Modern, relatively inexpensive andLaminate is considered a wear-resistant material for flooring - the front floor covering. It differs from other coverings in its beautiful appearance and easy maintenance. Structure of laminate board.The quality of the floors characterizes the level of improvement of the premises and determines the costs of their maintenance and care. You can install such a floor yourself, having previously studied the instructions on the packaging on how to lay the laminate with your own hands.

Structure of laminate board.The quality of the floors characterizes the level of improvement of the premises and determines the costs of their maintenance and care. You can install such a floor yourself, having previously studied the instructions on the packaging on how to lay the laminate with your own hands.

Substrate preparation

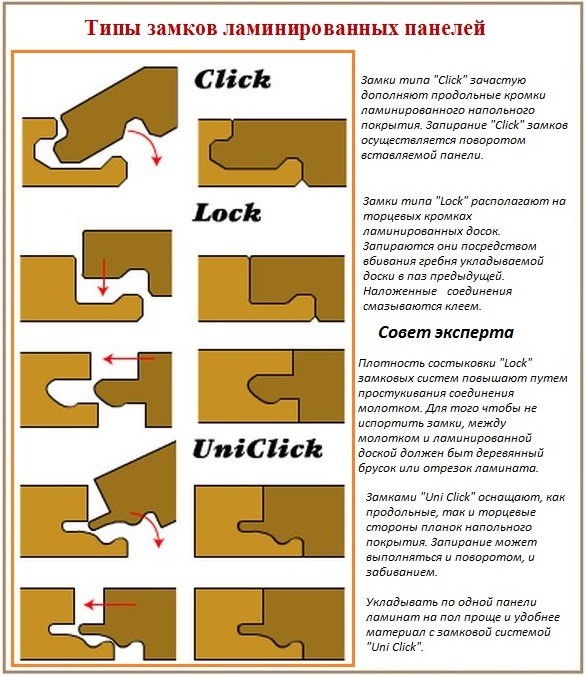

Laying laminate flooring usually begins afterexecution of all construction, installation and finishing works related to possible moistening and contamination of surfaces. Before laying the laminate, it is necessary to carefully level the base, and if necessary, make its screed and clean all the irregularities with a grinder. This will allow you to lay the laminate yourself without any problems. The permissible unevenness of the base can be no more than 3 mm per 1 running meter. It is better to put plywood or fiberboard on a wooden floor. The evenness of the floor is checked with a building level. To improve sound insulation and thermal insulation, a substrate made of natural or synthetic materials is laid under the covering. A substrate made of natural materials is expensive, so it is better to opt for synthetic materials. Types of laminate locking systems:Click, Lock, UniClick. You can use polyethylene foam, extruded polystyrene foam or cork for the underlay. It is best to lay a underlay made of technical cork. The material is expensive and has good performance characteristics. It is highly wear-resistant and is poorly pressed. It has good heat and sound insulation, but is afraid of a humid environment. Therefore, after laying, a waterproofing layer of polyethylene film is laid on it. Of course, you can lay a underlay made of cheaper material - polystyrene. But it is quickly pressed during use, creating unevenness in the floor, up to breakage of the locking joint. Before laying the underlay, you should carefully study the manufacturer's instructions. Having decided on the type of underlay, you can start laying it. You should not completely lay the underlay in the entire room and in several layers. Its thickness should be no more than 3 mm. Along the wall, in the direction of laying the boards, lay a substrate, which is an insulating layer between the base and the laminate boards. The substrate with a top coating of aluminum foil is laid with the coating facing up. It is mandatory to lay a waterproofing layer of polyethylene under the substrate. It is attached with an overlap and fixed with tape or adhesive tape. Return to the table of contents</a>

