Any person, regardless of the place of hisyou want to rest in peace and quiet. Extraneous sounds negatively affect the nervous system, irritate and excite it. Fenced off from extraneous noise coming from neighbors, you can stay healthy and peace of mind for a long time. Wanting to build in your home a reliable protection against external vibrations, most owners are wondering how to make noise insulation of the floor. The answer to it can be obtained below.  Preparation of the floor for soundproofing. Modern construction industry has an extensive set of insulation materials, which will allow to establish comfort and balance in the room. All sounds coming into the rooms can be divided into these types:

Preparation of the floor for soundproofing. Modern construction industry has an extensive set of insulation materials, which will allow to establish comfort and balance in the room. All sounds coming into the rooms can be divided into these types:

Actions to get rid of the listedextraneous stimuli, it is customary to call noise insulation of the floor. Despite the considerable thickness and power of concrete slabs, extraneous sounds from neighbors nevertheless penetrate into the room. Striking vibrations are particularly clearly pronounced. Putting any insulating material, you can achieve better results. To understand how to make noise insulation correctly, you should study the properties of the proposed modern materials. They allow you to do the work as quickly as possible, without seeking help from specialists.

Screed as a traditional insulator

Scheme of floor screed device. This type of soundproofing is referred to the standard ways of protecting against extraneous noise. Its cost is low. To create the best quality layer, it is not enough to increase its thickness. Dimensions do not affect the quality of the structure absorbing noise. Deficiencies of such a device are the following:

Scheme of floor screed device. This type of soundproofing is referred to the standard ways of protecting against extraneous noise. Its cost is low. To create the best quality layer, it is not enough to increase its thickness. Dimensions do not affect the quality of the structure absorbing noise. Deficiencies of such a device are the following:

To qualitatively carry out the isolation of the floor with itshands, it is necessary to organize a screed with an additional noise-insulating layer. By giving preference to one or another material, one should study its positive and negative aspects. The soundproofing layer on the floor is laid out using the following materials:

- mineral wool (basalt);

- cork cover;

- polystyrene or expanded polystyrene;

- expanded polypropylene and polyethylene foam;

- expanded clay.

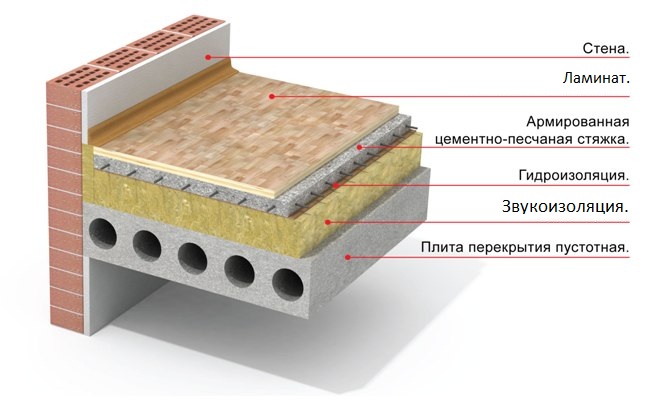

Sound insulation technology of the floor "installation for concrete." To make noise insulation of a floor it is possible by means of mineral cotton wool. She perfectly copes with the tasks assigned to her and does not have a harmful effect on a person. Such raw materials are actively used not only for the floor, but also for the processing of partitions. It well keeps the room warm and protects against the penetration of extraneous noise. Due to the fact that mineral wool does not tolerate dampness, as a result of contact with which the desired properties are reduced, it needs good waterproofing. About its laying should take care beforehand. Expanded polystyrene requires installation of a vapor barrier layer, which provides optimal protection in damp areas. Otherwise, fungus and mold may appear. A defect of this raw material is the evaporation of harmful substances and the ability to maintain combustion. Taking into account the cork coating, it is worth noting its weak properties with respect to sound absorption, it better realizes its qualities in the field of thermal insulation. Floor insulation is made with the help of the following devices:

Sound insulation technology of the floor "installation for concrete." To make noise insulation of a floor it is possible by means of mineral cotton wool. She perfectly copes with the tasks assigned to her and does not have a harmful effect on a person. Such raw materials are actively used not only for the floor, but also for the processing of partitions. It well keeps the room warm and protects against the penetration of extraneous noise. Due to the fact that mineral wool does not tolerate dampness, as a result of contact with which the desired properties are reduced, it needs good waterproofing. About its laying should take care beforehand. Expanded polystyrene requires installation of a vapor barrier layer, which provides optimal protection in damp areas. Otherwise, fungus and mold may appear. A defect of this raw material is the evaporation of harmful substances and the ability to maintain combustion. Taking into account the cork coating, it is worth noting its weak properties with respect to sound absorption, it better realizes its qualities in the field of thermal insulation. Floor insulation is made with the help of the following devices:

- level;

- pencil;

- stationery knife;

- brush;

- putty knife;

- roulette, marker;

- Drill with a set of drills and screws;

- glue;

Traditionally in an apartment for making tiesapply cement grade 150 and 200. It provides a small load on the surface, while maintaining excellent protection against extraneous noise. The solution for such a coating is prepared as follows: the prepared dry cement composition is mixed with the sand mixture in a proportion of 1: 3. Then, with the help of beacons, the installation is carried out in one coating. Back to contents</a>

Floor insulation with cement screed

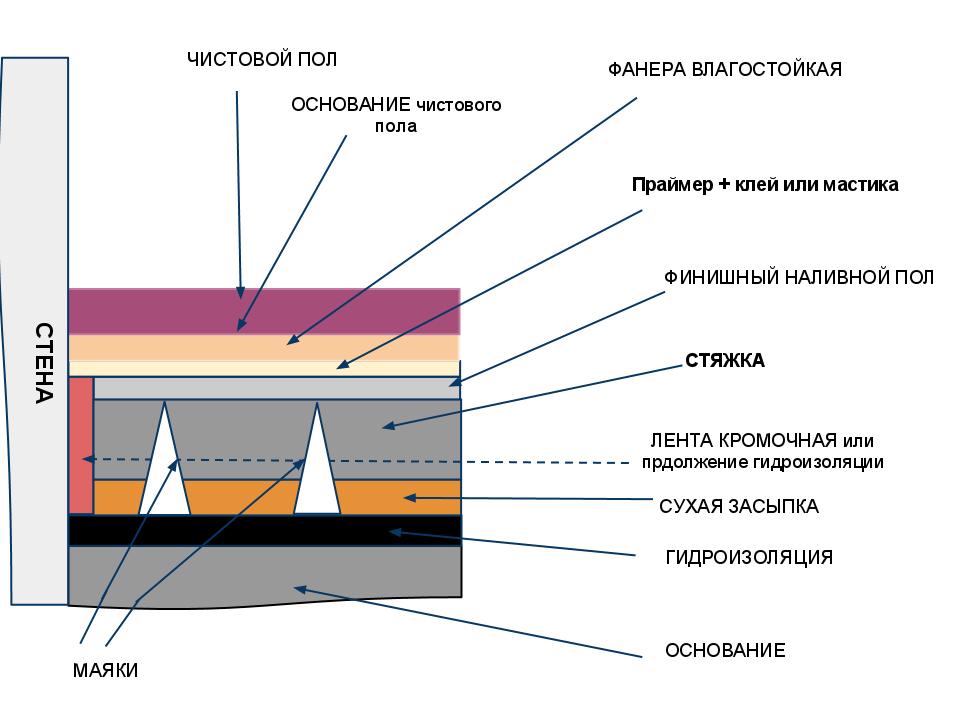

Scheme of cement-sand screed floors. Such a coating is done in the following way:

Scheme of cement-sand screed floors. Such a coating is done in the following way:

Back to contents</a>

Sound insulation of wooden floors: rules

Sound insulation of wooden floors. To perform noise insulation of a wooden floor with their own hands, a dry screed is used. The materials used are different options depending on the query. Traditionally, a simplified version of the finish is applied:

Sound insulation of wooden floors. To perform noise insulation of a wooden floor with their own hands, a dry screed is used. The materials used are different options depending on the query. Traditionally, a simplified version of the finish is applied:

At the time of fixing the floor skirting boards it is not recommended to drive the nails into the floor or walls, which can disrupt the sound insulation of the cover. Back to contents</a>

