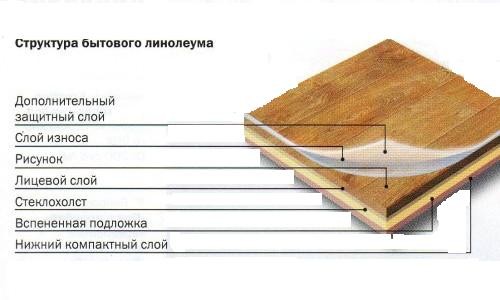

Linoleum is one of the most famous typesfloor coverings. It differs from other materials by its relative cheapness. In addition, it is easy to clean from dirt and is a good waterproofing agent. For these reasons, some of those home craftsmen who arrange a warm floor in their home prefer linoleum. Structure of household linoleum.True, its thermal conductivity characteristics are worse than, for example, those of porcelain stoneware or tiles. Therefore, it is necessary to know which linoleum covering after installation will most effectively transfer heat from the coolant to the room. In addition, it is necessary to choose a material that is more environmentally friendly for use in the home.

Structure of household linoleum.True, its thermal conductivity characteristics are worse than, for example, those of porcelain stoneware or tiles. Therefore, it is necessary to know which linoleum covering after installation will most effectively transfer heat from the coolant to the room. In addition, it is necessary to choose a material that is more environmentally friendly for use in the home.

What kind of linoleum to choose for flooring on the warm floor

There are currently 5 specieslinoleum covering. To choose a material for laying on a heated floor, you do not have to be a specialist. You just need to know what markings are used to mark products suitable for heated floors. A sample marking is shown in Fig. 1. Next to it, the maximum temperature at which the linoleum can be used is also applied. You should not stop your choice on an alkyd material, as well as a nitrocellulose or rubber coating. Figure 1. Sample marking of linoleum for underfloor heating.

Figure 1. Sample marking of linoleum for underfloor heating.

There are 2 types of coating that can be used for finishing the heated floor:

- marmoleum (material on a natural basis);

- PVC linoleum.

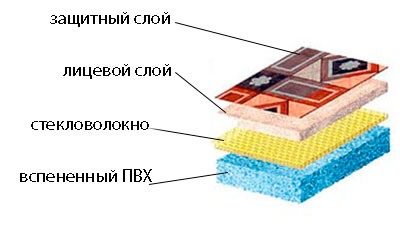

PVC linoleum diagram.But these materials retain their original characteristics only until heated to a certain temperature. PVC flooring can withstand 30°C, and the maximum permissible temperature for marmoleum is 27°C. It is worth mentioning that PVC material will have a strong odor in the first weeks after installation, but the odors will disappear after a while. In addition, when buying PVC flooring, choose material for commercial or semi-commercial use. It should be no thicker than 1.5 mm and should not have an insulating backing, which reduces the thermal conductivity of the flooring. Of course, when making a heated floor under , do not forget to equip it with a thermostat that maintains the temperature of the finishing coating within acceptable limits. Return to contents</a>

PVC linoleum diagram.But these materials retain their original characteristics only until heated to a certain temperature. PVC flooring can withstand 30°C, and the maximum permissible temperature for marmoleum is 27°C. It is worth mentioning that PVC material will have a strong odor in the first weeks after installation, but the odors will disappear after a while. In addition, when buying PVC flooring, choose material for commercial or semi-commercial use. It should be no thicker than 1.5 mm and should not have an insulating backing, which reduces the thermal conductivity of the flooring. Of course, when making a heated floor under , do not forget to equip it with a thermostat that maintains the temperature of the finishing coating within acceptable limits. Return to contents</a>

Kinds of warm floors

You can install one of three types of heated floors in your home:

- water;

- infrared;

- electric.

