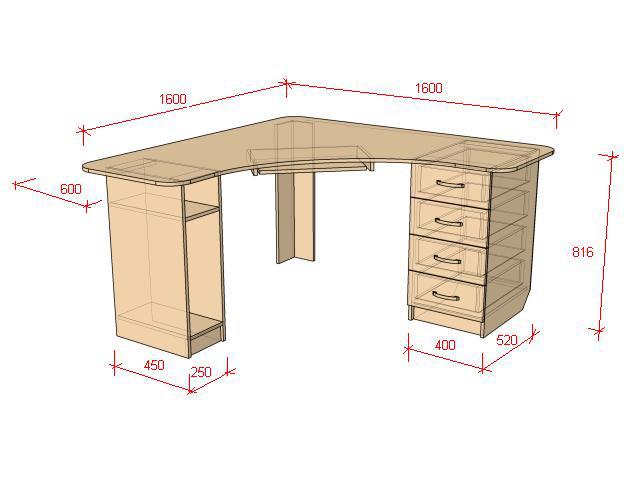

Convenience and comfort are the most important thingscan be in the house. A whole range of furniture accessories are used to form the interior, but among other things, computer tables for the home occupy an important place. Figure 1. Drawing of a corner computer desk.

Figure 1. Drawing of a corner computer desk.

Choice of material and cut

Tools and materials:

- Chipboard;

- roulette;

- pencil;

- electric jigsaw.

Corner Computer Desk Top Schemeстола. Когда изготавливается , нужно учитывать целый ряд факторов: дополнительные функции, габариты, материал и надежность. Всегда хочется сделать максимально надежную конструкцию, но стоить эта затея будет немало, поэтому приходится варьировать идеи. К примеру, для ноутбука можно не монтировать выдвижную панель под клавиатуру, тогда как для стационарного варианта нужно еще и немало места. Обычно используется 2 материала. ДСП пользуется наибольшей популярностью, т.к. стоит очень мало. Работать с ней достаточно просто, а результат получается в тот же день. Цена за материал зависит от двух факторов — толщина и плотность. Для столов под ноутбук можно использовать самые тонкие и хрупкие материалы, но для стационаров придется брать хотя бы средний. Минусы тут тоже достаточно простые — небольшой запас прочности, ограниченная цветовая гамма (цвета можно выбирать любые, но ни один из них не будет идентичен натуральному) и химическая активность, пока есть открытые участки. Мебельный щит, в свою очередь, гораздо надежнее, он идеален в плане экологичности. Работать с ним немного труднее, т.к. древесина немного сложнее поддается обработке, к тому же результат придется ожидать некоторое время (высыхание лака). Этот материал не содержит в себе каких-либо ощутимых минусов, кроме высокой цены и невозможности приобрести в целом ряде городов по всему миру.

Corner Computer Desk Top Schemeстола. Когда изготавливается , нужно учитывать целый ряд факторов: дополнительные функции, габариты, материал и надежность. Всегда хочется сделать максимально надежную конструкцию, но стоить эта затея будет немало, поэтому приходится варьировать идеи. К примеру, для ноутбука можно не монтировать выдвижную панель под клавиатуру, тогда как для стационарного варианта нужно еще и немало места. Обычно используется 2 материала. ДСП пользуется наибольшей популярностью, т.к. стоит очень мало. Работать с ней достаточно просто, а результат получается в тот же день. Цена за материал зависит от двух факторов — толщина и плотность. Для столов под ноутбук можно использовать самые тонкие и хрупкие материалы, но для стационаров придется брать хотя бы средний. Минусы тут тоже достаточно простые — небольшой запас прочности, ограниченная цветовая гамма (цвета можно выбирать любые, но ни один из них не будет идентичен натуральному) и химическая активность, пока есть открытые участки. Мебельный щит, в свою очередь, гораздо надежнее, он идеален в плане экологичности. Работать с ним немного труднее, т.к. древесина немного сложнее поддается обработке, к тому же результат придется ожидать некоторое время (высыхание лака). Этот материал не содержит в себе каких-либо ощутимых минусов, кроме высокой цены и невозможности приобрести в целом ряде городов по всему миру.  Схема крепления мебельных навесов.There are many ways to make a computer desk with your own hands, but for a laptop it is better to make the maximum configuration so that everything is at hand. It has a compartment for the system unit, which can be occupied by any other item. Now you need to cut the chipboard. First, a compartment for the system unit is formed:

Схема крепления мебельных навесов.There are many ways to make a computer desk with your own hands, but for a laptop it is better to make the maximum configuration so that everything is at hand. It has a compartment for the system unit, which can be occupied by any other item. Now you need to cut the chipboard. First, a compartment for the system unit is formed:

- 450x816 mm — 2 pcs.;

- 210x450 - 2 pcs.;

- 250x450 - 1 pc.