Types of laminate locking systems:Click, Lock, UniClick. You can use polyethylene foam, extruded polystyrene foam or cork for the underlay. It is best to lay a underlay made of technical cork. The material is expensive and has good performance characteristics. It is highly wear-resistant and is poorly pressed. It has good heat and sound insulation, but is afraid of a humid environment. Therefore, after laying, a waterproofing layer of polyethylene film is laid on it. Of course, you can lay a underlay made of cheaper material - polystyrene. But it is quickly pressed during use, creating unevenness in the floor, up to breakage of the locking joint. Before laying the underlay, you should carefully study the manufacturer's instructions. Having decided on the type of underlay, you can start laying it. You should not completely lay the underlay in the entire room and in several layers. Its thickness should be no more than 3 mm. Along the wall, in the direction of laying the boards, lay a substrate, which is an insulating layer between the base and the laminate boards. The substrate with a top coating of aluminum foil is laid with the coating facing up. It is mandatory to lay a waterproofing layer of polyethylene under the substrate. It is attached with an overlap and fixed with tape or adhesive tape. Return to the table of contents</a>

Stelim laminate

Necessary tool:

- electric jigsaw;

- Grinder;

- a hammer;

- a wooden bar;

- level;

- fasteners.

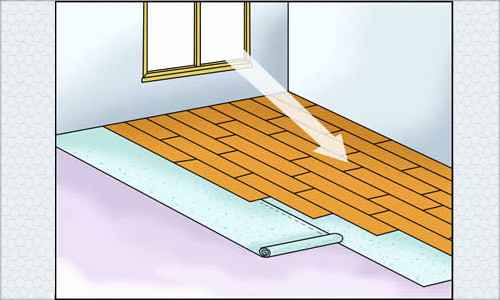

Laminate flooring must be laid in the directionlight from the window. This will make the joints of the panels less noticeable. After carrying out the preparatory work to level the base and purchasing the material in full, you can begin work. But before laying the laminate, it must lie in the room for at least 48 hours. You should begin laying work no earlier than 48 hours later. This is necessary so that the material can absorb the atmosphere and humidity of the room. You can begin laying the boards from any place in the room, but they must be placed in the direction of the light, from the window to the door. When laying, use one of the following methods:

Laminate flooring must be laid in the directionlight from the window. This will make the joints of the panels less noticeable. After carrying out the preparatory work to level the base and purchasing the material in full, you can begin work. But before laying the laminate, it must lie in the room for at least 48 hours. You should begin laying work no earlier than 48 hours later. This is necessary so that the material can absorb the atmosphere and humidity of the room. You can begin laying the boards from any place in the room, but they must be placed in the direction of the light, from the window to the door. When laying, use one of the following methods:

- lock connection;

- glued joint.

It is best to use laminate with a locking system.connection. If it is necessary to replace any board, the floor can be disassembled. The adhesive connection has one advantage - the resulting grooves will be filled with glue, which will increase the moisture resistance of the floor. But such a floor cannot be repaired, since the covering is monolithic. Laminate is laid along the cord, with the groove side to the wall, leaving a gap from the wall no more than 1.5 mm. For strength, wooden wedges are inserted into the gap. Having tightly connected the ends of the boards of the first row, they begin to lay the next row. If it is necessary to compact the joint, it is hammered through the attached wooden block. To increase the strength of the floor, the first board of the second row is cut to half its length. In the next row, they begin to lay the laminate again from a whole board. Gaps are eliminated by tamping the boards with a wooden block. If in the last row, near the wall, it is not possible to lay the board whole, then, having turned it over, it is necessary to mark its required width and cut it with a jigsaw. For hot and cold water supply pipes, cuts are made in the laminate. The size of the cut is made 2 cm larger than the diameter of the pipes. After finishing the laying work, the gap between the pipe and the material is closed with fittings. Return to the table of contents</a>

Installation of skirting boards

The skirting board is laid along the perimeter of the room.To attach it to the wall, use liquid nails or a dowel-screw. To find out how much baseboard is needed, you need to know the length of the perimeter of the room. Lay the baseboard, pressing it tightly to the wall. Mark the mounting locations. Drill holes and insert dowels, secure them with a screwdriver. The baseboard should fit equally tightly to both the wall and the laminate.