There are several methods to level the floor, butthe most popular is the wet method. Do-it-yourself concrete floor screed is most often done. A cement-sand mixture is prepared for the work, it is poured onto the base. You can make the screed yourself, this method can level almost any base. Installation of floor screed.Preliminary waterproofing is carried out, special beacons are installed. After that, the concrete mixture is mixed and pouring is performed according to the previously made markings and beacons. After pouring, it is necessary to wait a certain time for drying and gaining strength, this usually takes about 28 days.

Installation of floor screed.Preliminary waterproofing is carried out, special beacons are installed. After that, the concrete mixture is mixed and pouring is performed according to the previously made markings and beacons. After pouring, it is necessary to wait a certain time for drying and gaining strength, this usually takes about 28 days.

Preparing for pouring

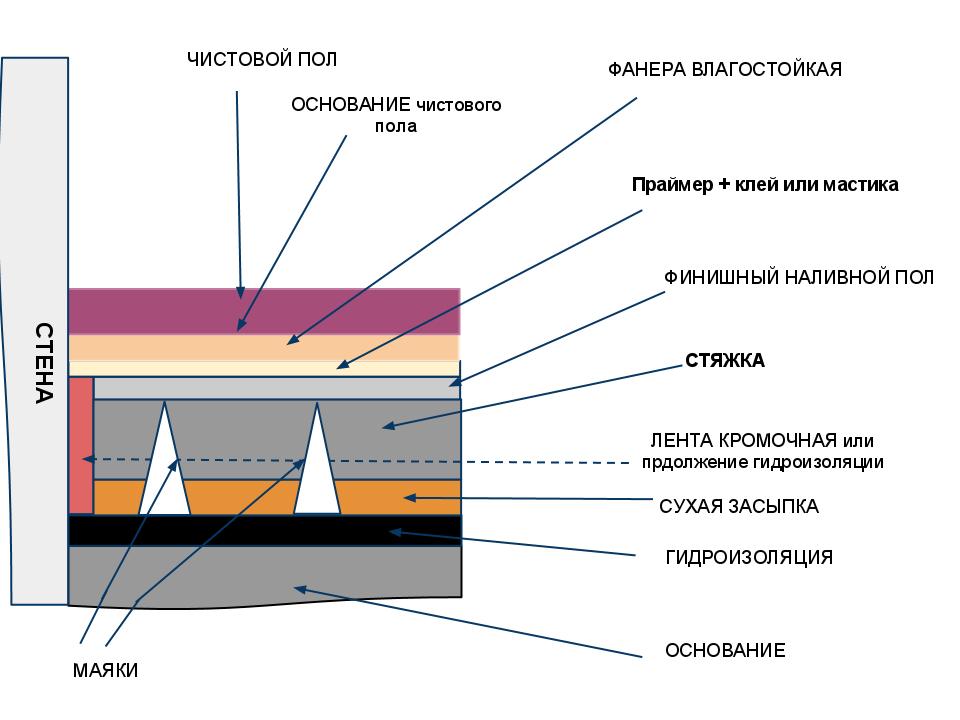

Before you do the floor screed yourself, the base is carefully prepared. The sequence of actions is as follows: Scheme of the screed pouring process.

Scheme of the screed pouring process.

Once the base is prepared, you can begin mixing the mixture. You will need the following:

- cement and sand, clean water;

- fillers, plasticizers, if necessary;

- a container for mixing the solution;

- building mixer;

- for a clear compliance with the proportions it is necessary to use special scales;

- protective gloves for hands.

Preparation of the solution: Scheme of the device of a warm floor in a screed.

Scheme of the device of a warm floor in a screed.

