The choice of linoleum as a floor coveringallows you to get a significant savings in the family budget with a practical and beautiful sex. Even more pleases thrifty owners the opportunity to avoid unnecessary costs for the invitation of the master for his styling. But for a really long and trouble-free operation of this material, you need to know how to properly lay the linoleum so that it will not be subjected to rapid wear and deformation.  Laying of antistatic linoleum.

Laying of antistatic linoleum.

Requirements for laying linoleum

A feature of this material for sex isamazing plasticity. Linoleum linen takes the form of any surface on which it is laid. The basis for it can serve almost any type of rough floor, fairly even and not having serious slopes, hillocks and pits. The only thing you should not do is try to lay the linoleum on the carpet - on a soft base the canvas will bend and stretch, and the legs of the furniture will quickly push the coating. In this case, you can, without removing the carpet, lay over it sheets of thick plywood. The resulting three-layer "pie" will create a good thermal and noise insulation in the room. The rules for laying such a floor are quite simple - smooth, dry foundation and unhurried, accurate work.  Floor construction with linoleum coating onsoil. A concrete base is considered ideal for any kind of flooring. Laying linoleum on concrete requires from the surface not only maximum evenness, but also the absence of cracks and potholes, especially when it comes to joining the floor with the walls. All damage must be repaired with a cement-sand mortar, and if they are too significant or the base has large deviations of the horizontal level, then it becomes necessary to carry out a cement screed. It should be noted that laying linoleum after this procedure can be carried out only when the solution is completely dry and set, otherwise the increased humidity of the base will lead to the appearance of mold and fungal microorganisms on the back of the material. You can check the presence of moisture in concrete in the old way - leave a piece of glass or a mirror on the surface overnight and check in the morning if water droplets have appeared on it. Another requirement for such a base is the complete absence of traces and stains of fatty, oil or paint and varnish origin. An old plank floor is considered completely suitable for use if it is stable, does not rot and the moisture content of the wood does not exceed 10-15%. The moisture content in the boards is checked with a special device - a moisture meter.

Floor construction with linoleum coating onsoil. A concrete base is considered ideal for any kind of flooring. Laying linoleum on concrete requires from the surface not only maximum evenness, but also the absence of cracks and potholes, especially when it comes to joining the floor with the walls. All damage must be repaired with a cement-sand mortar, and if they are too significant or the base has large deviations of the horizontal level, then it becomes necessary to carry out a cement screed. It should be noted that laying linoleum after this procedure can be carried out only when the solution is completely dry and set, otherwise the increased humidity of the base will lead to the appearance of mold and fungal microorganisms on the back of the material. You can check the presence of moisture in concrete in the old way - leave a piece of glass or a mirror on the surface overnight and check in the morning if water droplets have appeared on it. Another requirement for such a base is the complete absence of traces and stains of fatty, oil or paint and varnish origin. An old plank floor is considered completely suitable for use if it is stable, does not rot and the moisture content of the wood does not exceed 10-15%. The moisture content in the boards is checked with a special device - a moisture meter.  Preparing the floor for laying linoleum. Indicators exceeding the norm will indicate the prospect of the appearance of rot not only of the rough floor, but of the linoleum itself along with the adhesive composition. In this case, the wooden flooring will have to be dried by installing heaters in the room. Usually it takes up to 6 weeks. Loose boards are fixed with screws to lags, and in large slots in front of the putty lay narrow wooden slats or chips. Surface irregularities are eliminated by a planer, working in the longitudinal and transverse directions. If you plan to lay linoleum on the glue, the priming of the substrate is carried out to ensure better adhesion. The tile used as a foundation must meet all of the above requirements. Chopped tiles are subject to replacement, and peeled off - strengthening in their places. The slippery surface will not adhere well to mastic or glue, so it is notched on any hard and sharp object. Decide whether the old linoleum can serve as the basis for a new flooring, can only be after his careful examination. If the canvas has preserved its integrity and lies on a fairly level base, raise its edges and inspect the inside. Detected dirt and mold must be cleaned, dried and covered with a layer of soil. Back to contents</a>

