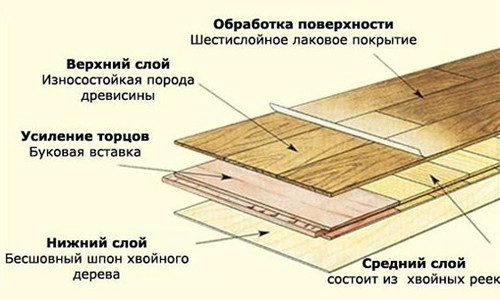

It would seem that thanks to its impressive sizeparquet board, its installation is much simpler than parquet or laminate. This is not entirely true. This material, which has a pronounced layered structure, can easily fail even with minor violations of the technology of its installation. It is necessary to take into account the fact that this process is not simple, there are plenty of subtleties and nuances in it. Before starting independent work, you should not only thoroughly study the instructions for laying parquet boards from the manufacturer, but also take into account the experience and advice of those who have professionally mastered this process. Parquet board diagram.

Parquet board diagram.

What is a parquet board

Externally, it resembles laminate: the same oblong panel. Its standard sizes are:

- length 1,8-2,4 m;

- width 14-20 cm;

- thickness 10-24 mm.

The distinctive feature of dividing parquet boards into groups is the structure of the base:

Figure 1. Types of parquet boards. Another distinctive feature is the number of planks:

Figure 1. Types of parquet boards. Another distinctive feature is the number of planks:

This is a natural finishing material.The outer layer is made of valuable and coniferous wood. The front side is usually covered with transparent parquet varnish. Before starting work, you should stock up on the necessary tools:

- a saw with fine teeth;

- square, measuring tape, ruler and pencil;

- hammer and bar for padding;

- a drill and drills;

- wedges and staples.

Figure 2.Methods of laying parquet boards: 2a - ultralock, 2b - kombilok. Certain conditions must be maintained in the room where the flooring is being laid: humidity 40-60% and temperature 18-22 ºС. If the flooring is being laid on a heated floor, its temperature should be reduced to 18-20 ºС a day or two before the start of work. It can be increased to the usual values (but not higher than 28 ºС) two days after the end of the work. Wood changes its dimensions significantly with changes in humidity, so a gap of about 1 cm must be left between the flooring and the walls. Wedges provide reliability to the flooring. There must also be gaps around the pipes. The finishing material must be kept in the room where it is to be laid for at least two days. It must remain in the packaging during this time. Return to contents</a>

Figure 2.Methods of laying parquet boards: 2a - ultralock, 2b - kombilok. Certain conditions must be maintained in the room where the flooring is being laid: humidity 40-60% and temperature 18-22 ºС. If the flooring is being laid on a heated floor, its temperature should be reduced to 18-20 ºС a day or two before the start of work. It can be increased to the usual values (but not higher than 28 ºС) two days after the end of the work. Wood changes its dimensions significantly with changes in humidity, so a gap of about 1 cm must be left between the flooring and the walls. Wedges provide reliability to the flooring. There must also be gaps around the pipes. The finishing material must be kept in the room where it is to be laid for at least two days. It must remain in the packaging during this time. Return to contents</a>

Floating way of laying

The most popular method for indoor areaswhich does not exceed 60 m2. This technology of laying parquet boards implies that the floor base is well prepared, and the board has a good and reliable lock (see Fig. 2). There are several types of locking joints, but the two most common are:

- an ultralok (Figure 2a);

- combinations (Fig. 2b).

Most specialists prefer the combination of combinatorial connectors. It is more convenient for assembly and more reliable in terms of breaking. Return to contents</a>Preparing the base surface for laying Figure 3. Technology of laying parquet boards.To install this way, you need a strong, very even and dry base. These properties are typical for concrete screeds and adjustable wooden floors. Both options have their pros and cons:

Figure 3. Technology of laying parquet boards.To install this way, you need a strong, very even and dry base. These properties are typical for concrete screeds and adjustable wooden floors. Both options have their pros and cons:

- The screed can be thin, which is especially important for low spaces;

- You can lay communications under the adjustable floors, but the height of the room decreases slightly.

Parquet flooring on an uneven base willannoyingly creak, so the alignment control must be thorough, it is done with a long construction or water level. It is better to make a screed on the basis of self-leveling mixtures. After laying and leveling, you need to give it about three weeks of aging to gain strength and dry completely. The base of the adjustable floor is a durable plate of moisture-resistant plywood, into which adjustable threaded legs are screwed. They can be used to adjust the ideal horizontality. A quick, convenient and reliable method. Another plus: you can lead on such a base in any way. To protect the parquet flooring from moisture, a synthetic, composite or natural cork backing is necessarily laid under it. Its thickness should not be more than 2-3 mm. To seal the seams between the sheets of the backing, special tape is used. Return to the table of contents</a>The order and technology of laying Figure 4.Methods of laying parquet boards: 4a - glue, 4b - at an angle, 4c - laying on a wooden base, 4d - laying on joists. The first row of panels is laid with the left side of the lock (see Fig. 2) to the wall with a gap of about 1 cm and secured with wedges. The direction is taken along the daylight falling from the window. Each new row usually begins with the remainder of the previous one, if it is not less than 0.5 m. It is necessary to ensure that dirt and sand do not get into the locking joint. A wooden block can be used to finish off the joined boards. If desired, the locking joints of the boards can be glued. This is done not to fix the joints, but to protect against water spilled on the floor. To make the pipe outline, apply a board to them, make markings (see Fig. 3a and 3b), drill holes 2 cm larger than the pipe diameter and saw off the edge of the board (see Fig. 3c). Then put the board in place and glue the sawn segment (see Fig. 3d). The edge of the hole can be covered with a suitable ring. The boards of the last row are cut to the required width taking into account the expansion gap, the locking edge is cut off from the groove of the boards of the penultimate row, and glue is applied to the groove. After this, the boards are carefully put in place using a stop bracket. Expansion wedges are installed in the expansion gap. After laying is complete, the wedges are removed from the expansion gap along the entire perimeter of the floor and the baseboard is installed. The baseboard is attached only to the wall. Return to Contents</a>