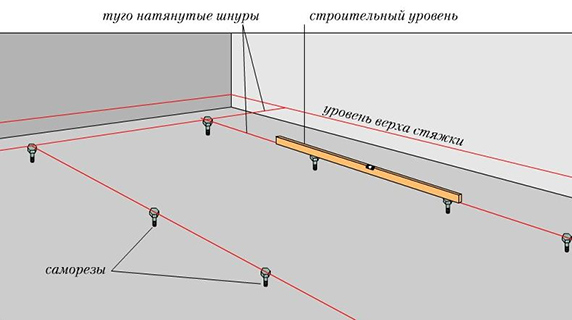

To perform a high-quality fill, it is necessaryinstall guides or beacons on the surface. The former are made of metal profiles, while the role of beacons can be played by columns of cement mortar. Their height should be sufficient to level the surface. Return to contents</a>

Fill rules

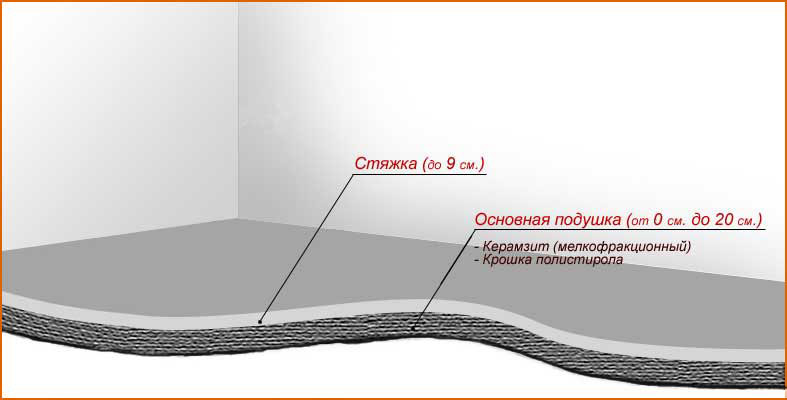

Scheme of the device of semi-dry screed.Various mixtures can be used for floor screeds. Not only standard cement-sand screeds are used, but also self-leveling mixtures, which are applied much easier and faster, their quality is higher. However, a regular screed based on cement-sand mortar is used more often. The process of applying the composition is simple, you only need to calculate the amount of cement in advance. Do-it-yourself floor screed is not so difficult, but it is best done by two people, one person will mix the solution, and the other will do the pouring. The solution cannot be mixed in full at once, it quickly loses its qualities. It is best to make a small part of it, and while it is being poured, mix the next one. It is recommended to start the screed from the far corner of the room, moving towards the exit. This will help to avoid walking on freshly laid concrete. The solution is laid out on the surface along the pre-made markings and beacons (or guides), after which the pouring is leveled with a trowel and a rule. Leveling is done with oval movements, it is similar to grouting walls. If you work together, the process can be organized correctly and quickly. While one person fills and levels the surface, the second one has time to mix the next portion of the solution. In this case, the consumption of concrete can be reduced. It will take no more than 1 day to screed the floor in a small room. Return to the table of contents</a>

Scheme of the device of semi-dry screed.Various mixtures can be used for floor screeds. Not only standard cement-sand screeds are used, but also self-leveling mixtures, which are applied much easier and faster, their quality is higher. However, a regular screed based on cement-sand mortar is used more often. The process of applying the composition is simple, you only need to calculate the amount of cement in advance. Do-it-yourself floor screed is not so difficult, but it is best done by two people, one person will mix the solution, and the other will do the pouring. The solution cannot be mixed in full at once, it quickly loses its qualities. It is best to make a small part of it, and while it is being poured, mix the next one. It is recommended to start the screed from the far corner of the room, moving towards the exit. This will help to avoid walking on freshly laid concrete. The solution is laid out on the surface along the pre-made markings and beacons (or guides), after which the pouring is leveled with a trowel and a rule. Leveling is done with oval movements, it is similar to grouting walls. If you work together, the process can be organized correctly and quickly. While one person fills and levels the surface, the second one has time to mix the next portion of the solution. In this case, the consumption of concrete can be reduced. It will take no more than 1 day to screed the floor in a small room. Return to the table of contents</a>

