A special mood for the entire room can be given by lamps that are made with your own hands. Such a product fully reflects the individuality of the owner. Wall lamps emit a subdued light, creating a quiet and calm atmosphere. Modern materials allow you to use all their diversity, so that you can (sconces).

Wall lamps emit a subdued light, creating a quiet and calm atmosphere. Modern materials allow you to use all their diversity, so that you can (sconces).

Materials for fixtures

The source material from which it can be made can be: You can use different branches to make a wall lamp.

You can use different branches to make a wall lamp.

- Wooden twigs, brushwood, large branches of any size and unusual shape;

- paper of different density and texture (rice, cardboard);

- a wire that can be bent by hand, but it keeps the shape well for a long time;

- Natural material, for example, dried leaves or flowers;

- textiles of any quality and density;

- threads of different thickness and texture (thin and smooth or coarse and thick).

And this is only a small part of the source materials.for creativity. In order to do, you just need to turn on your imagination, be patient, and then you can get a real masterpiece. In addition, if the interior is changing, then the lamps can be remade with your own hands to match the new motives of the room. It should be borne in mind that if flammable materials are used as a lampshade, for example, fabrics, paper, wood, then the light bulb that will be mounted inside must be energy-saving. This will allow the outer materials of the lamp not to overheat, and the risk of fire in the room can be avoided. If you plan to use only incandescent lamps, then you need to think about the design of the lampshade from materials that are resistant to heat and do not deform under prolonged exposure to temperature. Use as a base for the lampan old chandelier socket. Sockets from old chandeliers, floor lamps or other lighting fixtures can serve as a base for a wall lamp. The only requirement is the integrity of the base. It determines how long the lamp itself will last. The color of the wall lamp can be changed using spray paint or originally multi-colored materials. Most modern materials lend themselves well to gluing. But most often, to get a reliable lamp, a heating gun with glue is used. It can serve as an additional insulator when twisting wires, and is also not afraid of temperature exposure. It is capable of gluing together materials of different origins, for example, plastic and paper. But if the lamp is made with your own hands only from paper, textiles, that is, from materials for which the use of such glue is not at all necessary, then PVA is used. It securely holds the entire structure together. Return to contents</a>

Use as a base for the lampan old chandelier socket. Sockets from old chandeliers, floor lamps or other lighting fixtures can serve as a base for a wall lamp. The only requirement is the integrity of the base. It determines how long the lamp itself will last. The color of the wall lamp can be changed using spray paint or originally multi-colored materials. Most modern materials lend themselves well to gluing. But most often, to get a reliable lamp, a heating gun with glue is used. It can serve as an additional insulator when twisting wires, and is also not afraid of temperature exposure. It is capable of gluing together materials of different origins, for example, plastic and paper. But if the lamp is made with your own hands only from paper, textiles, that is, from materials for which the use of such glue is not at all necessary, then PVA is used. It securely holds the entire structure together. Return to contents</a>

Technology of manufacturing of devices

Wall lamps can servealternative to overhead lighting, that is, the need to use a chandelier is completely eliminated, and it can be dismantled. This will allow you to change the configuration of the canvas or its finish. In order to make a wall lamp with your own hands, you need the following materials and tools: To create the lamp you will need: a jigsaw, a drill with bits, a screwdriver, a tape measure, a grinder.

To create the lamp you will need: a jigsaw, a drill with bits, a screwdriver, a tape measure, a grinder.

- electric jigsaw or saw with fine teeth;

- grinding machine or sandpaper with different granularity;

- drill and set of drills to it for wood;

- Screwdriver;

- tape measure and pencil;

- sheet MDF (not very dense) or OSB thickness of 19 mm;

- putty mixture on wood;

- paint or a colored can.

