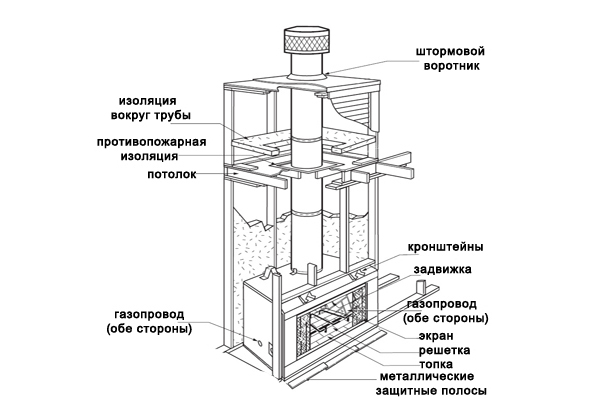

The bio-fireplace runs on bioethanol, whichdoes not emit carbon monoxide during combustion, so it became possible to operate the fireplace without a chimney. During combustion, only carbon dioxide and water are emitted. Any bio-fireplace must have a special burner in which not the liquid fuel itself burns, but bioethanol vapors. The burner provides protection against flash fire, safe ignition and termination of the fireplace combustion. The bio-fireplace is not controlled by fire services, but violation of construction and operation rules can lead to a fire. If the safety of factory-made devices is ensured by their certificates, then the safety of a bio-fireplace built with your own hands is ensured by construction standards and rules. Scheme of the bio-fireplace device.However, a bio-fireplace is not a decorative fireplace in the usual sense and not an imitation of a fireplace. The temperature of the flames in a bio-fireplace is 456°C. The surface of the bio-fireplace firebox heats up to about 150°. Usually the burner is filled about a third, the fireplace burns until the fuel burns out completely for about 3 hours. Usually the burner has a capacity of 2.5-3 liters, its design is very simple. The burner is a steel rectangular container with a damper. A poker is attached to the burner, with the help of which the damper is quickly pushed in, blocking the flame. The burner is ignited with the same poker. When igniting, the burner must have access to a sufficient amount of oxygen. The minimum area of the room in which one burner is used should not be less than 20 m2.

Scheme of the bio-fireplace device.However, a bio-fireplace is not a decorative fireplace in the usual sense and not an imitation of a fireplace. The temperature of the flames in a bio-fireplace is 456°C. The surface of the bio-fireplace firebox heats up to about 150°. Usually the burner is filled about a third, the fireplace burns until the fuel burns out completely for about 3 hours. Usually the burner has a capacity of 2.5-3 liters, its design is very simple. The burner is a steel rectangular container with a damper. A poker is attached to the burner, with the help of which the damper is quickly pushed in, blocking the flame. The burner is ignited with the same poker. When igniting, the burner must have access to a sufficient amount of oxygen. The minimum area of the room in which one burner is used should not be less than 20 m2.

Construction of a fireplace

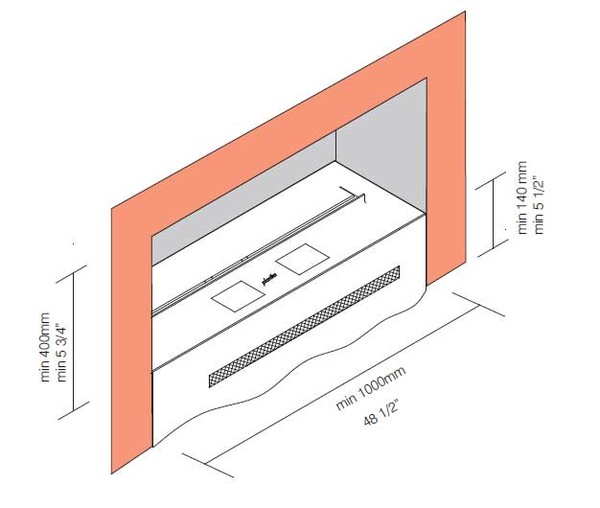

Scheme of the opening for a bio-fireplace.Having a bio-fireplace burner, you can independently build a homemade fireplace in the room in any style, any design. The chamber must be made fireproof. The burner can simply be placed on the bottom of the chamber or built into the bottom. The height of the chamber should be such that there is a distance of 50-70 cm above the flame. The width of the chamber depends on the length of the burner, 15 cm is added to each side. The minimum depth of the finished chamber should be at least 20 cm. If you build a bio-fireplace from gypsum board, you can use the same tools and materials that are used when constructing a partition from gypsum board. Return to contents</a>

Scheme of the opening for a bio-fireplace.Having a bio-fireplace burner, you can independently build a homemade fireplace in the room in any style, any design. The chamber must be made fireproof. The burner can simply be placed on the bottom of the chamber or built into the bottom. The height of the chamber should be such that there is a distance of 50-70 cm above the flame. The width of the chamber depends on the length of the burner, 15 cm is added to each side. The minimum depth of the finished chamber should be at least 20 cm. If you build a bio-fireplace from gypsum board, you can use the same tools and materials that are used when constructing a partition from gypsum board. Return to contents</a>

Tools used:

- perforator;

- Screwdriver;

- scissors for metal;

- Circular Saw;

- the end plane;

- construction knife;

- blades;

- screwdrivers;

- plumb bob;

- level.