Dismantle of lighthouses

Scheme of installation of beacons.After the floor screed is completed, the base is left to dry. Attention should be paid to whether guides or beacons were used during installation. If regular guides were used, they must be dismantled after the solution hardens. Then the fill is left until it dries completely. This allows you to preserve the shape of the base and not damage the fill. All traces that remain after removing the profile must be carefully sealed. Beacons are not removed from the solution. This option is considered simpler, it is much more convenient for self-pouring. It is best to use beacons made of cement mortar for this. They are small concrete posts installed at certain points.

Scheme of installation of beacons.After the floor screed is completed, the base is left to dry. Attention should be paid to whether guides or beacons were used during installation. If regular guides were used, they must be dismantled after the solution hardens. Then the fill is left until it dries completely. This allows you to preserve the shape of the base and not damage the fill. All traces that remain after removing the profile must be carefully sealed. Beacons are not removed from the solution. This option is considered simpler, it is much more convenient for self-pouring. It is best to use beacons made of cement mortar for this. They are small concrete posts installed at certain points. Dry floor screed diagram.When does the screed harden? This happens approximately 24 hours after pouring. This does not mean that you can walk on the floor, usually only the guides are removed after 24 hours. The first loads on the floor are possible after approximately 3 weeks, and the full drying period is considered to be 4 weeks. After a month, you can begin further work on finishing the floor, the concrete screed will gain full strength later, but this will not have a significant effect on the quality. After pouring, it is recommended to moisten the floor every day at first so that it does not crack, since during the drying process, the concrete loses moisture, its volume decreases. At first, it is necessary to wet the fill 2 times a day, then you can limit yourself to once. If there is a need to reduce the drying time, it is best to use special additives and plasticizers. They not only increase the strength of the mixture, but also reduce the drying time, which is especially important during the renovation of a residential apartment. Such additives should be used at the stage of mixing the solution. Return to the table of contents</a>

Dry floor screed diagram.When does the screed harden? This happens approximately 24 hours after pouring. This does not mean that you can walk on the floor, usually only the guides are removed after 24 hours. The first loads on the floor are possible after approximately 3 weeks, and the full drying period is considered to be 4 weeks. After a month, you can begin further work on finishing the floor, the concrete screed will gain full strength later, but this will not have a significant effect on the quality. After pouring, it is recommended to moisten the floor every day at first so that it does not crack, since during the drying process, the concrete loses moisture, its volume decreases. At first, it is necessary to wet the fill 2 times a day, then you can limit yourself to once. If there is a need to reduce the drying time, it is best to use special additives and plasticizers. They not only increase the strength of the mixture, but also reduce the drying time, which is especially important during the renovation of a residential apartment. Such additives should be used at the stage of mixing the solution. Return to the table of contents</a>

