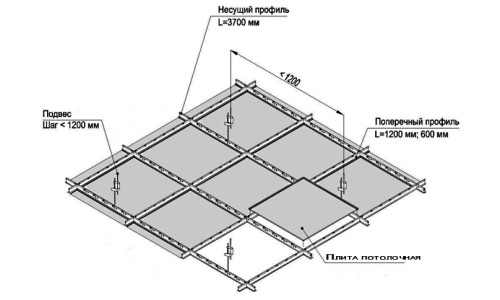

Finishing work can be entrusted to specialists or you can try to build a plastic ceiling yourself. The durability of the structure and its external characteristics will depend on the quality of installation. Scheme of a ceiling made of plastic panels.

Scheme of a ceiling made of plastic panels.

Calculate the number of panels and determine their length

The amount of finishing material will dependfrom the positioning of the design elements. In a standard-sized bathroom (1.5 x 1.7 m), it is recommended to use panels 3 m long (the standard size is 2.4-3 m). They are laid transversely. The products are cut in half to reduce the amount of scraps. The length of the plastic ceiling panels used should be equal to or slightly longer than one side of the room in which the repair work is being carried out (they cannot be connected without a visible seam). After determining the length, the required amount of material is calculated. The standard panel width is 25 cm. You can make a plastic ceiling in a room with the specified dimensions using 4 panels 300 x 25 cm (1.7 x 0.25 x 2 = 3.4). The amount of material is determined by rounding up. The quality of the material affects the quality of the entire structure. Experts advise carefully inspecting the purchased PVC panels. They should have the correct geometry, and the surface should be smooth and with an evenly applied pattern. Scheme of installation of PVC panels on the ceiling.The surface should be smooth and even in appearance and to the touch, without longitudinal and transverse lines, distortions or irregularities. The internal cavity contains stiffening ribs that should not be visible from the outer front side. Experts recommend comparing the number and location of stiffening ribs in several PVC panels of the same size from different manufacturers. A plastic ceiling will be stronger when using products with a large number of ribs. When choosing slabs, take into account the thickness of the outer walls of the material and stiffening ribs. The front side of the product should be thick and strong. It is recommended to take 2 products in advance and try to connect them. The joint should be of high quality and easy, there should be no gaps or traces of assembly between the slabs. The strength of PVC products for finishing a plastic ceiling can be determined by squeezing them. High-quality products do not crack and are practically not deformed. Plastic must be tested for bending. The corner of the product is bent and unbent several times. The material should remain intact after 3-5 bends. Low quality products will be damaged during installation or at the slightest mechanical impact during operation. Return to contents</a>

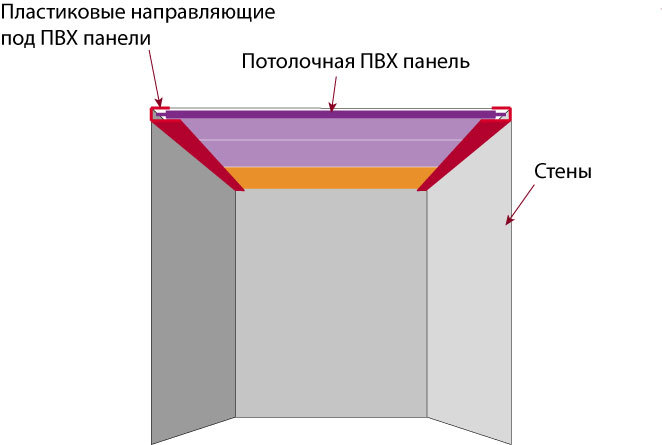

Scheme of installation of PVC panels on the ceiling.The surface should be smooth and even in appearance and to the touch, without longitudinal and transverse lines, distortions or irregularities. The internal cavity contains stiffening ribs that should not be visible from the outer front side. Experts recommend comparing the number and location of stiffening ribs in several PVC panels of the same size from different manufacturers. A plastic ceiling will be stronger when using products with a large number of ribs. When choosing slabs, take into account the thickness of the outer walls of the material and stiffening ribs. The front side of the product should be thick and strong. It is recommended to take 2 products in advance and try to connect them. The joint should be of high quality and easy, there should be no gaps or traces of assembly between the slabs. The strength of PVC products for finishing a plastic ceiling can be determined by squeezing them. High-quality products do not crack and are practically not deformed. Plastic must be tested for bending. The corner of the product is bent and unbent several times. The material should remain intact after 3-5 bends. Low quality products will be damaged during installation or at the slightest mechanical impact during operation. Return to contents</a>

Step-by-step instruction

You can make a ceiling only with the help of high-quality materials and tools. For this you will need: Tools for installing PVC ceilings.

Tools for installing PVC ceilings.

- electric screwdriver or screwdriver;

- electric drill with winning drills;

- Hacksaw for metal or electric jigsaw;

- building angle;

- building level;

- a hammer;

- stool;

- construction roulette;

- pliers;

- pencil;

- building stapler;

- dowels, self-tapping screws, nails, liquid nails.

The mounting profile attachment lines must beMark the perimeter of the ceiling using a building level. It is necessary to achieve the correct horizontal plane. The profile is firmly attached to the wall along the perimeter. There should be no voids or gaps. The transverse profile (the base for attaching the PVC panels) is mounted to the strips fixed along the perimeter of the ceiling. A plastic L-shaped mounting profile is attached to them with self-tapping screws. The space should be filled with PVC slabs after placing internal communications or spotlights, if they are expected to be present. Installation of the slabs begins from the walls. The products are cut with a small hacksaw exactly to length. The first slab is inserted with a tenon into the fixed L-shaped profile and fixed along the entire length with self-tapping screws. The appearance of the future ceiling depends on the correctness of its installation. Self-tapping screws or staples are attached to the far wall of the slab groove in contact with the lathing so that after sheathing the fasteners remain invisible. Subsequent slabs are tightly joined together and attached to the slats of the mounting profile. If the use of a skirting board on the ceiling is not envisaged, it is necessary to insert the edges of all panels into the L-shaped strips of the end walls. The most difficult thing is to install the last PVC panel. Its width must be adjusted to the remaining space. It is cut with a powerful stationery knife. The product is not fixed with screws, but inserted into the groove of the corner, which acts as a casing. It is recommended to install corners along the entire perimeter before starting the installation. The metal mounting profile can be replaced with wooden bars and strips, and the screws - with construction staples. The latter material is cheap and allows you to quickly fix the PVC panels. Construction staples are not recommended for use in rooms with high humidity (kitchen, bathroom, balcony). Professionals know how to make a ceiling from PVC products in dry rooms. For this, they use wooden bars for the frame (4x5 cm or thicker if the installation of spotlights is envisaged). The bars are attached to the ceiling with dowels and screws, maintaining the horizontality and evenness of the plane using a building level. The main metal profile in large rooms should be 2.5 m long. Additional support can be provided to the planks by using hangers that connect the concrete base to the planks (step - 50 cm). You can make a ceiling from plastic slabs quickly and efficiently with your own hands, following the instructions described above.</ ul>