Plywood is probably one of the most uniqueconstruction and finishing materials. Its scope of application is practically unlimited, but it is used more as a rough version. However, the variety of its types and, above all, thickness can expand the scope of its application. Plywood lamps could become a completely organic interior detail, which even a person with minimal experience in hand-made can easily create with his own hands. However, certain knowledge of the manufacture and connection of electrical circuits will be required, but this problem can be easily solved with the help of an old lamp, from which you can take out all its internal filling. Plywood is an environmentally friendly material that allowscreate designer lamps with your own hands. Plywood is a completely natural material made from wood. It has quite high strength with a very small thickness. It lends itself well to processing, including burning. Also, on a sheet of plywood, using a jigsaw, you can cut out fancy patterns on the details, which can then turn into openwork interior items. On the market, plywood lamps are presented by several manufacturers and for interiors made in a variety of styles. They are especially relevant for ethnic, for example, Scandinavian style, but they can also be very organic for high-tech, if this is a combined option of plywood and metal. For interior balance, a pair may sometimes be needed: for example, a plywood chandelier can be supported by a sconce made in the same design, or various accessories, toys or even kitchen utensils.

Plywood is an environmentally friendly material that allowscreate designer lamps with your own hands. Plywood is a completely natural material made from wood. It has quite high strength with a very small thickness. It lends itself well to processing, including burning. Also, on a sheet of plywood, using a jigsaw, you can cut out fancy patterns on the details, which can then turn into openwork interior items. On the market, plywood lamps are presented by several manufacturers and for interiors made in a variety of styles. They are especially relevant for ethnic, for example, Scandinavian style, but they can also be very organic for high-tech, if this is a combined option of plywood and metal. For interior balance, a pair may sometimes be needed: for example, a plywood chandelier can be supported by a sconce made in the same design, or various accessories, toys or even kitchen utensils.

Tools and materials necessary for the manufacture of luminaires from plywood

For ideas with an openwork pattern, it is bestthin plywood will do, such a lamp will be light and elegant. To make an original and beautiful lamp or sconce from plywood, you will need the material itself, the thickness of which can be different depending on the design concept. Sometimes thicker plywood can be used for the base, for example, even 10 mm, and for making a lampshade, 3-4 mm is most convenient, since it does not weigh down the structure. You will also need to get a tool for the work. You will need an electric jigsaw, a set of different saws, a drill or a drill-screwdriver with a set of drills, a small hammer, sandpaper of different sizes. To glue the parts, you will need wood glue, casein glue or PVA, a brush. Additionally, you can prepare material for decoration, including paints. Although for plywood, treatment with colorless varnish is often quite sufficient, which protects the surface and more clearly reveals the structure of the material - the pattern of the wood. If you plan to apply a pattern by burning, you should also prepare a soldering iron. In addition, you should also prepare the electrical filling of the future lamp or light: parts for it can be purchased separately or use a ready-made scheme. For such plywood products, the choice of LED lamps can be very correct: economical and safe due to the fact that they practically do not contribute to the heating of the surface of the lampshades. Return to the table of contents</a>

For ideas with an openwork pattern, it is bestthin plywood will do, such a lamp will be light and elegant. To make an original and beautiful lamp or sconce from plywood, you will need the material itself, the thickness of which can be different depending on the design concept. Sometimes thicker plywood can be used for the base, for example, even 10 mm, and for making a lampshade, 3-4 mm is most convenient, since it does not weigh down the structure. You will also need to get a tool for the work. You will need an electric jigsaw, a set of different saws, a drill or a drill-screwdriver with a set of drills, a small hammer, sandpaper of different sizes. To glue the parts, you will need wood glue, casein glue or PVA, a brush. Additionally, you can prepare material for decoration, including paints. Although for plywood, treatment with colorless varnish is often quite sufficient, which protects the surface and more clearly reveals the structure of the material - the pattern of the wood. If you plan to apply a pattern by burning, you should also prepare a soldering iron. In addition, you should also prepare the electrical filling of the future lamp or light: parts for it can be purchased separately or use a ready-made scheme. For such plywood products, the choice of LED lamps can be very correct: economical and safe due to the fact that they practically do not contribute to the heating of the surface of the lampshades. Return to the table of contents</a>

Preparation of the sketch and manufacturing of details of the fixture

Plywood lamp diagram:1,2,3 — bracket parts. 4,5,6 — lampshade parts. For a beginner, it is best to choose model options with easier-to-implement parts. You can make something you came up with yourself or choose a model you like from any source: a magazine, the Internet, etc. It is desirable to have sketches of each part and instructions for making it. If there is only a diagram instead of a sketch, you first need to draw each part on a sheet in natural size and cut it out, then attach them to each other and make adjustments if necessary, and only then transfer the template drawing to a sheet of plywood. If your experience with a jigsaw is minimal, it is better to choose models without a large number of openwork elements. After all the parts have been transferred to the plywood, you can start sawing them out. The next step is to process them with sandpaper, first coarser, then fine, and finally, to ensure the smoothest possible surface, with “zero”. After this, each part can be covered with clear varnish or paint. It is important to take into account the fact that the surface may "bump up" - then it is necessary to go over the painted layer again with sandpaper, and then apply one or two more, depending on the required color intensity, layers of paint or varnish. Return to the table of contents</a>