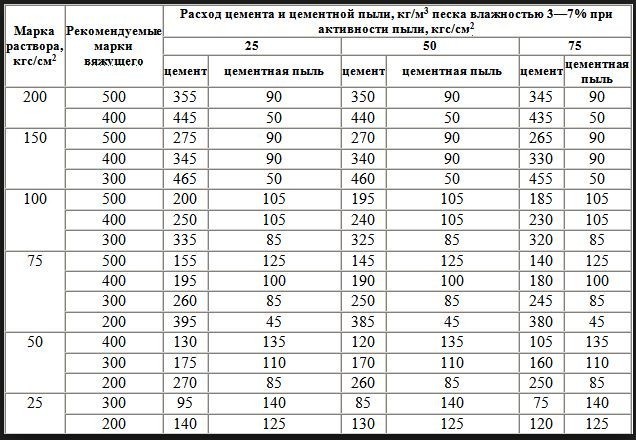

Cement consumption for floor screed

Table for calculating cement for floor screed.It is necessary to pay attention to what ingredients to buy and how much of them you need. The main component is cement, it should be added in a certain proportion. It is best to take ready-made dry mixes, dilute them with water according to the manufacturer's instructions. The mixture can be prepared by hand. You can use fairly simple calculations to determine the amount of cement. It is the wrong calculation that is often the main reason for poor-quality screed, cracking of the surface, the appearance of numerous defects. It is important to remember that the calculation is carried out for 1 cubic meter of ready-made solution, and not for a dry mix. The brand of cement can be different, it is selected taking into account the conditions under which the pouring will be carried out. The most common option for an apartment is pouring using M400 cement. For floor screed, M150 mortar is prepared, cement consumption is 490 kg. 50 kg of M400 cement is required per 1 m² of the base floor in the room, while the screed will have a thickness of 1 cm.

Table for calculating cement for floor screed.It is necessary to pay attention to what ingredients to buy and how much of them you need. The main component is cement, it should be added in a certain proportion. It is best to take ready-made dry mixes, dilute them with water according to the manufacturer's instructions. The mixture can be prepared by hand. You can use fairly simple calculations to determine the amount of cement. It is the wrong calculation that is often the main reason for poor-quality screed, cracking of the surface, the appearance of numerous defects. It is important to remember that the calculation is carried out for 1 cubic meter of ready-made solution, and not for a dry mix. The brand of cement can be different, it is selected taking into account the conditions under which the pouring will be carried out. The most common option for an apartment is pouring using M400 cement. For floor screed, M150 mortar is prepared, cement consumption is 490 kg. 50 kg of M400 cement is required per 1 m² of the base floor in the room, while the screed will have a thickness of 1 cm. Scheme of floor screed with expanded clay.This calculation is universal, it is used quite often for residential premises. For warehouses, garages, non-residential premises, it is best to use a solution of the M200 brand, which is more reliable and durable, resistant to various mechanical impacts. It is important to take into account that during drying and hardening, the volume of the screed decreases, but this process is uneven, affecting not only the area, but also the volume of the mixture. If the calculation is made incorrectly, the surface begins to peel off, become covered with cracks. To prevent this from happening, you must not only pay attention to the proportions, but also wet the surface after pouring. The optimal proportion is 1: 3, i.e. for each kilogram of cement with the M500 brand, you need to take 3 kg of sown sand, water is added in the amount of 0.5 liters. This is how the solution of the M200 brand is obtained. To determine the amount of solution, you need to use the formula: V = width * length * thickness of the screed. Using the previously specified data, you can establish:

Scheme of floor screed with expanded clay.This calculation is universal, it is used quite often for residential premises. For warehouses, garages, non-residential premises, it is best to use a solution of the M200 brand, which is more reliable and durable, resistant to various mechanical impacts. It is important to take into account that during drying and hardening, the volume of the screed decreases, but this process is uneven, affecting not only the area, but also the volume of the mixture. If the calculation is made incorrectly, the surface begins to peel off, become covered with cracks. To prevent this from happening, you must not only pay attention to the proportions, but also wet the surface after pouring. The optimal proportion is 1: 3, i.e. for each kilogram of cement with the M500 brand, you need to take 3 kg of sown sand, water is added in the amount of 0.5 liters. This is how the solution of the M200 brand is obtained. To determine the amount of solution, you need to use the formula: V = width * length * thickness of the screed. Using the previously specified data, you can establish:

- a 490 kg of cement is required per 1 cu.

- mixture cube — 490*V/1.

Cement is usually purchased in 50 kg bags.The resulting number must be divided by 50, the value rounded up. As a result, you can prepare a high-quality floor solution that will last a long time. Concrete screed is often used to level the floor, it allows you to get a flat and smooth surface. After the mixture dries, you can use any floor material, since the characteristics of the screed are quite high. You can make such a screed yourself, it is only important to clearly follow all the stages of the work.