Tools for installing a bio-fireplace.The design of a homemade bio-fireplace made of plasterboard can be anything. You can imitate the shape and size of a real fireplace, but there is no need for this for a bio-fireplace. No need to build a chimney tooth, no damper, no smoke collector with a pipe. It is necessary to make a drawing of the fireplace, since precise marking of the frame and base is necessary. The entire structure must be drawn taking into account the cladding. First, you need to think over the design, decide on the dimensions of the fireplace. A metal frame is more suitable than a wooden one. All walls must be double. A layer of stone wool is laid between the plasterboard walls. It is better not to save on insulating material, since ordinary mineral wool contains a lot of fiberglass. A cushion of concrete or a row of bricks as a base will not hurt, as it will create insulation from the floor and raise the chamber above it. It is convenient to make a recess for the burner in concrete or brick. Traditionally, one row of bricks is enough as a base, it can be laid without bandaging the seams. The next row of bricks is laid with bandaging the seams on the mortar. You can use ordinary solid red brick and ready-made fireclay mortar. When the base is ready, formed under the fireplace with a recess for the burner, you can assemble the frame of the rest of the body. The frame is assembled in the usual way on self-tapping screws using perforated corners for more accurate assembly. The wall of the room should also be insulated, so the back wall of the fireplace is made double, with insulation. This is the only way to be sure that the wall is reliably insulated.

Tools for installing a bio-fireplace.The design of a homemade bio-fireplace made of plasterboard can be anything. You can imitate the shape and size of a real fireplace, but there is no need for this for a bio-fireplace. No need to build a chimney tooth, no damper, no smoke collector with a pipe. It is necessary to make a drawing of the fireplace, since precise marking of the frame and base is necessary. The entire structure must be drawn taking into account the cladding. First, you need to think over the design, decide on the dimensions of the fireplace. A metal frame is more suitable than a wooden one. All walls must be double. A layer of stone wool is laid between the plasterboard walls. It is better not to save on insulating material, since ordinary mineral wool contains a lot of fiberglass. A cushion of concrete or a row of bricks as a base will not hurt, as it will create insulation from the floor and raise the chamber above it. It is convenient to make a recess for the burner in concrete or brick. Traditionally, one row of bricks is enough as a base, it can be laid without bandaging the seams. The next row of bricks is laid with bandaging the seams on the mortar. You can use ordinary solid red brick and ready-made fireclay mortar. When the base is ready, formed under the fireplace with a recess for the burner, you can assemble the frame of the rest of the body. The frame is assembled in the usual way on self-tapping screws using perforated corners for more accurate assembly. The wall of the room should also be insulated, so the back wall of the fireplace is made double, with insulation. This is the only way to be sure that the wall is reliably insulated. To make the simplest tabletopA bio-fireplace will require a glass container, stones, pit and lighter fluid. Precautions are necessary in case of a fuel flash during ignition or accidental ignition of spilled fuel inside the chamber. The floor in the room can also flare up very quickly if it is not sufficiently insulated, so it is recommended to protect the floor in front of the fireplace by laying non-combustible material. The painstaking work of finishing the fireplace will require a large number of tools from the home workshop. The volume of work, although small, will require the ability to perform a variety of jobs. If you make the base of the fireplace from brick, then it is advisable to lay out the entire firebox from brick. In this case, only the outer casing is assembled from plasterboard, which can be of a very interesting complex shape. This method of creating a fireproof chamber seems more reliable. A chamber made of high-quality solid brick can be left in its natural form, without finishing. The quality of the masonry must be decent and will require appropriate skills. If they are not there, there is an option of plastering the chamber masonry with fireclay mortar. Finishing with stove tiles and facing with special fireclay plates or stone will do. Decorative facings can be made directly on the plasterboard if the chamber option is chosen from this material. There are many finishing options for both the mantelpiece and the portal. There are no restrictions in choice here, as for a regular fireplace. Accessories are needed as the finishing touch for the bio-fireplace. The burner should be masked with decorative logs, which are sold separately. Bio-fireplace accessories should be made of non-combustible materials.

To make the simplest tabletopA bio-fireplace will require a glass container, stones, pit and lighter fluid. Precautions are necessary in case of a fuel flash during ignition or accidental ignition of spilled fuel inside the chamber. The floor in the room can also flare up very quickly if it is not sufficiently insulated, so it is recommended to protect the floor in front of the fireplace by laying non-combustible material. The painstaking work of finishing the fireplace will require a large number of tools from the home workshop. The volume of work, although small, will require the ability to perform a variety of jobs. If you make the base of the fireplace from brick, then it is advisable to lay out the entire firebox from brick. In this case, only the outer casing is assembled from plasterboard, which can be of a very interesting complex shape. This method of creating a fireproof chamber seems more reliable. A chamber made of high-quality solid brick can be left in its natural form, without finishing. The quality of the masonry must be decent and will require appropriate skills. If they are not there, there is an option of plastering the chamber masonry with fireclay mortar. Finishing with stove tiles and facing with special fireclay plates or stone will do. Decorative facings can be made directly on the plasterboard if the chamber option is chosen from this material. There are many finishing options for both the mantelpiece and the portal. There are no restrictions in choice here, as for a regular fireplace. Accessories are needed as the finishing touch for the bio-fireplace. The burner should be masked with decorative logs, which are sold separately. Bio-fireplace accessories should be made of non-combustible materials.