Scheme for installation of electric underfloor heating.Each of them has its own advantages and disadvantages. Water floors are the most labor-intensive to install, but they are successfully used as a heating system without high costs for daily operation. Their installation is difficult in apartments with centralized heating, since the installation of a water-heated floor is possible only after agreement with utilities. In addition, laying such a floor is associated with a decrease in the height of the room, since a screed is poured onto the base in 2 layers. The operation of electric and infrared floors is associated with increased energy consumption. However, it is worth noting that the heat carriers of the infrared floor consume 1.5-2 times less energy than the heating cables of the electric one. At the same time, the installation of both is much less labor-intensive than the construction of a water-heated floor. It should be added that an electric base can be unsafe. In addition, it can cause overheating of the linoleum covering, so the electric heating floor will have to be removed from the list. It turns out that the best option for a warm floor under linoleum is an infrared base, since it evenly heats all areas of the finishing coating, preventing it from overheating. Return to contents</a>

Scheme for installation of electric underfloor heating.Each of them has its own advantages and disadvantages. Water floors are the most labor-intensive to install, but they are successfully used as a heating system without high costs for daily operation. Their installation is difficult in apartments with centralized heating, since the installation of a water-heated floor is possible only after agreement with utilities. In addition, laying such a floor is associated with a decrease in the height of the room, since a screed is poured onto the base in 2 layers. The operation of electric and infrared floors is associated with increased energy consumption. However, it is worth noting that the heat carriers of the infrared floor consume 1.5-2 times less energy than the heating cables of the electric one. At the same time, the installation of both is much less labor-intensive than the construction of a water-heated floor. It should be added that an electric base can be unsafe. In addition, it can cause overheating of the linoleum covering, so the electric heating floor will have to be removed from the list. It turns out that the best option for a warm floor under linoleum is an infrared base, since it evenly heats all areas of the finishing coating, preventing it from overheating. Return to contents</a>

Installation of a warm floor

Return to Contents</a>How to lay an infrared floor Laying an infrared heated floor under linoleum is not difficult. To work, you need to purchase:

- thermo film;

- contact clamps;

- electrical wiring;

- insulating materials;

- thermoregulator;

- temperature sensor;

- dielectric heat insulator;

- conductive scotch tape;

- waterproofing.

Figure 2.Wiring diagram for infrared floor sheets. The base for the infrared floor should be cleaned of dust and dirt, dried and leveled. A waterproofing membrane is laid on it, and a thermal insulation film is laid on top. It is better to use a foil membrane with a coating that does not conduct electricity as a thermal insulator. The reflective surface of the thermal insulation should be directed upward. Adjacent, tightly laid strips of thermal insulation are glued together with ordinary tape. The infrared film is laid directly on the thermal insulator. The sheets of warm floor are cut so that the warm floor is not under objects that do not have an air gap with the floor covering. In addition, the distance from the film to the walls should be from 10 to 40 cm. If the room is heated only by this material, its area should occupy at least 70% of the room space. Adjacent strips of warm floor are not laid overlapping. You can fix their position after laying with masking tape. Lay the heater so that the copper parts of the contacts are directed downwards and towards the thermostat, which is attached to the wall. The maximum length of the heating strip should not exceed 8 m. One regulator sets the temperature on an area of 10-15 m2. Fig. 2 shows the connection diagram of the sheets. They are all connected in parallel. The contact clamps are attached to the copper strips with pliers. The wiring is installed. After this, the contacts are insulated. The temperature sensor is insulated and placed under the film. After connecting to the network, the operability of the infrared floor is checked. Additional protection against electric shock will be provided by grounding the film with conductive tape connected to the grounding wire of the network. Linoleum is laid not on the warm floor itself, but on moisture-resistant plywood laid on it. Return to contents</a>Installation of a water floor Before installing a warm floorthe floor under the linoleum is removed from the old screed to the main base. This allows you to repair the floor and achieve smaller losses in the height of the room. After removing the remains of the old coating, dust and dirt in the base, cracks and potholes are sealed with a solution. In addition, protrusions are knocked off its surface. After drying the floor and treating it with an antiseptic, a waterproofing layer of polyethylene or roofing felt is laid.

