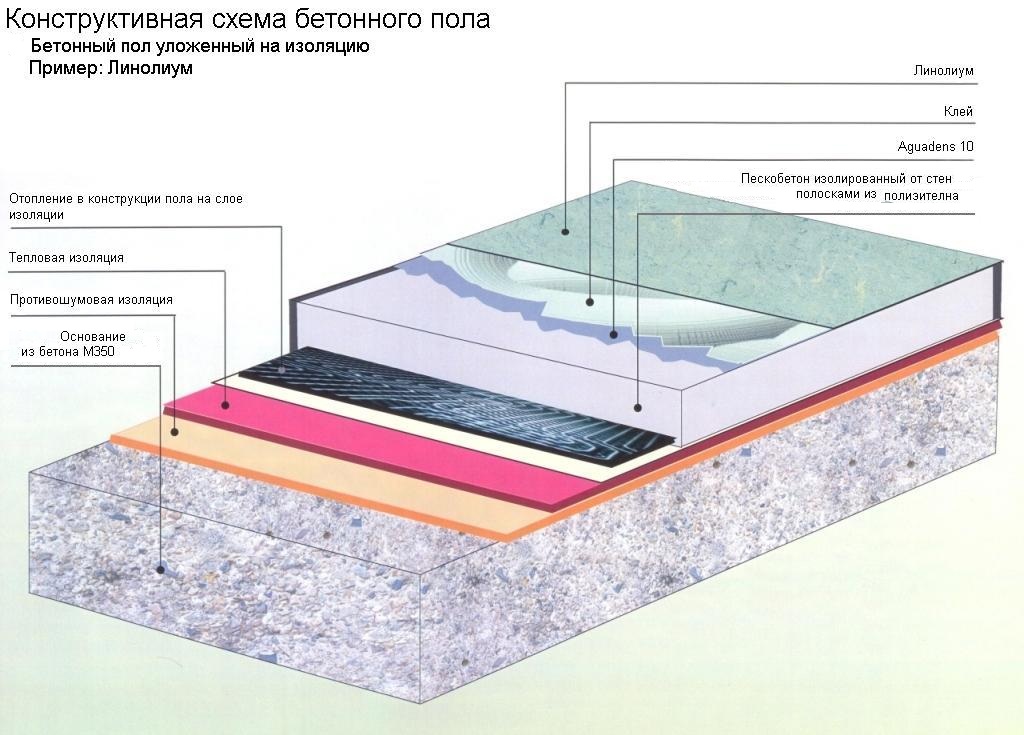

Return to Contents</a>Soundproofing features Soundproofing scheme for reinforced screed.In order to know how to soundproof a floor correctly and avoid mistakes, you should take into account some of the process features. Soundproofing a floor is possible if you rely on the use of only certain subfloor slabs. When laying them, the master must take into account the possibility of creating a gap of 10 mm between the wall and the edge of the tile being laid. As noted above, one of the advantages of a floating floor under the laminate is the simple installation technology. Before starting the installation process itself, that is, soundproofing the floor, you should first get rid of the old coating. After all, the base under the laminate should be extremely smooth, dry, without any roughness. If there are holes, depressions, indentations, unevenness, they are eliminated using a leveling mixture. In this case, it is necessary to take into account that the layer of the leveling mixture does not exceed 2 mm. As soon as this condition is met, proceed to the next stage of the work. It consists of priming the floor surface. In order to determine whether there is a difference in height, they resort to checking it with a building level. It is generally accepted that the existing discrepancy can reach 10 mm, no more. Then they proceed to making a screed of sand and concrete, separated from the walls with the help of vibration-absorbing materials - we are talking about glass or basalt wool, foamed polymers, etc. Here the choice is up to the master himself.

