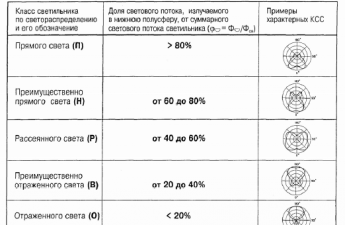

In modern design, sconces, chandeliers are used, andalso spotlights, which are capable of providing a certain area with the necessary flow of light. All electrical devices, which include lighting, have their own installation features. However, connecting spotlights with your own hands is quite possible, but subject to compliance with the work technology, as well as safety measures. Wiring diagram for spot ceiling lights to 220V current.

Wiring diagram for spot ceiling lights to 220V current.

Some nuances of installation

When installing spotlights, the features of the ceiling covering should be taken into account. For example, if the building material used for finishing the ceiling is flammable, then the following should be taken into account: For wiring lighting fixtures, special heat-resistant wires must be used.

For wiring lighting fixtures, special heat-resistant wires must be used.

- for wiring for lighting devices, special wires must be used which are heat resistant;

- the connection of the wiring when connecting the spotlights must be reliable and isolated;

- the power of the lamps that are used must match the technical characteristics of the wires, otherwise they will be subject to excessive overheating.

When choosing wires for connecting spotlights, you must be guided by the following criteria:

- they should not burn;

- should be resistant to prolonged exposure to high temperatures.

The cable meets these requirements,which the outer layer of the braid is made of fiberglass, and the inner insulation is made of high-strength organic rubber. These wires allow you to install a spotlight in any room, such as kitchens, saunas, baths, bathrooms, and in unlimited quantities within reasonable limits. To ensure the reliability of the wire connection during installation, you can use a special tool - a crimping press. It connects cables using hollow copper sleeves, which serve as reliable insulation. An alternative to the press can be pliers, which are identical in principle to it. Return to the table of contents</a>

Necessary materials and tools

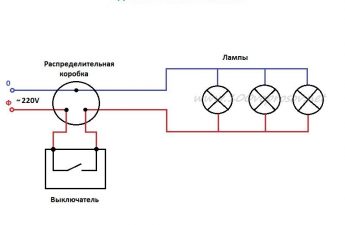

Connecting spotlights requires the following tools and materials, such as: Options for connecting spotlights.

Options for connecting spotlights.

- lighting;

- supply wire, switch;

- special connecting elements (terminals or sleeves);

- insulating tape or heat shrink tubing;

- pliers;

- a drill with a special nozzle (if the ceiling is made of plasterboard, laminate, plywood);

- tape measure, pencil.

Spotlights within one roomare selected identically. This provides more correct lighting in the room and supports the overall picture of the interior. It is necessary to take into account the presence of a reflective layer in the lamp, which provides increased light output. For spotlights, lamps with a power of no more than 40 W are most often chosen. This provides good lighting due to the fact that such lighting devices are installed at a fairly close distance from each other. Return to contents</a>

Stages of installation of spotlights

The connection process comes down to the sequential execution of the following steps: Stages of connecting a spotlight.

Stages of connecting a spotlight.

- design and marking;

- laying and pulling cables to the installation site;

- making holes and connecting;

- testing of connections.

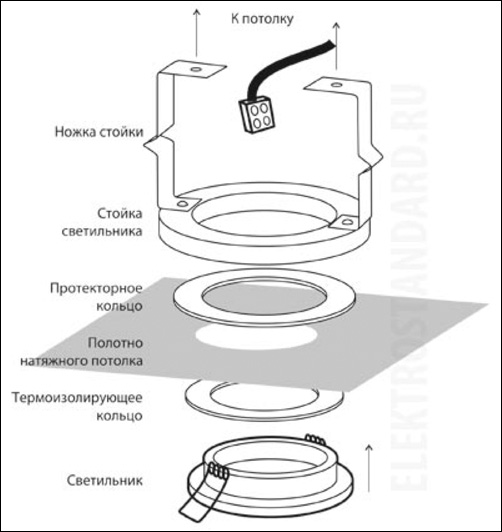

This detailed breakdown into stages is related tothat some of the work must be done when forming the ceiling covering. Planning the locations of the lamps is done before covering it with finishing material, that is, during the installation of the frame. Designing takes on special meaning if there are several levels near the ceiling. In this case, it is necessary to provide for wiring in the places where the lamps are attached at each level, taking into account the distribution of the light flux. Lamps that are located within one level must form one single contour. When planning the number of spotlights that will provide the required illumination of the space, it is necessary to take into account that the distance from the wall to them should be no more than 60 cm, and the distance between the centers - 25-30 cm. At the same time, the lamp should be at least 30 cm from the frame. If the lamp is located closer to the frame, then its installation at the final stage may be difficult. The structure of the lamp.The presence and location of other lighting fixtures in the room affects the final number of lamps. A spotlight can be equipped with a rotation mechanism, with the help of which the direction of the light flow can be changed. Therefore, they can be diverted when using several lamps at the same time. The wiring is laid at the stage of installing the frame. It is placed in special boxes or fixed to it in such a way that it is easy to get it out when making holes for spotlights. If it is not possible to choose places for installing spotlights during the installation of the frame, then you can lay the cable only to 1 lamp. And each subsequent spotlight is connected to the previous one, pulling the wire through the already mounted ceiling covering. But this method of wiring somewhat violates safety precautions, since the wires remain lying directly on the surface of the suspended ceiling. When laying a cable along the frame or in protective boxes, you can use 2 or 3 cores. A loop for attaching each spotlight is left 10-15 cm long. It is attached to the frame near the location of the spotlight using a plastic tie. But the fastening should not be tight, so as not to cause difficulties when dismantling it during the final connection. Drilling holes for each spotlight is carried out after completing the installation of the ceiling. Correct design of the locations of the spotlights allows you to avoid their placement on metal elements of the frame. In addition, if the spotlight is located at the joint between the sheathing sheets, it should be moved or the sheets should be redistributed so that the joint is moved to the required distance. To ensure that all the spots are located exactly along the line, pre-mark with a tape measure and a pencil.