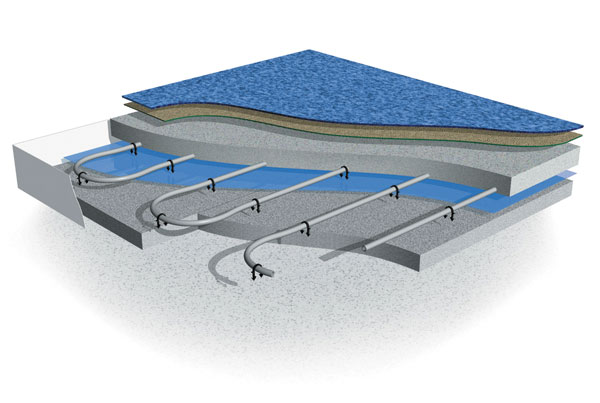

Figure 2.Wiring diagram for infrared floor sheets. The base for the infrared floor should be cleaned of dust and dirt, dried and leveled. A waterproofing membrane is laid on it, and a thermal insulation film is laid on top. It is better to use a foil membrane with a coating that does not conduct electricity as a thermal insulator. The reflective surface of the thermal insulation should be directed upward. Adjacent, tightly laid strips of thermal insulation are glued together with ordinary tape. The infrared film is laid directly on the thermal insulator. The sheets of warm floor are cut so that the warm floor is not under objects that do not have an air gap with the floor covering. In addition, the distance from the film to the walls should be from 10 to 40 cm. If the room is heated only by this material, its area should occupy at least 70% of the room space. Adjacent strips of warm floor are not laid overlapping. You can fix their position after laying with masking tape. Lay the heater so that the copper parts of the contacts are directed downwards and towards the thermostat, which is attached to the wall. The maximum length of the heating strip should not exceed 8 m. One regulator sets the temperature on an area of 10-15 m2. Fig. 2 shows the connection diagram of the sheets. They are all connected in parallel. The contact clamps are attached to the copper strips with pliers. The wiring is installed. After this, the contacts are insulated. The temperature sensor is insulated and placed under the film. After connecting to the network, the operability of the infrared floor is checked. Additional protection against electric shock will be provided by grounding the film with conductive tape connected to the grounding wire of the network. Linoleum is laid not on the warm floor itself, but on moisture-resistant plywood laid on it. Return to contents</a>Installation of a water floor Before installing a warm floorthe floor under the linoleum is removed from the old screed to the main base. This allows you to repair the floor and achieve smaller losses in the height of the room. After removing the remains of the old coating, dust and dirt in the base, cracks and potholes are sealed with a solution. In addition, protrusions are knocked off its surface. After drying the floor and treating it with an antiseptic, a waterproofing layer of polyethylene or roofing felt is laid. Figure 3.Scheme of the pie of a water-heated floor under linoleum. The leveling screed is poured after the beacons are set on the horizontal plane. Instead of a wet screed, the leveling can be done with expanded clay, which is rammed and also leveled along the beacons. A heat insulator made of polystyrene plates equipped with guides for laying pipes, or a foil film is placed on the first screed. A reinforcing grid must be laid on it, to which water pipes made of seamless metal-plastic with a cross-section of ½ inch will be attached. A damper tape is glued to the wall along the perimeter of the room to compensate for thermal expansion. Fig. 3 shows the scheme of the pie of a water-heated floor under linoleum. Remember that:

Figure 3.Scheme of the pie of a water-heated floor under linoleum. The leveling screed is poured after the beacons are set on the horizontal plane. Instead of a wet screed, the leveling can be done with expanded clay, which is rammed and also leveled along the beacons. A heat insulator made of polystyrene plates equipped with guides for laying pipes, or a foil film is placed on the first screed. A reinforcing grid must be laid on it, to which water pipes made of seamless metal-plastic with a cross-section of ½ inch will be attached. A damper tape is glued to the wall along the perimeter of the room to compensate for thermal expansion. Fig. 3 shows the scheme of the pie of a water-heated floor under linoleum. Remember that:

- for heating 1 m2 of floor for linoleum you need 5 m of pipe;

- the first heating circuit is heated floor in an area of not more than 40 m2;

- adjacent tubes are located at a distance of 0.3 m from each other;

- the pipeline is fixed to the crate in every meter;

- There should not be any couplings, fittings, etc. inside the circuit.

After laying the pipeline and connecting itends to the collector, which regulates the supply of coolant, another reinforcing grid is mounted on the pipes and beacons are placed. But before this, it is necessary to carry out pressure testing of the circuit with water. Upon its completion, another screed is poured and leveled. Within 4 weeks, it should completely harden. Before, it is better to apply a self-leveling floor to the surface treated with a primer, which forms a perfectly flat surface. After the self-leveling mixture has hardened, the coating is laid. Traditional technologies using double-sided tape or adhesives are used for its installation.</ ul>