Soundproofing scheme for reinforced screed.In order to know how to soundproof a floor correctly and avoid mistakes, you should take into account some of the process features. Soundproofing a floor is possible if you rely on the use of only certain subfloor slabs. When laying them, the master must take into account the possibility of creating a gap of 10 mm between the wall and the edge of the tile being laid. As noted above, one of the advantages of a floating floor under the laminate is the simple installation technology. Before starting the installation process itself, that is, soundproofing the floor, you should first get rid of the old coating. After all, the base under the laminate should be extremely smooth, dry, without any roughness. If there are holes, depressions, indentations, unevenness, they are eliminated using a leveling mixture. In this case, it is necessary to take into account that the layer of the leveling mixture does not exceed 2 mm. As soon as this condition is met, proceed to the next stage of the work. It consists of priming the floor surface. In order to determine whether there is a difference in height, they resort to checking it with a building level. It is generally accepted that the existing discrepancy can reach 10 mm, no more. Then they proceed to making a screed of sand and concrete, separated from the walls with the help of vibration-absorbing materials - we are talking about glass or basalt wool, foamed polymers, etc. Here the choice is up to the master himself. Comparison of sound absorption of foam andspecial materials. It is not difficult to soundproof the floor, to choose the sequence of the work to be performed, since the principle is the same, it does not depend on whether the soundproofing of the floor is carried out under the laminate or any other floor covering. The whole point of the work is to prevent the presence of acoustic bridges as much as possible, they reduce the effectiveness of the work done. To eliminate this possible defect, the flooring must be isolated from the partition and wall using temporary formwork. It is removed immediately after the concrete screed has completely hardened. The height of the concrete screed in question must exceed the thickness of the sound insulator and the floating floor. Specially selected material, in this case laminate, is carefully laid on the surface, pre-prepared, while the joints are subject to careful gluing. The resulting insulator layer should be applied slightly above the screed, naturally, along the entire perimeter. If excess is formed after the overlay, it is subsequently removed, or rather, cut off. Before the procedure of installing the screed, a polyethylene film is placed over the sound insulator, the edges of which are glued to the formwork using construction tape.

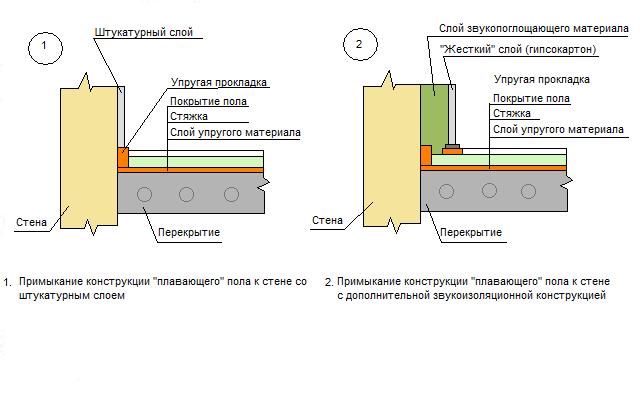

Comparison of sound absorption of foam andspecial materials. It is not difficult to soundproof the floor, to choose the sequence of the work to be performed, since the principle is the same, it does not depend on whether the soundproofing of the floor is carried out under the laminate or any other floor covering. The whole point of the work is to prevent the presence of acoustic bridges as much as possible, they reduce the effectiveness of the work done. To eliminate this possible defect, the flooring must be isolated from the partition and wall using temporary formwork. It is removed immediately after the concrete screed has completely hardened. The height of the concrete screed in question must exceed the thickness of the sound insulator and the floating floor. Specially selected material, in this case laminate, is carefully laid on the surface, pre-prepared, while the joints are subject to careful gluing. The resulting insulator layer should be applied slightly above the screed, naturally, along the entire perimeter. If excess is formed after the overlay, it is subsequently removed, or rather, cut off. Before the procedure of installing the screed, a polyethylene film is placed over the sound insulator, the edges of which are glued to the formwork using construction tape. Types of joining a floating floor towall The soundproofing surface is applied on top with beacons, the height of which should be 15 mm (a similar beacon can be made of plasterboard). A reinforced mesh is laid on top of these beacons, which is filled with cement mortar 35-40 mm thick. The surface must be leveled and grouted. To achieve final strength, it is necessary to mix a certain amount of basalt or polypropylene fiber additives into the cement mixture. The calculation is as follows: 1 kg / m³. The screed must dry thoroughly. In summer, this happens by itself, but in winter, electrical appliances are connected, drying the screed as much as possible. As soon as the screed dries, they begin laying the final coating, that is, the laminate. Return to the table of contents</a>