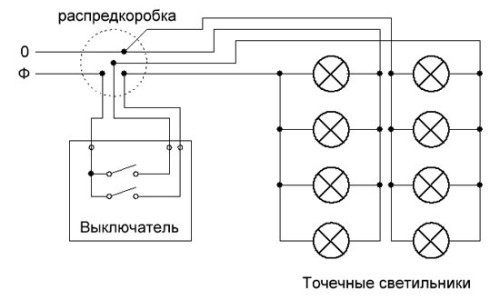

The structure of the lamp.The presence and location of other lighting fixtures in the room affects the final number of lamps. A spotlight can be equipped with a rotation mechanism, with the help of which the direction of the light flow can be changed. Therefore, they can be diverted when using several lamps at the same time. The wiring is laid at the stage of installing the frame. It is placed in special boxes or fixed to it in such a way that it is easy to get it out when making holes for spotlights. If it is not possible to choose places for installing spotlights during the installation of the frame, then you can lay the cable only to 1 lamp. And each subsequent spotlight is connected to the previous one, pulling the wire through the already mounted ceiling covering. But this method of wiring somewhat violates safety precautions, since the wires remain lying directly on the surface of the suspended ceiling. When laying a cable along the frame or in protective boxes, you can use 2 or 3 cores. A loop for attaching each spotlight is left 10-15 cm long. It is attached to the frame near the location of the spotlight using a plastic tie. But the fastening should not be tight, so as not to cause difficulties when dismantling it during the final connection. Drilling holes for each spotlight is carried out after completing the installation of the ceiling. Correct design of the locations of the spotlights allows you to avoid their placement on metal elements of the frame. In addition, if the spotlight is located at the joint between the sheathing sheets, it should be moved or the sheets should be redistributed so that the joint is moved to the required distance. To ensure that all the spots are located exactly along the line, pre-mark with a tape measure and a pencil. Connection diagram for several groups of lamps.The holes are drilled with a drill with a special attachment - a hole saw, the central drill of which is installed in the center of the lamp. A perfectly even circle is formed, which helps to avoid unnecessary gaps. The diameter of such a saw should be 3-4 mm smaller than the corresponding external size of the lamp, but 3-4 mm larger than the internal dimensions. After all the holes are drilled, it is necessary to get the loop of wire that was left to attach the spotlight. If such loops were not made or the wiring for each spotlight is not connected, then it is necessary to pull the cable to them. Pulling the wire should begin from the outermost lamp, gradually moving further along the line of their installation. This can be done with a hook, which is made of strong wire. Return to the table of contents</a>

Connection diagram for several groups of lamps.The holes are drilled with a drill with a special attachment - a hole saw, the central drill of which is installed in the center of the lamp. A perfectly even circle is formed, which helps to avoid unnecessary gaps. The diameter of such a saw should be 3-4 mm smaller than the corresponding external size of the lamp, but 3-4 mm larger than the internal dimensions. After all the holes are drilled, it is necessary to get the loop of wire that was left to attach the spotlight. If such loops were not made or the wiring for each spotlight is not connected, then it is necessary to pull the cable to them. Pulling the wire should begin from the outermost lamp, gradually moving further along the line of their installation. This can be done with a hook, which is made of strong wire. Return to the table of contents</a>

Concluding moments of the workflow

After laying the wire or pulling out the loopit is necessary to free the wire from the insulating layer for further fastening. These bare wires are clamped in the lamp terminal according to the connection diagram, which is attached to the device. There are markings on the spot, according to which connections must be made: L - phase wire, N - neutral wire, PE - grounding. At this stage, everything must be done carefully, accurately and technically correctly, observing all safety precautions. After connecting to the power supply, it is necessary to insert the spotlight into the hole, slightly bending the clamps of the structure. This will allow it to enter tightly enough, without forming gaps between the lamp cover and the hole in the ceiling. In this case, it is necessary to ensure that the fastening wires do not fall between the brackets. After this, the power wire is connected to the switch, the bulbs are screwed in and a test run is performed. As soon as all the lamps are lit, the installation is considered complete.