Installation of a soundproof layer on a wooden covering

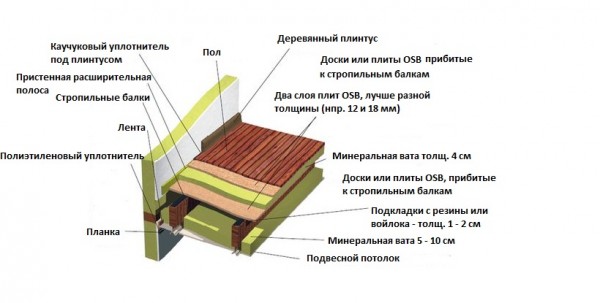

Soundproofing floor with woodenlags. To understand how to make noise insulation in this way, it is necessary to prepare an appropriate insulation material. In this way, the room can be protected from air and mechanical vibrations. A good option is the use of mineral wool. The protection against air noise can be done in this way:

Soundproofing floor with woodenlags. To understand how to make noise insulation in this way, it is necessary to prepare an appropriate insulation material. In this way, the room can be protected from air and mechanical vibrations. A good option is the use of mineral wool. The protection against air noise can be done in this way:

Calculate the distance between these elements can be, taking into account the following factors:

- strength of the foundation. A too thin coating of the surface provides a basis for reducing the distance between the lags. Acceptable indicators are 40-60 cm;

- width of the thermal insulation material. A qualitative level of protection against extraneous noise can be achieved by reducing the gaps between the selected raw materials.

The lumens appearing in the space between the mineral wool layers and lags are easily sealed with a mounting foam. So you can organize a stable and airtight coating.

The wood used must be treated with any antiseptic that will protect its surface from the destructive effect of moisture.

Back to contents</a>

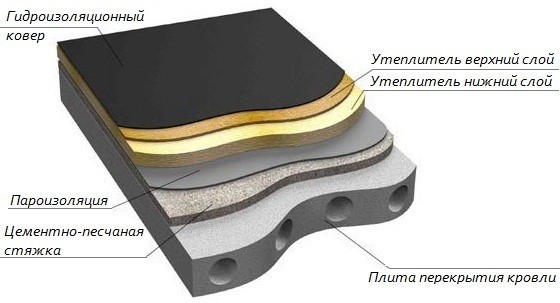

Soundproofing for concrete screed: nuances

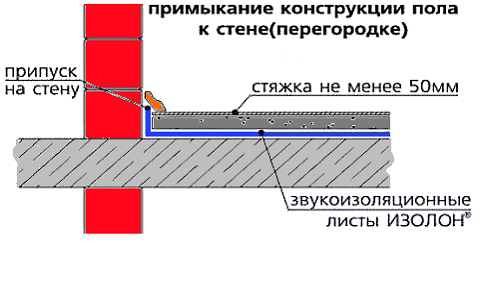

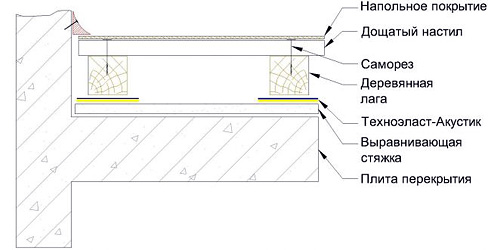

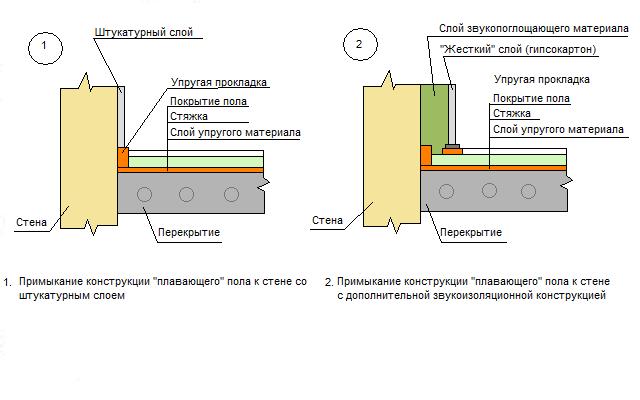

The scheme of the device "floating" floor. This kind of work will be somewhat difficult, in contrast to the organization of a conventional floor screed. What is needed for this?

The scheme of the device "floating" floor. This kind of work will be somewhat difficult, in contrast to the organization of a conventional floor screed. What is needed for this?

So, the ways of carrying out the abovenoise insulation will allow to perform the work in an organized and correct manner. Having mastered this technique, it is possible to carry out similar coatings on the balcony, veranda and other premises. Carrying out similar works, it is not necessary to save on materials, because pleasant microclimate, silence and tranquility are most important.