Then the office supplies boxes:

- 520x816 - 2 pcs.;

- 350x500 - 4 pcs.;

- 360x500 - 1 pc.;

- 200x400 - 4 pcs.;

- 150x500 - 8 pcs.;

- 350x150 - 4 pcs.;

- 400x816 - 1 pc.

Back leg and table top:

- 200x816 - 2 pcs.;

- 1600х1600 mm, here you need to be careful when cutting, because from both edges an indentation of 600 mm is made, after which they are connected by an internal arc line.

Return to Contents</a>

Performance of works

Computer desk layout. Tools and materials:

Computer desk layout. Tools and materials:

- Screwdriver;

- Screws;

- aluminum corners;

- Furniture handles;

- Chipboard;

- pencil.

Once you have completed the cutting, you need tocarefully sand the cut areas with sandpaper. This is done from the edge to the center so as not to damage the outer laminating coating. Now you can begin to combine the entire structure together according to the diagram (Fig. 1). All assembly work can be carried out in any order, but the completion is always the same. The supporting structure looks like this:

Drawing and view of a small computer desk.All joints are made with screws, for which holes of a smaller diameter are initially drilled. If you forget about the holes, you can make a crack in the chipboard, which will require you to redo most of the work. Each joint is fixed with 2 screws. In the place where the corner is used, only 2 joints are made - below and above, but they should be treated with all attention. If the screwdriver has a depth gauge, then it will not be difficult to drill accurately, but if it is not there, electrical tape is wound on the drill at the required level. The electrical tape will serve as a disposable depth gauge, so it is better to do the work here right away without being distracted by other segments. Now the tabletop is mounted on a computer desk under a laptop. To fix it, you first need to assemble the table and trace the contours of the supporting structures to get a full-fledged drawing from below. After that, you can already make 4 control holes for all the legs. Screws are screwed into the holes in the manner described above, after which the main structure is ready. Return to contents</a>

Drawing and view of a small computer desk.All joints are made with screws, for which holes of a smaller diameter are initially drilled. If you forget about the holes, you can make a crack in the chipboard, which will require you to redo most of the work. Each joint is fixed with 2 screws. In the place where the corner is used, only 2 joints are made - below and above, but they should be treated with all attention. If the screwdriver has a depth gauge, then it will not be difficult to drill accurately, but if it is not there, electrical tape is wound on the drill at the required level. The electrical tape will serve as a disposable depth gauge, so it is better to do the work here right away without being distracted by other segments. Now the tabletop is mounted on a computer desk under a laptop. To fix it, you first need to assemble the table and trace the contours of the supporting structures to get a full-fledged drawing from below. After that, you can already make 4 control holes for all the legs. Screws are screwed into the holes in the manner described above, after which the main structure is ready. Return to contents</a>

Shutdown

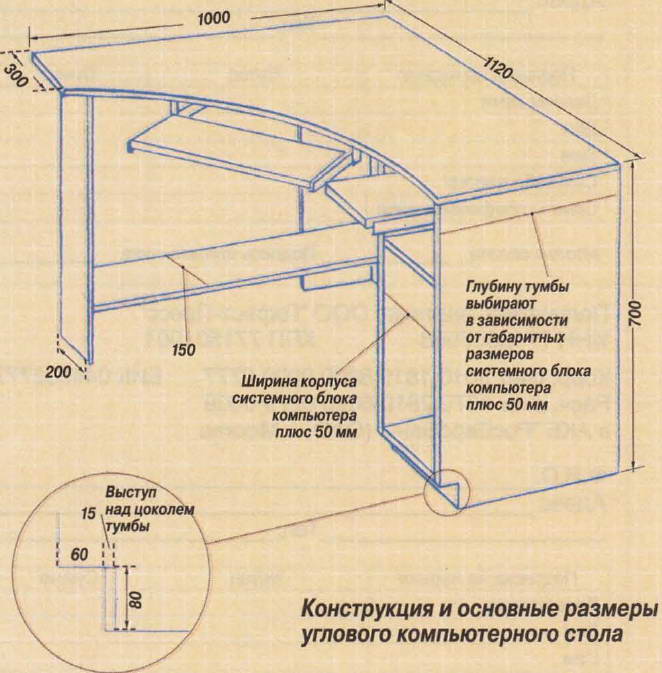

Design scheme and main dimensions of the computer desk. Tools and materials:

Design scheme and main dimensions of the computer desk. Tools and materials:

- edging;

- iron;

- Chipboard;

- screwdriver.

For the computer desk, all that remains is to make the drawers, and all are made according to an identical pattern:

All boxes are being modified in a similar manner.computer desk. The laptop does not need a keyboard, all that remains is to glue the edging along all visible edges of the table, and the work will be completed. To do this, the edging is applied to its place, you need to iron it several times. Now the laptop table is ready for use.</ ul>