Figure 4.Methods of laying parquet boards: 4a - glue, 4b - at an angle, 4c - laying on a wooden base, 4d - laying on joists. The first row of panels is laid with the left side of the lock (see Fig. 2) to the wall with a gap of about 1 cm and secured with wedges. The direction is taken along the daylight falling from the window. Each new row usually begins with the remainder of the previous one, if it is not less than 0.5 m. It is necessary to ensure that dirt and sand do not get into the locking joint. A wooden block can be used to finish off the joined boards. If desired, the locking joints of the boards can be glued. This is done not to fix the joints, but to protect against water spilled on the floor. To make the pipe outline, apply a board to them, make markings (see Fig. 3a and 3b), drill holes 2 cm larger than the pipe diameter and saw off the edge of the board (see Fig. 3c). Then put the board in place and glue the sawn segment (see Fig. 3d). The edge of the hole can be covered with a suitable ring. The boards of the last row are cut to the required width taking into account the expansion gap, the locking edge is cut off from the groove of the boards of the penultimate row, and glue is applied to the groove. After this, the boards are carefully put in place using a stop bracket. Expansion wedges are installed in the expansion gap. After laying is complete, the wedges are removed from the expansion gap along the entire perimeter of the floor and the baseboard is installed. The baseboard is attached only to the wall. Return to Contents</a>

Adhesive way of laying

Laying parquet on screed.As with the previous method, the concrete screed should be as smooth, clean and dry as possible. Its maximum permissible humidity is 3%. Sheets of moisture-resistant plywood no larger than 100x100 cm and at least 10 mm thick are laid on it. They are laid with expansion gaps of at least 5 mm wide. After laying, the plywood is carefully sanded. Each manufacturer of parquet boards recommends a certain adhesive composition for gluing their products. It is better not to violate these recommendations. Glue is applied to the base using a notched trowel. For better adhesion, the boards can be tapped after laying using a wooden block (see Fig. 4a). The structure will be stronger and more reliable if each parquet board is fastened to the plywood with self-tapping screws screwed through the ridge at an angle of about 45º (see Fig. 4b). The heads of the screws are countersunk into the board. It is better to lay the flooring along the long wall of the room, and the joints should be at least 0.5 m apart. Do not forget to leave expansion gaps of 1 cm between the flooring and the walls, as well as around the pipes. After laying, they are covered with baseboards and decorative cuffs. The glue should dry for at least 24 hours. Return to contents</a>

Laying parquet on screed.As with the previous method, the concrete screed should be as smooth, clean and dry as possible. Its maximum permissible humidity is 3%. Sheets of moisture-resistant plywood no larger than 100x100 cm and at least 10 mm thick are laid on it. They are laid with expansion gaps of at least 5 mm wide. After laying, the plywood is carefully sanded. Each manufacturer of parquet boards recommends a certain adhesive composition for gluing their products. It is better not to violate these recommendations. Glue is applied to the base using a notched trowel. For better adhesion, the boards can be tapped after laying using a wooden block (see Fig. 4a). The structure will be stronger and more reliable if each parquet board is fastened to the plywood with self-tapping screws screwed through the ridge at an angle of about 45º (see Fig. 4b). The heads of the screws are countersunk into the board. It is better to lay the flooring along the long wall of the room, and the joints should be at least 0.5 m apart. Do not forget to leave expansion gaps of 1 cm between the flooring and the walls, as well as around the pipes. After laying, they are covered with baseboards and decorative cuffs. The glue should dry for at least 24 hours. Return to contents</a>

Other ways of laying a parquet board

Almost the same as the previous method,the technology of laying on a wooden base looks like (see Fig. 4c). It should be especially noted that the parquet boards are laid perpendicular to the floorboards. Before laying, the wooden floors are cleaned and, if possible, leveled with a grinding machine. Loose floorboards should be adjusted into place. Technological table of parquet.It is advisable to lay waterproofing on a wooden base. If there is no special underlay, it can be replaced with polyethylene film. Glue is not applied to the base, but to increase the strength of the coating, the grooves and ridges of the panels are coated with glue along the entire length. Thanks to this, the panels are glued together. Another method is laying on joists (see Fig. 4g). These are wooden beams with a rectangular cross-section. A distance of more than 0.4 m between individual joists is unacceptable. They must all be pre-leveled to a single level. The main difficulty is the empty spaces between the joists. The parquet boards used in this method must be thick enough - at least 22 mm. As in the previous method, they are glued together with their side surfaces. If the work is done taking into account all these recommendations, the result will satisfy the most demanding inhabitant of a renovated apartment.</ ul>

Technological table of parquet.It is advisable to lay waterproofing on a wooden base. If there is no special underlay, it can be replaced with polyethylene film. Glue is not applied to the base, but to increase the strength of the coating, the grooves and ridges of the panels are coated with glue along the entire length. Thanks to this, the panels are glued together. Another method is laying on joists (see Fig. 4g). These are wooden beams with a rectangular cross-section. A distance of more than 0.4 m between individual joists is unacceptable. They must all be pre-leveled to a single level. The main difficulty is the empty spaces between the joists. The parquet boards used in this method must be thick enough - at least 22 mm. As in the previous method, they are glued together with their side surfaces. If the work is done taking into account all these recommendations, the result will satisfy the most demanding inhabitant of a renovated apartment.</ ul>