Types of joining a floating floor towall The soundproofing surface is applied on top with beacons, the height of which should be 15 mm (a similar beacon can be made of plasterboard). A reinforced mesh is laid on top of these beacons, which is filled with cement mortar 35-40 mm thick. The surface must be leveled and grouted. To achieve final strength, it is necessary to mix a certain amount of basalt or polypropylene fiber additives into the cement mixture. The calculation is as follows: 1 kg / m³. The screed must dry thoroughly. In summer, this happens by itself, but in winter, electrical appliances are connected, drying the screed as much as possible. As soon as the screed dries, they begin laying the final coating, that is, the laminate. Return to the table of contents</a>

Features of soundproofing the floor under the screed

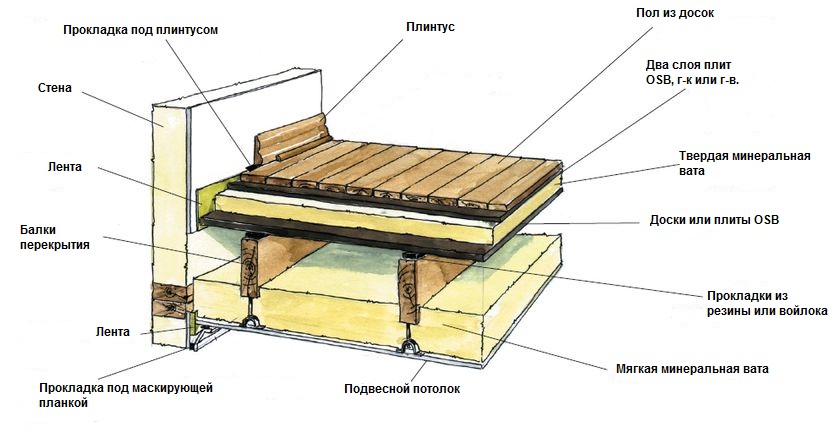

In addition to the considered method of floor screeding under laminate, there is another option, the so-called seamless, or seamless screed. Double floor scheme for improved soundsuppression. Its only drawback is that it takes a long time to dry. Drying time is at least 4 weeks. Therefore, in most cases, they resort to such a method as dry screed. Drying is not required here, and as for the materials, their choice is made in accordance with specific requirements. How is dry screed done? First of all, dry backfill work is carried out, then it is leveled with beacon slats. In order for the backfill to be evenly distributed, gypsum boards or thin chipboards are laid on top of it, then gypsum fiber boards are applied, which are glued with an offset (we are talking about folds). The folds are subject to gluing and fixing with self-tapping screws. Soundproofing of the floor is complete. To provide yourself with complete, absolute soundproofing, it must be comprehensive. This means that one floor screed will not be enough to completely protect yourself from noise. You should protect the walls, ceiling, windows. Only in this case, no noise (street, neighbors, etc.) will force you to give up the comfort and peace of your home.</ ul>

Double floor scheme for improved soundsuppression. Its only drawback is that it takes a long time to dry. Drying time is at least 4 weeks. Therefore, in most cases, they resort to such a method as dry screed. Drying is not required here, and as for the materials, their choice is made in accordance with specific requirements. How is dry screed done? First of all, dry backfill work is carried out, then it is leveled with beacon slats. In order for the backfill to be evenly distributed, gypsum boards or thin chipboards are laid on top of it, then gypsum fiber boards are applied, which are glued with an offset (we are talking about folds). The folds are subject to gluing and fixing with self-tapping screws. Soundproofing of the floor is complete. To provide yourself with complete, absolute soundproofing, it must be comprehensive. This means that one floor screed will not be enough to completely protect yourself from noise. You should protect the walls, ceiling, windows. Only in this case, no noise (street, neighbors, etc.) will force you to give up the comfort and peace of your home.</ ul>