The most commonly used material for making furniture with your own hands is laminated chipboard, or laminate. This is a wood chipboard covered with varnish-veneer on one or both sides. Laminate can be used for manufacturingvarious types of furniture, including sliding wardrobes. The properties of this material allow it to be used for a wide variety of furniture: from kitchen furniture to living room furnishings. Positive properties of laminate:

Laminate can be used for manufacturingvarious types of furniture, including sliding wardrobes. The properties of this material allow it to be used for a wide variety of furniture: from kitchen furniture to living room furnishings. Positive properties of laminate:

- it withstands elevated temperatures;

- on sale there are moisture resistant samples of chipboard;

- Has a large color range with a huge variety of shades;

- easy to process;

- can withstand heavy loads, which makes it possible to apply it as a finishing material;

- the price of the chipboard is quite affordable.

It has the following disadvantages:

- it is impossible to create curly details from the laminate;

- when water enters the non-moisture resistant appearance of this material is deformed (swells).

Before using chipboard to createfurniture with your own hands, you need to take into account some nuances of working with it. The main thing is to saw the material so as not to damage its varnish coating. You can do it yourself, but since the sheets are large, it is quite difficult to bring them into the apartment, lay them out and process them. To get rid of this problem, you need to contact a special company that will qualitatively saw the material on the appropriate equipment according to the drawings you bring and process the ends of the parts. Box under the bed made of laminated chipboard When drilling the plate, itshould be placed on a hard surface and pressed firmly - this reduces the number of chips during processing. Chipboard is sold at any construction market or in stores of the same profile. The fittings and components needed to create furniture can be purchased there. The following components can be used to fasten parts of homemade furniture:

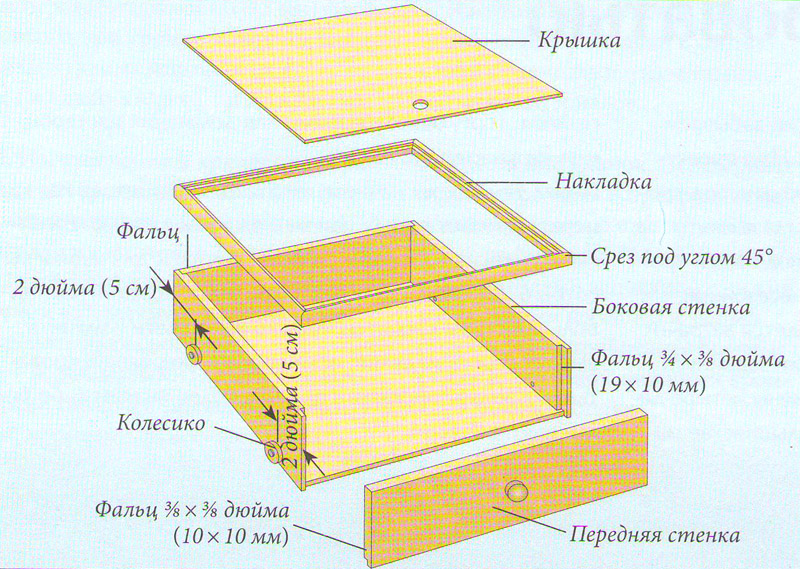

Box under the bed made of laminated chipboard When drilling the plate, itshould be placed on a hard surface and pressed firmly - this reduces the number of chips during processing. Chipboard is sold at any construction market or in stores of the same profile. The fittings and components needed to create furniture can be purchased there. The following components can be used to fasten parts of homemade furniture:

- plastic or metal angles;

- screws or screws.

Plastic corners are available in different colors,which makes it possible to precisely match them to the color of homemade furniture. You can also buy special screws for furniture sets at the construction market. To process laminated chipboard, you will need a tool - an electric drill with a set of drills and a milling cutter. A set of screwdrivers will come in handy, and if you have the opportunity, you can buy a screwdriver - this will save time.

How to make furniture from a laminate?