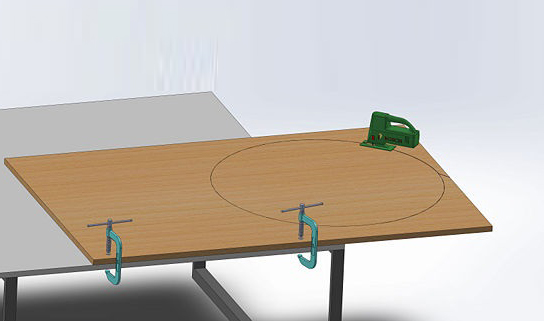

DIY lamps of similar designStart by cutting a rectangle from an OSB sheet, which will be the base for the lamp. The geometric dimensions of the front part are pre-calculated based on the dimensions of the lamps and the room. Daylight lamps are best suited for such a lamp. They have good light output with low consumption and heating. Add 10-20 cm from the end and 5-10 cm to the length of its part to the size of the lamp. Also add the thickness of the sides, which are made from the same sheet as the main part of the lighting fixture. Thus, you get the overall size of the lamp. Now you need to make several rectangular cuts in it. Their number and width are determined by the lighting requirements of the room. If you need to have enough light in the room, then cut out 2-3 wide cuts, then 3 and 5 lamps will be used, respectively. If strong illumination is not required, then you can get by with 1 cut and 2 lamps. In this case, you should take into account the width of the lamps to be installed later. You can cut out the slots using a jigsaw. In order to make the baselamp, it is necessary to cut a square or circle out of the MDF sheet. First, they are marked with a tape measure and a pencil. Next, holes are drilled in the corners, which will serve as a starting point for the cut. After the holes are made, they are sanded with a machine or manually with sandpaper. The lamps are applied to the back part and their mounting locations are marked. Next, holes are drilled into which the fastening will be carried out. Four sidewalls are cut out of the OSB sheet for the perimeter of the base and the same number for framing each of the slots. The dimensions of the large ones should be such that when mounted on the main part of the lamp, there are still 5-10 cm left around the entire perimeter. But the side parts themselves adjoin each other without gaps. This will make the structure airy. At the same time, it is necessary to provide a distance of 2-3 cm between the sidewalls on one of the lower sides in order to pull the wires from the lamps through it. The dimensions of the sidewalls that frame the slots are determined by their dimensions. Before further use, they must be processed with sandpaper or a grinding machine. The sides are applied to the back of the lamp and secured with screws. Additionally, the surfaces can be treated with glue. After this, the entire frame must be clamped with clamps and wait until the glue dries completely. Return to contents</a>

In order to make the baselamp, it is necessary to cut a square or circle out of the MDF sheet. First, they are marked with a tape measure and a pencil. Next, holes are drilled in the corners, which will serve as a starting point for the cut. After the holes are made, they are sanded with a machine or manually with sandpaper. The lamps are applied to the back part and their mounting locations are marked. Next, holes are drilled into which the fastening will be carried out. Four sidewalls are cut out of the OSB sheet for the perimeter of the base and the same number for framing each of the slots. The dimensions of the large ones should be such that when mounted on the main part of the lamp, there are still 5-10 cm left around the entire perimeter. But the side parts themselves adjoin each other without gaps. This will make the structure airy. At the same time, it is necessary to provide a distance of 2-3 cm between the sidewalls on one of the lower sides in order to pull the wires from the lamps through it. The dimensions of the sidewalls that frame the slots are determined by their dimensions. Before further use, they must be processed with sandpaper or a grinding machine. The sides are applied to the back of the lamp and secured with screws. Additionally, the surfaces can be treated with glue. After this, the entire frame must be clamped with clamps and wait until the glue dries completely. Return to contents</a>

Shutdown

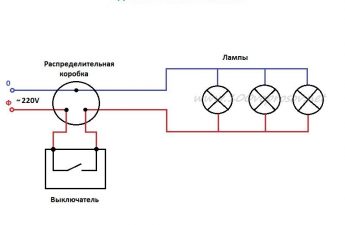

Scheme of installation of a lamp in a light fixture.As soon as the glue has dried, you can start attaching the lamps. They are secured with screws in the prepared holes. In addition, you need to ensure that the wires from them come out in one direction. When the lamps are secured, the wires are pulled through the prepared gap between the sides. Then they are twisted and connected to the socket through the switch. The lamp is turned over to the front side and the screw heads are sealed with putty. This must be done along the entire frame. After it hardens, these places are treated with sandpaper. All surfaces are treated with a primer. It will cover with a protective layer, in addition, paint consumption will be significantly reduced. The inside of the lamp can be painted white. This will provide additional illumination due to the reflection of light from the inner surface. After this, the outside of the lamp is painted. For this, you can use any colored paint or an aerosol can. If necessary, apply several layers. To give the surface of the lamp a glossy shade, you can apply a layer of varnish over all layers of paint after it has completely dried. Mounting on the wall is carried out on dowels and hooks, which are located on the back surface of the side parts of the lighting fixture. Such lamps can be installed with your own hands in the hallway, in the kitchen or in the country house.</ ul>

Scheme of installation of a lamp in a light fixture.As soon as the glue has dried, you can start attaching the lamps. They are secured with screws in the prepared holes. In addition, you need to ensure that the wires from them come out in one direction. When the lamps are secured, the wires are pulled through the prepared gap between the sides. Then they are twisted and connected to the socket through the switch. The lamp is turned over to the front side and the screw heads are sealed with putty. This must be done along the entire frame. After it hardens, these places are treated with sandpaper. All surfaces are treated with a primer. It will cover with a protective layer, in addition, paint consumption will be significantly reduced. The inside of the lamp can be painted white. This will provide additional illumination due to the reflection of light from the inner surface. After this, the outside of the lamp is painted. For this, you can use any colored paint or an aerosol can. If necessary, apply several layers. To give the surface of the lamp a glossy shade, you can apply a layer of varnish over all layers of paint after it has completely dried. Mounting on the wall is carried out on dowels and hooks, which are located on the back surface of the side parts of the lighting fixture. Such lamps can be installed with your own hands in the hallway, in the kitchen or in the country house.</ ul>