If you choose a material for replacing a floor, relying onon the criteria of affordable price, durability, ease of maintenance and the possibility of self-installation, then laminate flooring fits this description best. A reliable and durable structure will decorate any home, and laying laminate flooring with your own hands will not be difficult even for a person who is not very familiar with repair work. But to get a high-quality result, you need to choose the right laminate, carefully prepare for its installation and take into account some rules that will help you avoid making mistakes when performing this process. With the help of laminate you can create a durable, beautiful and reliable floor covering.

With the help of laminate you can create a durable, beautiful and reliable floor covering.

Classification of laminated flooring

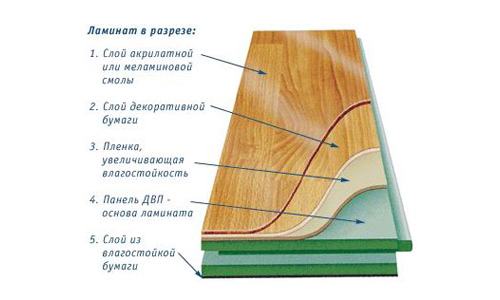

Before purchasing laminate flooring, it would be useful toget acquainted with some information about this type of flooring. The price of the products varies and depends not only on the manufacturer, but also on its type and class. Types of laminate.All of it is manufactured using practically the same technology, which involves soldering high-density fiberboard with decorative and stabilizing layers. This happens under high temperature and pressure conditions, and the result is a board famous for its high functional characteristics and excellent aesthetics. Depending on the components used and the features of the production process, laminate acquires specific strength and wear resistance indicators. This leads to its division into classes from 31 to 34. Higher indicators allow the use of the coating in rooms with a high load on the surface, but the price of such material is also higher. If you are planning a laminate floor in an apartment or house, it makes no sense to buy a high-class product. For this purpose, 31 or 32 markings according to the classification are quite sufficient. Return to the table of contents</a>

Types of laminate.All of it is manufactured using practically the same technology, which involves soldering high-density fiberboard with decorative and stabilizing layers. This happens under high temperature and pressure conditions, and the result is a board famous for its high functional characteristics and excellent aesthetics. Depending on the components used and the features of the production process, laminate acquires specific strength and wear resistance indicators. This leads to its division into classes from 31 to 34. Higher indicators allow the use of the coating in rooms with a high load on the surface, but the price of such material is also higher. If you are planning a laminate floor in an apartment or house, it makes no sense to buy a high-class product. For this purpose, 31 or 32 markings according to the classification are quite sufficient. Return to the table of contents</a>

Choose a laminate cover

Layout of the laminate.An exception can be made if it is planned in the kitchen or bathroom. These rooms are characterized by high humidity, and only waterproof types of flooring will be able to withstand constant contact with water and frequent cleaning. It is worth noting that water resistance and moisture resistance of laminated flooring are two different concepts. The latter type can only survive high air humidity and a very short-term presence of water on the surface. Waterproof material also does not have absolute resistance to liquid, but easily tolerates flooding with water for several hours, after which it can be dried without losing its shape and appearance. When buying laminate, you should pay attention to the manufacturer of the product. Well-known companies value their reputation, their products meet European standards and have a long, and sometimes even lifetime warranty period. Full control of the production process and the use of environmentally friendly components allow the floor to have decent quality and complete safety for human health. Laminated flooring produced without observing the rules and regulations can be identified by the pungent smell of formaldehyde. The prohibited and dangerous to health drug can be contained only in low-quality laminate. Return to contents</a>

Layout of the laminate.An exception can be made if it is planned in the kitchen or bathroom. These rooms are characterized by high humidity, and only waterproof types of flooring will be able to withstand constant contact with water and frequent cleaning. It is worth noting that water resistance and moisture resistance of laminated flooring are two different concepts. The latter type can only survive high air humidity and a very short-term presence of water on the surface. Waterproof material also does not have absolute resistance to liquid, but easily tolerates flooding with water for several hours, after which it can be dried without losing its shape and appearance. When buying laminate, you should pay attention to the manufacturer of the product. Well-known companies value their reputation, their products meet European standards and have a long, and sometimes even lifetime warranty period. Full control of the production process and the use of environmentally friendly components allow the floor to have decent quality and complete safety for human health. Laminated flooring produced without observing the rules and regulations can be identified by the pungent smell of formaldehyde. The prohibited and dangerous to health drug can be contained only in low-quality laminate. Return to contents</a>

Preparing the floor for laying

The main condition that must be strictly observed when laying laminate flooring with your own hands concerns the preparation of the base. Tools for laying laminate flooring.Any type of surface is suitable for installation of the covering, the only exception is too soft carpet. The main requirements for the condition of the subfloor can be summarized in several points:

Tools for laying laminate flooring.Any type of surface is suitable for installation of the covering, the only exception is too soft carpet. The main requirements for the condition of the subfloor can be summarized in several points:

If the listed requirements are not metconcrete base and its restoration will not lead to the required horizontal level indicators, then in this case it will be impossible to do without a cement screed. The old plank floor can be strengthened by fixing the boards to the joists with screws or nails, and wide cracks can be repaired with small chips and putty. The main thing is that the boards are not rotten and hold their shape. Linoleum is inspected from the back side, and if there are traces of mold on it, it is primed as far as possible from the edge. Fallen ceramic tiles are glued back in place, and chips and cracks are putty or treated with tile adhesive. Return to contents</a>

Substrate for laying the laminate with your own hands

Laminate flooring installation technology.The manufacturers' insistent recommendation to use a backing when installing laminate flooring is not an advertising ploy, but a way to extend the life of the laminate and make its use more comfortable. This material is not that expensive, but has very important properties:

Laminate flooring installation technology.The manufacturers' insistent recommendation to use a backing when installing laminate flooring is not an advertising ploy, but a way to extend the life of the laminate and make its use more comfortable. This material is not that expensive, but has very important properties:

- ability to hide small surface irregularities;

- waterproofing;

- soundproofing;

- prevention of the appearance of insects and microorganisms;

- shock absorption during walking.

Different types of substrates are designed foruse in specific room conditions. The cheapest option is single-layer foamed polyethylene. It does not have a long service life due to its high wrinkling. The substrate, consisting of polystyrene and aluminum foil, has good properties. Its antiseptic and moisture-proof properties correspond to the cost and make it the most suitable for laying laminate. There are several other varieties of this material: cork, bitumen-cork, composite and extruded polystyrene foam. They are distinguished by different functional features, but the price of this product is higher than that of ordinary types. Return to contents</a>

Tools for laying laminate

Schemes for laying laminate flooring in various ways.You cannot start laying laminated boards immediately after delivery. The packages should be laid out in the room where the floor will be installed, and the material should be given the opportunity to adapt to the new humidity and temperature conditions for 2-3 days. During this time, you can prepare the tools needed for the job:

Schemes for laying laminate flooring in various ways.You cannot start laying laminated boards immediately after delivery. The packages should be laid out in the room where the floor will be installed, and the material should be given the opportunity to adapt to the new humidity and temperature conditions for 2-3 days. During this time, you can prepare the tools needed for the job:

- electric jigsaw;

- drill with feather drills on wood;

- pencil with soft lead;

- ruler, gon and roulette;

- a hammer;

- podbivochny wooden bar;

- wooden wedges;

- clamp.

There is a special device -a machine for cutting laminate. But the advisability of its purchase is questioned by 2 facts. Firstly, it can only cut panels crosswise, so it will not work to reduce the width of the boards of the outer rows, you will still have to use a jigsaw. And secondly, is it worth spending money on a device that will be used very rarely in the household. If you do not have a jigsaw at hand, you can replace it with a hacksaw, but the teeth must be very small, otherwise the film on the surface of the laminate will be damaged. Return to contents</a>

The process of installing a laminate coating

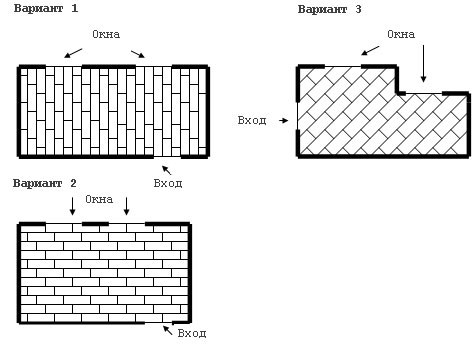

Sequence of laying laminate.Before you start laying laminated panels yourself, you need to carefully lay out the underlay on a clean and dry base. The strips should overlap by 6-10 cm, and their edges should be secured with tape so that they do not get knocked down during work. There should be a gap of at least 1 cm between all the walls and the laminated flooring. It will perform the function of a compensation gap during the natural change in the size of the panels under the influence of climatic changes at different times of the year. The installation scheme for laminated flooring has three options: longitudinal, transverse and diagonal. The first method is the simplest and can be performed using the classic method or in a checkerboard pattern. The classic arrangement of panels is practically waste-free due to the fact that the remainder of the first row will serve as the beginning of the second. Therefore, for the first experience, it is better to use the simple option.