Preparing the floor for laying linoleum. Indicators exceeding the norm will indicate the prospect of the appearance of rot not only of the rough floor, but of the linoleum itself along with the adhesive composition. In this case, the wooden flooring will have to be dried by installing heaters in the room. Usually it takes up to 6 weeks. Loose boards are fixed with screws to lags, and in large slots in front of the putty lay narrow wooden slats or chips. Surface irregularities are eliminated by a planer, working in the longitudinal and transverse directions. If you plan to lay linoleum on the glue, the priming of the substrate is carried out to ensure better adhesion. The tile used as a foundation must meet all of the above requirements. Chopped tiles are subject to replacement, and peeled off - strengthening in their places. The slippery surface will not adhere well to mastic or glue, so it is notched on any hard and sharp object. Decide whether the old linoleum can serve as the basis for a new flooring, can only be after his careful examination. If the canvas has preserved its integrity and lies on a fairly level base, raise its edges and inspect the inside. Detected dirt and mold must be cleaned, dried and covered with a layer of soil. Back to contents</a>

Selection of material and preparation of tools

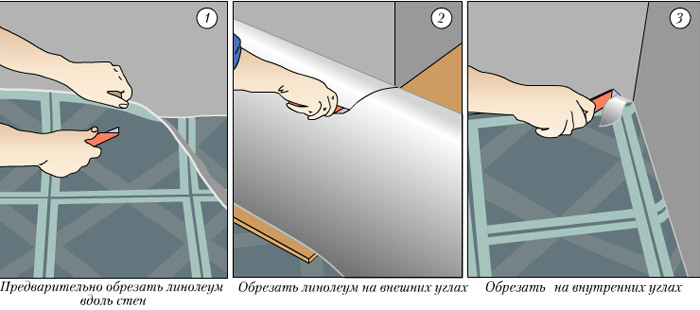

Pruning linoleum. This flooring received the name at the time when the linoleum was made only from natural materials. Now about 80% of this production is made from synthetic raw materials. Despite the high environmental performance, natural linoleum coating is in demand due to the high price and lack of flexibility. The ability to break in the process of transportation and operation makes its popularity low, despite the mass of other positive qualities. PVC coating has only 2 disadvantages: it does not tolerate critical temperatures and contact with acid and alkaline chemistry. Synthetic composition of the coating will not cause harm to the health of the inhabitants of the apartment, if its production complied with all accepted norms. Making a choice when buying, it should be taken into account that there are two types of linoleum - homogeneous, that is, baseless, and heterogeneous, the back of which has a substrate. The homogeneous type is thin, and to ensure the thermal and moisture-insulating ability of the floor, it is better to purchase a substrate for laying between the roughing base and the material.

Pruning linoleum. This flooring received the name at the time when the linoleum was made only from natural materials. Now about 80% of this production is made from synthetic raw materials. Despite the high environmental performance, natural linoleum coating is in demand due to the high price and lack of flexibility. The ability to break in the process of transportation and operation makes its popularity low, despite the mass of other positive qualities. PVC coating has only 2 disadvantages: it does not tolerate critical temperatures and contact with acid and alkaline chemistry. Synthetic composition of the coating will not cause harm to the health of the inhabitants of the apartment, if its production complied with all accepted norms. Making a choice when buying, it should be taken into account that there are two types of linoleum - homogeneous, that is, baseless, and heterogeneous, the back of which has a substrate. The homogeneous type is thin, and to ensure the thermal and moisture-insulating ability of the floor, it is better to purchase a substrate for laying between the roughing base and the material.  Scheme laying linoleum. The heterogeneous species has two types of internal processing. Foam base is more durable, and fabric (jute) - is a good heat insulator, but less durable and subject to humidity. Stop selection on a certain type of product will help evaluate the features of the room and the operating conditions of the future floor. In the process of laying linoleum cover, you will need an approximate set of tools and additional materials:

Scheme laying linoleum. The heterogeneous species has two types of internal processing. Foam base is more durable, and fabric (jute) - is a good heat insulator, but less durable and subject to humidity. Stop selection on a certain type of product will help evaluate the features of the room and the operating conditions of the future floor. In the process of laying linoleum cover, you will need an approximate set of tools and additional materials:

- a special knife with replaceable blades;

- rubber roller;

- Ruler;

- double sided tape;

- glutinous mastic;

- paper tape;

- adhesive for joints;

- notched trowel for applying mastic.