To do this, first draw up a blueprint of the futurean object or a set (for example, a kitchen). Then, separate parts with all the dimensions are drawn on sheets of Whatman paper. If you do this, you can take ready-made drawings, but then you will need to tie them to the dimensions of your apartment. Drawing of a built-in wardrobe.After completing this work, the necessary material, fittings, components and fasteners are purchased at the construction market to make laminate furniture. Specialists will cut the laminated chipboard to the dimensions indicated in your drawings. When creating future furniture, all parts must be arranged in the order of their assembly. On one side of the workplace, sheets of material, fasteners and other parts are placed, and on the other - the working and marking tool. Such arrangement of the workplace allows you to significantly speed up the assembly process and not waste time searching for the necessary parts or tools. If you need to mark the laminate parts with your own hands, then use a tape measure and a pencil. Future holes are marked in the right places on the surface of the material. They should be at a distance of 5-6 cm from the edge of the sheet, and their location in height depends on the number of shelves in the cabinet. If special screws for furniture are used during assembly, then a drill with a diameter of 8-8.5 mm is used to sink their heads into the material, and for the threaded part - 6-6.2 mm. To avoid distortions, use a metal square to check the correctness of the right angles of the assembled walls of the product. All cabinet parts are screwed together according to the drawings. If it is necessary to install a back wall, then it is cut to the required dimensions from fiberboard using a jigsaw or hacksaw. Then this sheet is either screwed to the cabinet with screws or nailed with small nails from the back side. The ends of all cabinet doors must be pasted over with thin veneer, which should match the color of the base material. Hinges are installed on the cabinet. If they need to be recessed, then a milling cutter with a diameter of 32-32 mm is used to create a recess. Fittings - handles and other elements are installed on the future facades. The doors are hung on the cabinets, which must first be installed in place. This completes the process of creating furniture with your own hands. Return to the table of contents</a>

Drawing of a built-in wardrobe.After completing this work, the necessary material, fittings, components and fasteners are purchased at the construction market to make laminate furniture. Specialists will cut the laminated chipboard to the dimensions indicated in your drawings. When creating future furniture, all parts must be arranged in the order of their assembly. On one side of the workplace, sheets of material, fasteners and other parts are placed, and on the other - the working and marking tool. Such arrangement of the workplace allows you to significantly speed up the assembly process and not waste time searching for the necessary parts or tools. If you need to mark the laminate parts with your own hands, then use a tape measure and a pencil. Future holes are marked in the right places on the surface of the material. They should be at a distance of 5-6 cm from the edge of the sheet, and their location in height depends on the number of shelves in the cabinet. If special screws for furniture are used during assembly, then a drill with a diameter of 8-8.5 mm is used to sink their heads into the material, and for the threaded part - 6-6.2 mm. To avoid distortions, use a metal square to check the correctness of the right angles of the assembled walls of the product. All cabinet parts are screwed together according to the drawings. If it is necessary to install a back wall, then it is cut to the required dimensions from fiberboard using a jigsaw or hacksaw. Then this sheet is either screwed to the cabinet with screws or nailed with small nails from the back side. The ends of all cabinet doors must be pasted over with thin veneer, which should match the color of the base material. Hinges are installed on the cabinet. If they need to be recessed, then a milling cutter with a diameter of 32-32 mm is used to create a recess. Fittings - handles and other elements are installed on the future facades. The doors are hung on the cabinets, which must first be installed in place. This completes the process of creating furniture with your own hands. Return to the table of contents</a>

List of materials and tools for laminate processing with their own hands

- sheets of chipboard cut to size;

- Furniture handles;

- hinges for facades;

- Joints of plastic or metal;

- guides for boxes (if they are in the furniture you made);

- FESCO sheets;

- legs for the cabinet;

- thin veneer;

- furniture screws;

- screws or small nails;

- electric drill with a set of drills;

- Clamps;

- milling cutter;

- a hammer;

- iron;

- jigsaw or hacksaw;

- roulette or metal ruler;

- screwdriver or a set of screwdrivers;

- gonet of metal;

- pencil and sheets of Whatman.

Furniture made by hand shouldfit into the overall interior of your apartment. To do this, it is advisable to first take care of the combination of the color scheme of the made cabinet or kitchen set with the floor and walls in the room where you plan to put the furniture you made with your own hands. If you follow the above recommendations and select high-quality material, even a beginner can make a cabinet.</ ul>