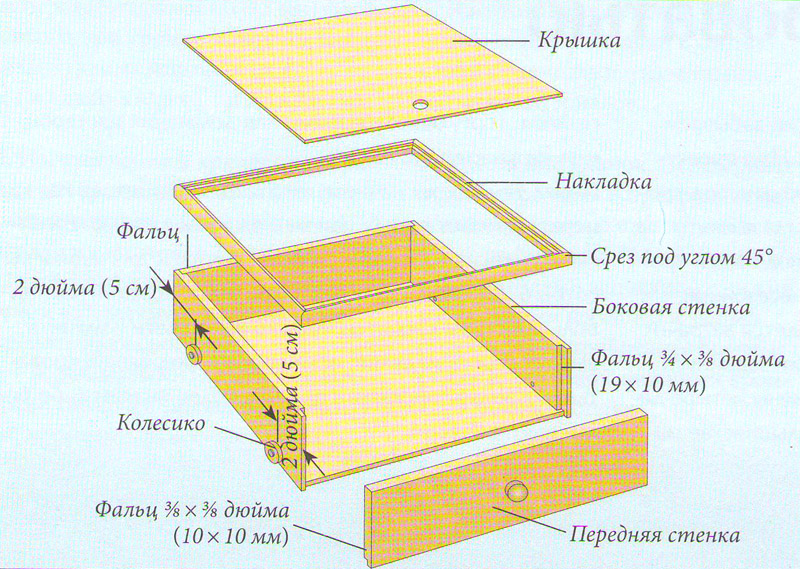

Sequence of laying laminate.Before you start laying laminated panels yourself, you need to carefully lay out the underlay on a clean and dry base. The strips should overlap by 6-10 cm, and their edges should be secured with tape so that they do not get knocked down during work. There should be a gap of at least 1 cm between all the walls and the laminated flooring. It will perform the function of a compensation gap during the natural change in the size of the panels under the influence of climatic changes at different times of the year. The installation scheme for laminated flooring has three options: longitudinal, transverse and diagonal. The first method is the simplest and can be performed using the classic method or in a checkerboard pattern. The classic arrangement of panels is practically waste-free due to the fact that the remainder of the first row will serve as the beginning of the second. Therefore, for the first experience, it is better to use the simple option. Rules for laying laminate near door framesand pipes. The first row of boards should be facing the wall with the groove. You can choose its direction empirically, placing the panels alternately along or across the room. The light falling from the window will show how the joints at their ends will look better. Additionally, take into account the interior features and the arrangement of furniture in the room. In order not to face the fact that the last row will be too narrow, it is worth counting the number of strips and, if necessary, cutting the first boards to width. Then the width of the outer rows will become proportional. Lamels are easily connected to each other using the locking method. They are brought end to end, making sure that the comb on the other board is turned to the groove on one board. The connection occurs at an angle of 45 ° and is considered successful if a characteristic click is heard, indicating high-quality contact. The last board is brought to the desired size with a jigsaw, and the assembly of the second row begins with its remainder. For good density, the strips are knocked down with light taps of a hammer, placing a wooden block underneath them. The last row is installed using wooden wedges and a clamp. It is most convenient to make holes for heating pipes with a drill equipped with wood feather drills. The final stage of the work will be the installation of skirting boards and thresholds. It is better to buy these parts at the same time as the laminated flooring, so that you can perfectly select the right shade and texture. Skirting boards can only be attached to the wall, not to the floor covering. If you screw the skirting board to the laminate, it will lose the ability to freely change dimensions when the temperature and humidity change. And the adhesive method of fastening will deprive the material of one of its main advantages - the ability to dismantle and move to another room if necessary.</ ul>

Rules for laying laminate near door framesand pipes. The first row of boards should be facing the wall with the groove. You can choose its direction empirically, placing the panels alternately along or across the room. The light falling from the window will show how the joints at their ends will look better. Additionally, take into account the interior features and the arrangement of furniture in the room. In order not to face the fact that the last row will be too narrow, it is worth counting the number of strips and, if necessary, cutting the first boards to width. Then the width of the outer rows will become proportional. Lamels are easily connected to each other using the locking method. They are brought end to end, making sure that the comb on the other board is turned to the groove on one board. The connection occurs at an angle of 45 ° and is considered successful if a characteristic click is heard, indicating high-quality contact. The last board is brought to the desired size with a jigsaw, and the assembly of the second row begins with its remainder. For good density, the strips are knocked down with light taps of a hammer, placing a wooden block underneath them. The last row is installed using wooden wedges and a clamp. It is most convenient to make holes for heating pipes with a drill equipped with wood feather drills. The final stage of the work will be the installation of skirting boards and thresholds. It is better to buy these parts at the same time as the laminated flooring, so that you can perfectly select the right shade and texture. Skirting boards can only be attached to the wall, not to the floor covering. If you screw the skirting board to the laminate, it will lose the ability to freely change dimensions when the temperature and humidity change. And the adhesive method of fastening will deprive the material of one of its main advantages - the ability to dismantle and move to another room if necessary.</ ul>