Back to contents</a>

The laying process of linoleum flooring

Tools for laying linoleum. The direction of the material webs depends on the pattern, but it is better to use the longitudinal arrangement of the strips in narrow and long spaces. If the room has contours of complex shape, it is better to make a test layout for determining the exact cutting. Cut out the necessary parts for depressions, protrusions or pipes will help a pre-made cardboard or paper template. Delivered from the store roll will need to be flattened in the room where the laying is planned, for a couple of days, letting the material acclimatize to room temperature, and its surface - to straighten. When cutting, do not neglect the small stock left. Can not get to properly lay linoleum because of irregularities in the perimeter, and it is better to later cut off the extra centimeters. Lay the coating in two ways - "dry" method and glue. The first option is suitable only for a small area, but even in this case it is necessary to fix the panel to the base with a double-sided adhesive tape. With the use of this technology, it is especially important that there is no dust and small debris on the substrate. One side of the adhesive tape is glued to the floor, then parts are removed from it by the top protection and gradually unfold the roll in the desired direction, pressing the material. Adhesive tape in this case should form a lattice for the most qualitative fixation of linoleum. The skirting boards installed along the perimeter finally fix the cover in place. When using the glue method, a distance of 0.5-1 cm between the wall and the cloth is left to prevent the appearance of blisters with natural expansion. Mastic is applied to the surface of the base with a notched trowel and proceeds to glue the first roll, unfolding it from the far corner to the door. In the process, smooth the cloth, trying from the center to the edge to expel excess air and glue. This can be done with a rubber roller or simply a thick, not too soft cloth. The next roll is laid in the same way, with the application of 1,5-2 cm of material on the surface of the first web. After the flooring of the entire coating should take 2-3 days until the moment when it will be possible to decorate and glue the joints. To ensure the strength of joints, they are treated with special glue, which is called "cold welding". Secure roll edges from getting this tool will help paper tape, which is cut at the junction and removed after filling the seam with glue.

Tools for laying linoleum. The direction of the material webs depends on the pattern, but it is better to use the longitudinal arrangement of the strips in narrow and long spaces. If the room has contours of complex shape, it is better to make a test layout for determining the exact cutting. Cut out the necessary parts for depressions, protrusions or pipes will help a pre-made cardboard or paper template. Delivered from the store roll will need to be flattened in the room where the laying is planned, for a couple of days, letting the material acclimatize to room temperature, and its surface - to straighten. When cutting, do not neglect the small stock left. Can not get to properly lay linoleum because of irregularities in the perimeter, and it is better to later cut off the extra centimeters. Lay the coating in two ways - "dry" method and glue. The first option is suitable only for a small area, but even in this case it is necessary to fix the panel to the base with a double-sided adhesive tape. With the use of this technology, it is especially important that there is no dust and small debris on the substrate. One side of the adhesive tape is glued to the floor, then parts are removed from it by the top protection and gradually unfold the roll in the desired direction, pressing the material. Adhesive tape in this case should form a lattice for the most qualitative fixation of linoleum. The skirting boards installed along the perimeter finally fix the cover in place. When using the glue method, a distance of 0.5-1 cm between the wall and the cloth is left to prevent the appearance of blisters with natural expansion. Mastic is applied to the surface of the base with a notched trowel and proceeds to glue the first roll, unfolding it from the far corner to the door. In the process, smooth the cloth, trying from the center to the edge to expel excess air and glue. This can be done with a rubber roller or simply a thick, not too soft cloth. The next roll is laid in the same way, with the application of 1,5-2 cm of material on the surface of the first web. After the flooring of the entire coating should take 2-3 days until the moment when it will be possible to decorate and glue the joints. To ensure the strength of joints, they are treated with special glue, which is called "cold welding". Secure roll edges from getting this tool will help paper tape, which is cut at the junction and removed after filling the seam with glue.