Plywood lamp diagram:1,2,3 — bracket parts. 4,5,6 — lampshade parts. For a beginner, it is best to choose model options with easier-to-implement parts. You can make something you came up with yourself or choose a model you like from any source: a magazine, the Internet, etc. It is desirable to have sketches of each part and instructions for making it. If there is only a diagram instead of a sketch, you first need to draw each part on a sheet in natural size and cut it out, then attach them to each other and make adjustments if necessary, and only then transfer the template drawing to a sheet of plywood. If your experience with a jigsaw is minimal, it is better to choose models without a large number of openwork elements. After all the parts have been transferred to the plywood, you can start sawing them out. The next step is to process them with sandpaper, first coarser, then fine, and finally, to ensure the smoothest possible surface, with “zero”. After this, each part can be covered with clear varnish or paint. It is important to take into account the fact that the surface may "bump up" - then it is necessary to go over the painted layer again with sandpaper, and then apply one or two more, depending on the required color intensity, layers of paint or varnish. Return to the table of contents</a>

Assembling the lamp from the plywood own hands

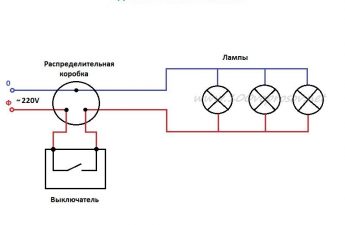

After applying the glue, the parts should be tightlypress together and secure with a clamp. To connect plywood parts, special adhesives intended for working with wood are used: wood glue or casein glue. As an option, it is quite acceptable to use PVA glue, but it does not guarantee high strength of the joints. When gluing parts, you need to carefully monitor the accuracy of the joints, especially the corner ones, since this can seriously affect the appearance of the future chandelier or sconce. Next, the prepared socket with the light bulb is mounted and the power cord is connected. After that, you can test the new interior item. Return to the table of contents</a>

After applying the glue, the parts should be tightlypress together and secure with a clamp. To connect plywood parts, special adhesives intended for working with wood are used: wood glue or casein glue. As an option, it is quite acceptable to use PVA glue, but it does not guarantee high strength of the joints. When gluing parts, you need to carefully monitor the accuracy of the joints, especially the corner ones, since this can seriously affect the appearance of the future chandelier or sconce. Next, the prepared socket with the light bulb is mounted and the power cord is connected. After that, you can test the new interior item. Return to the table of contents</a>

Simple models of luminaires from plywood

A beautiful chandelier or other lamp made ofDIY plywood lamps can become a real highlight of the interior. And for this, you don’t necessarily have to choose a complex or elaborate design. For example, a lamp in the form of a box with small holes for light can create a special coziness in the house, and it is easy to make from a sheet of thin plywood. Inside, you can install either a socket for a regular light bulb or an energy-saving one (it is more preferable, since it does not contribute to excessive heating of the walls of the plywood lampshade), or a circuit for an LED one. When assembling such a lamp, special attention should be paid to the joints: if the parts do not fit tightly together, then light will leak through the cracks, which will disrupt the entire harmony of the product. Fans of the oriental style will most likely like a minimalist lantern of a combined type made of plywood and fabric. But such a lamp is suitable not only for a Japanese or other oriental interior, it will quite logically fit into high-tech or even classics. The basis is a sheet of plywood, slats and fabric. The size of the lantern can be any, for a tabletop version you should stop at a side height of 15 to 35 cm. You can choose either a square or a rectangular shape. First, you should prepare the slats of the selected size, assemble them in the shape of a square or rectangle and attach the fabric to them. In total, you should get 5 parts: depending on the selected size and shape of the lamp, they can all be the same or different, for example, according to the following scheme 4 sides + 1 top, 2 sides + 2 sides + 1 top. From a sheet of plywood, you need to make a base on which the bulb socket will be attached. For such a lantern, for safety reasons, it is also better to give preference to energy-saving bulbs. The next step is to connect the wire with the plug and test it. If the result is positive, you can proceed to the final assembly. All parts are connected by gluing the slats together, which form the ribs of the lantern, and then the plywood bottom with a bulb is installed and fixed. You can make another version of this same lamp, in which both the bottom and the top will be plywood. And for the wall version, one side of the lantern should be made of plywood, which is what the lamp will be attached to the wall with.